IQ plus 810 - Rice Lake Weighing Systems

IQ plus 810 - Rice Lake Weighing Systems

IQ plus 810 - Rice Lake Weighing Systems

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

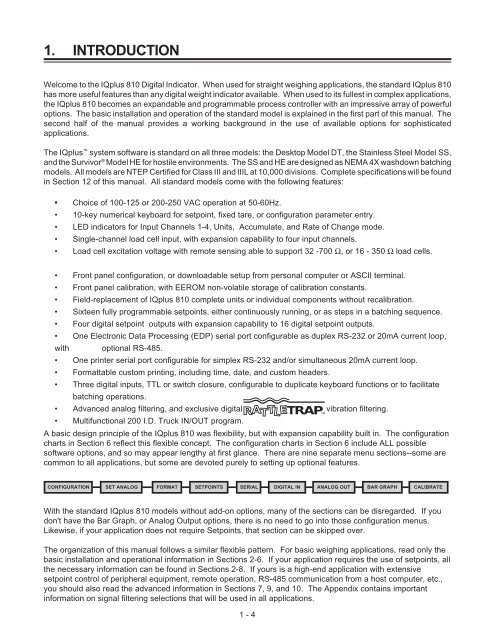

1. INTRODUCTIONWelcome to the <strong>IQ</strong><strong>plus</strong> <strong>810</strong> Digital Indicator. When used for straight weighing applications, the standard <strong>IQ</strong><strong>plus</strong> <strong>810</strong>has more useful features than any digital weight indicator available. When used to its fullest in complex applications,the <strong>IQ</strong><strong>plus</strong> <strong>810</strong> becomes an expandable and programmable process controller with an impressive array of powerfuloptions. The basic installation and operation of the standard model is explained in the first part of this manual. Thesecond half of the manual provides a working background in the use of available options for sophisticatedapplications.The <strong>IQ</strong><strong>plus</strong> system software is standard on all three models: the Desktop Model DT, the Stainless Steel Model SS,and the Survivor ® Model HE for hostile environments. The SS and HE are designed as NEMA 4X washdown batchingmodels. All models are NTEP Certified for Class III and IIIL at 10,000 divisions. Complete specifications will be foundin Section 12 of this manual. All standard models come with the following features:• Choice of 100-125 or 200-250 VAC operation at 50-60Hz.• 10-key numerical keyboard for setpoint, fixed tare, or configuration parameter entry.• LED indicators for Input Channels 1-4, Units, Accumulate, and Rate of Change mode.• Single-channel load cell input, with expansion capability to four input channels.• Load cell excitation voltage with remote sensing able to support 32 -700 Ω, or 16 - 350 Ω load cells.• Front panel configuration, or downloadable setup from personal computer or ASCII terminal.• Front panel calibration, with EEROM non-volatile storage of calibration constants.• Field-replacement of <strong>IQ</strong><strong>plus</strong> <strong>810</strong> complete units or individual components without recalibration.• Sixteen fully programmable setpoints, either continuously running, or as steps in a batching sequence.• Four digital setpoint outputs with expansion capability to 16 digital setpoint outputs.• One Electronic Data Processing (EDP) serial port configurable as duplex RS-232 or 20mA current loop,with optional RS-485.• One printer serial port configurable for simplex RS-232 and/or simultaneous 20mA current loop.• Formattable custom printing, including time, date, and custom headers.• Three digital inputs, TTL or switch closure, configurable to duplicate keyboard functions or to facilitatebatching operations.• Advanced analog filtering, and exclusive digital vibration filtering.RATTLETM TRAP• Multifunctional 200 I.D. Truck IN/OUT program.A basic design principle of the <strong>IQ</strong><strong>plus</strong> <strong>810</strong> was flexibility, but with expansion capability built in. The configurationcharts in Section 6 reflect this flexible concept. The configuration charts in Section 6 include ALL possiblesoftware options, and so may appear lengthy at first glance. There are nine separate menu sections--some arecommon to all applications, but some are devoted purely to setting up optional features.CONFIGURATIONSET ANALOGFORMATSETPOINTSSERIALDIGITAL IN ANALOG OUT BAR GRAPH CALIBRATEWith the standard <strong>IQ</strong><strong>plus</strong> <strong>810</strong> models without add-on options, many of the sections can be disregarded. If youdon't have the Bar Graph, or Analog Output options, there is no need to go into those configuration menus.Likewise, if your application does not require Setpoints, that section can be skipped over.The organization of this manual follows a similar flexible pattern. For basic weighing applications, read only thebasic installation and operational information in Sections 2-6. If your application requires the use of setpoints, allthe necessary information can be found in Sections 2-8. If yours is a high-end application with extensivesetpoint control of peripheral equipment, remote operation, RS-485 communication from a host computer, etc.,you should also read the advanced information in Sections 7, 9, and 10. The Appendix contains importantinformation on signal filtering selections that will be used in all applications.1 - 4