Summary of HIR Equipment (2012-2013) - High Impact Research

Summary of HIR Equipment (2012-2013) - High Impact Research

Summary of HIR Equipment (2012-2013) - High Impact Research

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

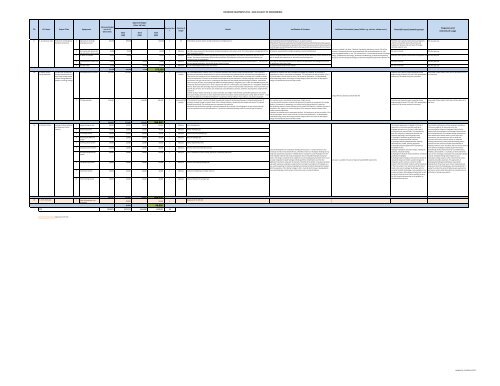

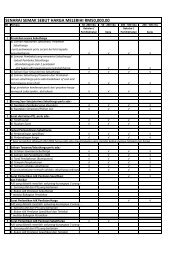

<strong>HIR</strong>-MOHE EQUIPMENT <strong>2012</strong> - <strong>2013</strong> (FACULTY OF ENGINEERING)Approved BudgetNoPI's NameProject Titles<strong>Equipment</strong>sEstimated BudgetYear 2 & 3(<strong>2012</strong>-<strong>2013</strong>)<strong>2012</strong>(RM)(After VM Lab)<strong>2013</strong>(RM)Total(RM)Quantity/Uni Country <strong>of</strong>tOriginDetails Justification <strong>of</strong> Purchase Additional Information (space/utilities e.g. electric, s<strong>of</strong>tware etc.) Potential users/research groupsFrequency andintensity <strong>of</strong> usage17Pr<strong>of</strong>.Dr Dr. Jaya Mohd Narayan Hamdi Sahu Production <strong>of</strong> hydrogen byAbd Shukorhydrolysis <strong>of</strong> biomass1 <strong>High</strong> pressure and high200,000 200,000200,000 1 UK Intermediate pyrolysis reactor at high temperature and high pressure IntermediatePyrolysisIntermediatePyrolysis is an advance version.Potential users typically involve chemical engineers, 325 days per yeartemperature reactorThefeedstocksthatcanbeusedarediverseandrangefromwastewoodt<strong>of</strong>oodwastesandsewagesludchemist, and scientist deals with pyrolysis and-ge.Thereisalsosolidresidue(biochar)asaproductfromthepyrolysisprocesswhichcanbeusedasafertihydrolysis <strong>of</strong> biomass and solid waste for biogasliserfortheagriculturalfields(aperfectcaseforcarbonsequestration)oritcanbeusedforcocombustiosynthesis research work.ninthermalpowerplants.Lab space available in W block, Chemical Engineering department, kinetic S/W will bepurchase. This experimental set-up generates data that can be published in tier 1 ISI2 HPLC pump and rapture disc10,000 10,00010,000 1 Malaysia The HPLC pump required for the transport <strong>of</strong> liquid oil products to the column <strong>of</strong> GC. The control system arrangement for the Accessories required forGC and high temperature reactor establishment All users in the lab. 325 days per year-and valve with control systemhigh temperature reactor.journals targeted number 17 and lists <strong>of</strong> journals are: 1) International Journal <strong>of</strong> hydrogenEnergy; 2) Bioresource Technology; 3) Biomass and Bioenergy; 4) Chemical Engineering3 GC with TCD column 90,000 90,00090,000 1 Malaysia After the components <strong>of</strong> a mixture are separated using gas chromatography, they must be detected as they exit the GC Analysis the gases product online with the reactor use for the hydrolysis process, which will bePotential users typically involve chemical engineers, chemist, 325 days and scientist per yearwho require automated detection bio- syngas research work.-column. The thermal-conductivity (TCD) and flame-ionization (FID) detectors are the two most common detectors onable to identify the components <strong>of</strong> fuel mixture and hydrogen, etc.Journal; 5) Fuel Processing Technology; 6) Industrial & Engineering Chemistry <strong>Research</strong> etc.commercial gas chromatographs.To store the data collected from GC 4 Data acquisition system with50,00050,000 50,000 1 Malaysia after the analysis <strong>of</strong> gases products from the reactor for further analysis’s . Two S/W use This is use as supporting requirements for process and experiment data storage and analysisAll users in the lab.325 days per year-PCfor store process parameter data and for kinetic analysis <strong>of</strong> data.for equilibrium and kinetic study.5 Gas flow meter 25,000 - 25,000 25,000 1 Malaysia Use for majoring gas products flow rate online. Quantify the gases product from reactor All users in the lab. 325 days per year375,000 300,000 75,000 375,00018 Dr Hendrik SimonCornelis MetselaarThermal and melting heattransfer characteristics in alatent heat storage system<strong>of</strong> Phase Change Material(PCM) as an energy storage1 Thermogravimetric Analyzer 341,400 341,400 - 341,400 1 Germany/USA/S The Thermogravimetric Analyzer (TGA) is an essential laboratory tool used for material characterization. TGA is used as a Measures the amount and rate <strong>of</strong> change in the weight <strong>of</strong> a material as a function <strong>of</strong>weeden technique to characterize materials used in various environmental, food, pharmaceutical, and petrochemical applications. A temperature or time in a controlled atmosphere. This equipment can help to publish 5 Tier 1TGA consists <strong>of</strong> a sample pan that is supported by a precision balance. That pan resides in a furnace and is heated or cooled ISI journal papers. Here is some list <strong>of</strong> tier 1 ISI journal for publication. 1st Renewable &during the experiment. The mass <strong>of</strong> the sample is monitored during the experiment. A sample purge gas controls the sample sustainable energy review 2nd energy 3rd solar energy material and solar cell 4th Appliedenvironment. This gas may be inert or a reactive gas that flows over the sample and exits through an exhaust. PerkinElmer energy 5th International journal <strong>of</strong> heat transfer<strong>of</strong>fers two types <strong>of</strong> TGAs, a top-loading TGA 4000 and a bottomloading or hangdown, Pyris 1 TGA. The TGA 4000 supports thesample pan above the balance via a “stem” support rod. The Pyris 1 TGA supports the sample pan via a “hangdown” below thebalance. Both styles take advantage <strong>of</strong> gravity to obtain very accurate and reproducible measurements. These instruments canquantify loss <strong>of</strong> water, loss <strong>of</strong> solvent, loss <strong>of</strong> plasticizer, decarboxylation, pyrolysis, oxidation, decomposition, weight % filler,amount <strong>of</strong>metallic catalytic residue remaining on carbon nanotubes, and weight % ash.All these quantifiable applications are usuallydone upon heating, but there are some experiments where information may be obtained upon cooling. Both the Pyris 1 TGAEnergy Efficiency laboratory (level2 Blok M)and the TGA 4000 are controlled by PerkinElmer’s proprietary thermal s<strong>of</strong>tware, Pyris S<strong>of</strong>tware, and have autosampleraccessories for unattended operation2 FTIR Spectrometer 248,400 - 248,400 248,400 1 Germany/USA/S FT-IR stands for Fourier Transform InfraRed, the preferred method <strong>of</strong> infrared spectroscopy. In infrared spectroscopy, IR This machine use for characterize the spectrum <strong>of</strong> light sourcesweeden radiation is passed through a sample. Some <strong>of</strong> the infrared radiation is absorbed by the sample and some <strong>of</strong> it is passed It can also identify unknown materials and determine the quality or consistency <strong>of</strong> a samplethrough (transmitted). The resulting spectrum represents the molecularBesides, the amount <strong>of</strong> components in a mixture can be determined by this machineabsorption and transmission,creating a molecular fingerprint <strong>of</strong> the sample. Like a fingerprint no two unique molecular The qualitative analysis <strong>of</strong> every different kind <strong>of</strong> material will identify. In addition, the size <strong>of</strong>structures produce the same infrared spectrum. This makes infrared spectroscopy useful for several types <strong>of</strong> analysis.the peaks in the spectrum is a direct indication <strong>of</strong> the amount <strong>of</strong> material present. Withmodern s<strong>of</strong>tware algorithms,infrared is an excellent tool for quantitative analysis. This equipment can help to publish 5 Tier1 ISI journal papers. Here is some list <strong>of</strong> tier 1 ISI journal for publication. 1st Renewable &sustainable energy review 2nd energy 3rd solar energy material and solar cell 4th Appliedenergy 5th International journal <strong>of</strong> heat transfer.Potential users typically involve reseachers doing Heavy used (5 days weekly). each use will take about 30 minengine testing. At least 4 PhD and 2 MSc postgraduate to a few hours.students will be trained using this instrument.Potential users typically involve reseachers doing Heavy used (5 days weekly). Each test will take about up toengine testing. At least 4 PhD and 2 MSc postgraduate few hours.students will be trained using this instrument.589,800 341,400 248,400 589,800Hydrogen Refueling Station19 Dr Mahidzal Dahari 1 Supply Storage System 80,000 40,000 40,000 80,000 1 Malaysia Store hydrogen gasand Dispenser ControlSystems2 Dispensing System 40,000 20,000 20,000 40,000 1 Malaysia Deliver hydrogen gas3 Car Storage System 40,000 20,000 20,000 40,000 1 Malaysia Test and process hydrogen gas4 Recycling and Make-up40,000 20,000 20,000 40,000 1 Malaysia Recycle hydrogen gasSystem5 Data Acquisition System 40,000 20,000 20,000 40,000 1 Malaysia Collect experimental data6 Computer Control System 40,000 20,000 20,000 40,000 1 Malaysia Monitor and control hydrogen process7 Test-Rig Instrumentation60,000 30,000 30,000 60,000 1 Malaysia Other components (valves, fittings, piping) for completing fabricationSystem8 Fuel-Reforming System 60,000 30,000 30,000 60,000 1 Malaysia Produce and develop hydrogen gas9 Compressor System 40,000 20,000 20,000 40,000 1 Malaysia Compress hydrogen gas to higher pressure10 Flow-metering System 40,000 20,000 20,000 40,000 1 Malaysia Measure flowrate <strong>of</strong> hydrogen gasSince the development <strong>of</strong> a hydrogen refueling infrastructure is a critical element to theintroduction <strong>of</strong> fuel cell-powered vehicles, a flexible and low-cost hydrogen refueling test rigusing solar powered is proposed. It is flexible due to its ability to accept hydrogen from thethree available methods and easily be adapted to future renewable hydrogen productionsystem. The design is expected to be scalable for accommodating future growth which couldbe easily integrated to liquid hydrogen refueling with few modifications and minimalLab space is available in faculty <strong>of</strong> engineering (CADCAM department).additional investment. Along with all the built-in benefits <strong>of</strong> the station, innovative standardsand public awareness campaign are planned to encourage the acceptance <strong>of</strong> hydrogen as afuel, whilst supporting the national ongoing fuel cell-powered vehicle development program.With the operation <strong>of</strong> this facility to begin in 2011, it will be the first step in developing thecommercial hydrogen infrastructure <strong>of</strong> tomorrow, here in University Malaya.The research equipment is targeted to all level <strong>of</strong> The intensity and frequency <strong>of</strong> this equipment would be aresearchers in the world especially working on continuous usage for all researchers since thehydrogen economy since it covers a wide area <strong>of</strong> commercialization <strong>of</strong> gaseous hydrogen fueled vehiclesmultidisciplinary research fields. The contributions requires both the development <strong>of</strong> hydrogen fueled vehiclesfrom this research are expected to diversity into and the establishment <strong>of</strong> a hydrogen fueling infrastructure.following applications and technology areas;These requirements would create a circular cause and1) Hydrogen Fuel Reforming (efficiency study, consequence, that manufacturers will not build andturndown, compressor/purifier interface)consumers will not buy vehicles without an adequate2) Hydrogen Refueling Characterization (refining refueling infrastructure, whilst potential refueling stationthermodynamic model, refueling algorithm)operators will not invest the needed capital without an3) Hydrogen Dispensing Mechanism (component adequate market to serve. Therefore, the aims <strong>of</strong> this researchavailability & cost)are to achieve a hydrogen refueling system that wouldHydrogen Compressor (analytical design, tribology & breakthrough market requirements for cost-effectiveness,materials, empirical testing)reliability, and durability. It could discuss the fundamental4) Hydrogen Purification (assess adsorbent, membrane issues in term <strong>of</strong> energy consumption for producing hydrogenpurification strategies)based on renewable energy which subject to cost5) Hydrogen Station Design and Economics (system & expenditure, design analysis, safety, environmental issues,subsystem design and model, cascade storage and standards and public awareness. The approaches <strong>of</strong>integration system controls, economic model) developing the hydrogen refueling test rig could beAt least 5 PhD and 10 MSc students will be trained per elaborated into three main issues: how to mathematicallyPI from this project. This research will enable UM to develop and store the hydrogen gas, what testing facility iscreate niche area in hydrogen technology, which is needed to conduct the series <strong>of</strong> high pressure experiments;currently the latest technology is only available in US, and how to extract useful information for comparisons andEurope and Japan. UM hydrogen refueling test rig will verification <strong>of</strong> energy consumption.be the only state-<strong>of</strong>-the-art facility available to servefor ASIA countries (please refer to this website i.e.,www.fuelcellsworks.com)20 Dr. Andri Andriyana 1 Video Extensometer c/wAccessoriesTotal480,000 240,000 240,000 480,00090,000 - 90,000 190,000 - 90,0007,849,071 5,372,171 2,656,900 8,029,071 88Approved at the VM LABApproved at VM Lab-updated on 2nd March <strong>2012</strong> -