Tail Rotor Driveshaft Hanger

Tail Rotor Driveshaft Hanger

Tail Rotor Driveshaft Hanger

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

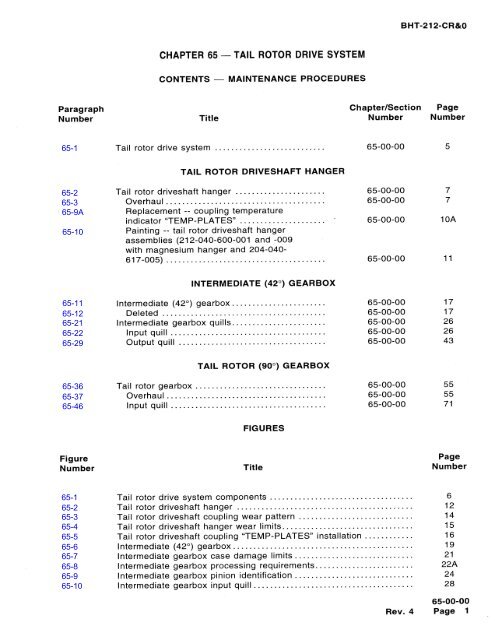

BHT-212-CR&0CHAPTER 65 - TAIL ROTOR DRIVE SYSTEMCONTENTS - MAINTENANCE PROCEDURESParagraphNumberTitleChapter/SectionNumberPageNumber65-1 <strong>Tail</strong> rotor drive system ........................... 65-00-00 5000 00TAIL ROTOR DRIVESHAFT HANGER65-2666 000<strong>Tail</strong> rotor driveshaft hanger ...................... 65-00-00 765-3 Overhaul ....................................... 65-00-00 765-9A Replacement -- coupling temperatureindicator "TEMP-PLATES" ..................... 65-00-00 10A65-10 Painting -- tail rotor driveshaft hangerassemblies (212-040-600-001 and -009with magnesium hanger and 204-040-=3'00 00000617-005) ....................................... 65-00-00 11INTERMEDIATE (42°) GEARBOX65-11Intermediate (42°) gearbox ....................... 65-00-00 17000006660000000000000000000065-12 Deleted ........................................ 65-00-00 1765-21 Intermediate gearbox quills ....................... 65-00-00 2665-22 Input quill ...................................... 65-00-00 2665-29 Output quill .................................... 65-00-00 43CA)TAIL ROTOR (90°) GEARBOX65-36 <strong>Tail</strong> rotor gearbox ................................ 65-00-00 5565-37 Overhaul ....................................... 65-00-00 5565-46 Input quill ...................................... 65-00-00 710)0)000000000'0^FIGURESFigurePageNumber Title Number65-1 <strong>Tail</strong> rotor drive system components ................................... 665-2 <strong>Tail</strong> rotor driveshaft hanger ........................................... 1265-3 <strong>Tail</strong> rotor driveshaft coupling wear pattern ............................ 1465-4 <strong>Tail</strong> rotor driveshaft hanger wear limits ................................ 1565-5 <strong>Tail</strong> rotor driveshaft coupling "TEMP-PLATES" installation ............ 1665-6 Intermediate (42°) gearbox ............................................ 1965-7 Intermediate gearbox case damage limits ............................. 2165-8 Intermediate gearbox processing requirements ........................ 22A65-9 Intermediate gearbox pinion identification ............................. 2465-10 Intermediate gearbox input quill ....................................... 280)0)0)0)0)0)0)0)0)0)(>) (L)3:O-_'(>) (L)((DDRev. 465-00-00Page 1

BHT-212-CR&0FIGURES (Cont)FigureNumberZ11TitlePageNumber65-11 Intermediate gearbox input quill wear limits ........................... 3265-12 Gear and pinion wear patterns ........................................ 3465-13 Quill coupling teeth wear patterns ..................................... 3765-14 Quill roller bearing wear pattern ....................................... 3865-15 Quill sleeve damage limits ............................................ 3965-16 DELETED ............................................................. 4265-17 Intermediate gearbox output quill ..................................... 45033m0000-0-65-18 Intermediate gearbox coupling wear pattern .......................... 4765-19 Intermediate gearbox output wear limits ............................... 4965-20 DELETED ............................................................. 5465-21 <strong>Tail</strong> rotor gearbox ..................................................... 5765-22 <strong>Tail</strong> rotor gearbox wear limits ......................................... 6165-23 Gear and pinion wear pattern ......................................... 6265-24 <strong>Tail</strong> rotor gearbox corrosion damage limits ............................ 6465-25 Roller bearing inspection .............................................. 6665-26 <strong>Tail</strong> rotor gearbox output shaft damage limits ......................... 6765-27 <strong>Tail</strong> rotor gearbox shims and studs dimensions ....................... 6865-28 <strong>Tail</strong> rotor gearbox input quill .......................................... 7365-29 <strong>Tail</strong> rotor gearbox input quill wear limits .............................. 7565-30 Input quill coupling teeth wear pattern ................................ 76C')TABLESTableNumberTitlePageNumber65-1 Magnetic particle inspection ........................................... 8065-00-00Page 2 Rev. 4

BHT-212-CR&0CONSUMABLE MATERIAL LISTThe following consumable materials are required to perform the maintenance procedures withinthis chapter.ITEMNO.NOMENCLATURECAGE/FSCM/SOURCEC-001 Grease, Aircraft General Purpose, MIL-G-81322 (AeroshellNo.22 or Mobil No.28)0 000 00mN(DEE-c.00m0ECommercialC-005 Lubricant, Solid Film, MIL-L-46010 Commercial00)0EE ECCOC-010 Lubricating Oil, Turbine Engine, MIL-L-7808 CommercialC-011 Lubricating Oil, Turbine Engine, MIL-L-23699 CommercialC-015 Lubricant (Tube Pack) 204-040-755-5 97499C-100 Chemical Film Material (Alodine 1200 or 1201) MIL-C-81706,Class 1A, Form 11 (Dip Tank) or III (Brush-on). Apply perMIL-C-5541.C-103 Chromic Acid (Brush-On Solution) Chromic Acid and CalciumSulfateCommercialCommercialC-105 Corrosion Preventive; Fingerprint Remover, MIL-C-15074 98308C-108 LHE Cadmium Plating Solution (For Brush Cadmium Plating) 13929C-112 Cadmium Chromate Conversion Coating Micro Bronze No. 1or 76071Enthox 280 or 02258Alumigold orNo. 6 CD orDalic 5005C-114 Corrosion Treatment (A mixture of items C-113, C-212 andwater or items C-115, C-212 and water)C-116 Chromic Acid (Technical), O-C-303-1 CommercialC-201 Zinc Chromate Primer, TT-P-1757 CommercialC-202 Epoxy (Super-Koropon) Primer 22873C-203 Acrylic Lacquer, MIL-L-81352. Refer to text for color. CommercialC-204 Epoxy Polyamide Primer, MIL-P-23377, MIL-P-85582, Type I.Refer to text for color.C-210 Epoxy Paint, White Catalyzed Color No. 17875 per FED-STD-595CommercialCommercialC-211 Shellac, TT-S-300, Type 1, Grade B, Body 2 CommercialC-298 Adhesive, Epoxy, Devcon 2-Ton CommercialC-304 Solvent, Drycleaning, P-D-680, Type 11, pH Insignificant CommercialC-305 Aliphatic Naphtha, TT-N-95, Type II Commercial65-00-00Rev. 4 Page 3

F5.BHT-212-CR&0CONSUMABLE MATERIAL LIST (Cont)ITEMNO.NOMENCLATURECAGE/FSCM/SOURCEC-308 Adhesive, Sealant, 299-947-107, Type III, Class 7, MIL-S- 974998802, Class B2 or 83527Proseal 890 835740(d2 T-5(n-C-309 Methyl -Ethyl-Ketone (MEK), TT-M-261 B, pH Insignificant Commercial(Alternate where MEK use prohibited: RHO SOLV 756) 83527CDVia)CCDC-317 Adhesive, Magnabond 6398 (299-947-100, Type II, Class 2) 22121 or97499C-318 Cleaning Compound, Alkaline Base, MIL-C-87936, pH Value12 Max. (Detergent) CommercialC-334 1.1.1-Trichloroethane, MIL-T-81533 (Vapor) or O-T-620(Cold)0)0000-INr0)CommercialC-405 Lockwire, MS20995C32 (0.032 Inch Dia.) CommercialC-407 Abrasive Pad, Nylon Web (Scotchbrite) L-P-0050, Type I, 27713 orClass 1, Size 1 76381C-409 Use C-500C-423 Abrasive Cloth (P-C-458) or Paper (P-P-101) (All Grits) CommercialC-427 Barrier Material, Greaseproofed and Waterproofed, Flexible,MIL-B-121CommercialC-432 Nitric Acid, O-N-350 CommercialC-434 Plating Tape, No. 420 26066C-436 Paint Remover, Alkaline Type, General, MIL-R-81294 or 80244MIL-R-8633A or 81349Turco No. 5469 61102C-464 India Stone, SS-S-736 CommercialC-490 Cork Stopper, LL-S-731, Type I, Grade A, Class 2 (Sizespecified in text)CommercialC-500 Crocus Cloth, Abrasive Coated, A-A-1206 CommercialCD CD CD65-00-00Page 4Rev.4

BHT-212-CR&OTAIL ROTOR DRIVE SYSTEM65-1. TAIL ROTOR DRIVE SYSTEM. (1), intermediate (42°) gearbox (2), and tailrotor (90°) gearbox (3).Principle components of the tail rotor drivesystem (figure 65-1) is the tail rotor driveshaft65-00-00Page 5

BHT-212-CR&O1. <strong>Tail</strong> rotor driveshaft2. Intermediate gearbox3. <strong>Tail</strong> rotor gearbox212-R-65-1Figure 65-1.<strong>Tail</strong> rotor drive system components65-00-00Page 6

BHT-212-CR&OTAIL ROTOR DRIVESHAFT HANGER65-2. TAIL ROTOR DRIVESHAFTHANGER.65-3. OVERHAUL.m65-4. Disassembly.NOTEIf hanger is being disassembled forreplacement of part(s), instead ofoverhaul, disassemble only to extentnecessary.1. Remove retainer ring (1, figure 65-2),plate (2), and spring (3) from outer coupling(8).2. Remove nut (16), washers (5), bolt (4),and retainer plate (6).65-5. Cleaning.NUMBERC-304C-436MATERIALS REQUIREDcowNOMENCLATURESolvent0Paint Remover1. Wash all parts, except bearings, withsolvent (C-304). Dry with filtered, compressedair.2. Clean bearing by wiping with dry, lint-freecloth. Do not allow bearings to spin whiledrying.3. Remove paint from hanger with paintremover (C-436). Rinse with clean water.N(a(CDNOTEFor ease of maintenance, blockouter coupling to remain in outboard(extended) position. This willstabilize outer coupling duringdisassembly and assembly.3. Slide rear coupling (15) from splined shaft(11). Remove inner and outer couplings (7and 8) from forward end of splined shaft.Remove seal (10) from outer coupling (8).3A. Observe condition of grease. If greaseis very viscous (thick) and has a strongpungent odor, replace outer coupling (8) andinner coupling (7).°`2°4. Support inner race of bearing (13) andpress out shaft (11).5. Remove retainer ring (12) and pressbearing from hanger (14).6. Discard bearing at overhaul.((DD3-O65-6. Conditional Inspection.000(Do0-oNOTEIf records or physical appearance ofhanger indicates component wassubjected to an accident or incidentoutside realm of normal usage,perform Conditional Inspection asfollows. If no evidence is found,accomplish Normal Inspection,paragraph 65-7.-`a?-`(n30:c1. Visually inspect curvic faces of outer andrear couplings (8 and 15, figure 65-2) fordistortion or evidence of overheating.lfoverheat conditions are noted, refer toparagraph 65-7.2. Visually inspect mounting ears of hanger(14) for cracks or distortion.3. Visually inspect teeth of spherical faces ofinner and outer couplings (7 and 8) for cracksor galling.(n04. Check bearing (13) for freedom andsmoothness of rotation.65-00-00Rev.3 Page 7I

BHT-212-CR&O5. Inspect detail parts for cracks bymagnetic particle or fluorescent penetrantmethods as applicable (paragraph 65-7)U)+-.0(BHT-ALL-SPM).(finNOTE,-.0If inspection reveals cracks ordistortion indicative of excessiveloads in any one detail part, entireassembly shall be consideredunserviceable and nonreparable.(OD06. Accomplish Normal Inspection (paragraph65-7).65-7. Normal Inspection.1. Visually inspect all parts for damage orexcessive wear.NOTEWear limits are provided to showrequired fit between mating parts. Itis not intended all dimensions bechecked as a prescribed overhaulprocedure. However, parts exhibitingevidence of wear or physicaldamage shall be checkeddimensionally.NOTEOvertemperature indicator dots ontemperature indicator TEMP-PLATES are of a white or light graycolor and turn black when exposedto an overtemperature condition.Chemical contamination can alsocause the indicating dots to turnblack.0(02.Q-2. Inspect inner coupling (7, figure 65-2) for 5. Inspect outer coupling (8, figure 62-5)acceptable wear patterns (figure 65-3). temp erature ind icator TEMP-PLATES (9) forevid ence of overtemperature indication. If3. Inspect following parts by magnetic overtemperatureindication is noted, performparticle (Code M) or fluorescent penetrant cou pling over temperature inspection as(Code F) (BHT-ALL-SPM), as applicable. follo ws:Demagnetize parts after magnetic inspection.a. Inspect outer coupling cadmium platingfor being discolored (circumferential tan orFigure, NomenclatureCodelight brown band) or blistered. If cadmiumIndex No.plate discoloration or blistering is found,replace outer coupling and inner coupling.(now0000000^a='¢;,65-2, 4 Bolt M65-2, 6 Retainer plate F65-2, 7 Inner coupling M65-2, 8 Outer coupling M65-2, 11 Shaft M65-2, 14 <strong>Hanger</strong> (see note) F/M65-2, 15 Rear coupling MNOTEPerform fluorescent penetrantinspection on magnesium hangers(14) and magnetic particle inspectionon steel hangers (14).4. Inspect parts dimensionally and replaceparts which exceed inspection limits (figure65-4).E.L-,(OD.(!)3.7a000-000b. Inspect gear teeth of outer couplingand inner coupling for being discolored(brown or blue) in the normally bright contactpatterns. If discoloration is found, replaceouter coupling and inner coupling.c. Inspect outer coupling and innercoupling under 5x to 10x magnification forteeth exhibiting signs. of metal smearing ortearing in the contact patterns. If smearing ortearing is found replace outer coupling andinner coupling.d. Inspect grease from couplings for beingvery viscous (thick) and having a strongpungent odor. If grease is found to be viscous(thick) and having a strong pungent odor,replace outer coupling and inner coupling.65-00-00Page 8 Rev. 3

BHT-212-CR&O,..:+3NOTEIf TEMP-PLATES are to be replaced,replace TEMP-PLATES aftercompleting entire inspection andrepair procedures and couplingshave been determined serviceableand prior to assembly.5A. Inspect outer coupling (8) temperatureindicator TEMP-PLATES (9) for deterioration,debonding or discoloration of epoxy coatingthat prevents interpretation of indicating dots.If deterioration, debonding, or discoloration ofepoxy is found, replace TEMP-PLATES inaccordance with paragraph 65-9A.-DI6. Inspect bearing (13) for evidence ofoverheating such as discoloration of bearing(blue to blue/black in color), multicolorappearance of hanger (14) which darkensadjacent to bearing. Any of the aboveconditions are cause to discard bearing.Brown color of bearing shield is normal and isnot evidence of overheating.con-00(D7. Hold bearing (13) outer race and turninner race by hand and simultaneously loadbearing by pressing axially on inner race.Obvious roughness, catching, or binding arecause to discard bearing.8. Deleted.9. Inspect hanger (14) for mechanical andcorrosion damage as follows:a. <strong>Hanger</strong> (14) is unserviceable andnonreparable if evidence of overheating isco.present.b. Inspect hanger for corrosion damage.Superficial corrosion damage is acceptable ifcorrosion is removed and hanger cadmiumplate is touched up.c. Inspect lubrication in bearing andhanger.((DDRev.365-00-00Page 8A/8B

BHT-212-CR&O10. Inspect inner coupling (7) for wear inarea contacted by seal (10). Rough surfaceand/or wear that would cause lubricantleakage is not acceptable.11. Inspect spring (3), bolt (4), retainer platet7)(CDM..(6), retainer rings (1 and 12), plate (2), andnut (16) for mechanical and corrosiondamage. Any damage which will affectfunction is not acceptable.65-8. Repair.NUMBERMATERIALS REQUIREDNOMENCLATUREC-108 Brush CadmiumPlating SolutionC-464 India StoneC-500 Crocus Cloth1. Replace all unserviceable parts and sealson assembly.2. Replace coupling seal (10, figure 65-2)and bearing (13) upon assembly.3. Dress splines of inner and outer couplings(7 and 8) with India stone (C-464), asnecessary, to blend out burrs, small nicks, orscratches.4. Polish nicks, burrs, or scratches onexterior surfaces with crocus cloth (C-500).5. Treat repaired cadmium plated surfaceswith brush cadmium plating solution (C-108)(BHT-ALL-SPM).65-9. Assembly.NUMBERcC-001C-015--IMATERIALS REQUIREDNN^1111-1NOMENCLATUREGrease...................? CAUTION ?Lubricant (Tube Pack)IF COUPLING SHAFT (11, FIGURE65-2), FORWARD INNERCOUPLING (7), OR REARCOUPLING (15) IS TO BEV-'mREPLACED, ENSURE MESHINGSPLINES HAVE 26 SPLINES ANDNOT 24 SPLINES.THE 212-040-602-1 AND -5S H A F T S A R E N O TINTERCHANGEABLE WITH 212-040-602-3 AND -7 SHAFTS. THE212-040-602-3 AND -7 SHAFTSARE LONGER AND HAVE ASMALLER OUTSIDE DIAMETER TOACCOMMODATE 204-040-623-3BEARING.1. Support inner race of bearing (13) andpress shaft (11) into bearing.NOTEBearing journal of shaft (11) must becentered on inner race of bearing(13) within 0.003 to 0.016 in. (0.0762to 0.4064 mm).2. Support hanger (14) and press bearingand shaft into hanger. Secure bearing withretainer ring (12).6. Replace parts which exceed allowablewear limits.7. Replace temperature indicator TEMP-PLATES if necessary. Refer to paragraph 65-9A.65-00-00Rev. 3 Page 9

BHT-212-CR&0(b-n--1 0-ca0)0ohm^mNOTEA workaid may be fabricated (figure65-2, detail B) to aid installation ofseal (10, figure 65-2).3. Install seal (10) into outer coupling (8)seal groove as follows:ate-O`4-poiU-0+0.,E0 0a. Apply a light coat of lubricant (tubepack) (C-015) to outer circumference of seal(10).b. Install seal (10) into outer coupling (8)seal groove with lip of seal toward internalsplines to outer coupling (8), as shown infigure 65-2, detail A.NOTESeal (10) will be partially seated andinner coupling (7) will be used as abackup, in reverse (see detail A) tofully seat outer circumference edgeof seal into outer coupling sealgroove.C. Using inner coupling (7) as a backupand placed (detail A), firmly press down (handQ-0pressure only) on outer coupling (8),simultaneously tuck outer circumference edgeof seal (10) with workaid into outer coupling(8) seal groove.d. Continue pressing around seal (10)with workaid until seal (10) is fully seated.Remove inner coupling (7) from outercoupling (8).4. Hand pack internal splines of outercoupling (8) with lubricant (tube pack) (C-015)...to 0.12 in. (3.048mm) deep over top ofinternal splines for full length of exposedsplines. A workaid may be fabricated (figure65-2, detail C) to obtain depth of grease.((DD=..0(ODU.)NOTEEnsure inner coupling (7) is correctfor tail rotor driveshaft hangercoupling, overall length is 2.07 to2.08 in. (52.578 to 52.832 mm).0-.,.-r4-0O+,0Coupling for 42° and 90° gearbox is1.87 to 1.88 in. (47.498 to 47.752mm) long.5. Install inner coupling (7), with small endthrough seal (10). Bottom out inner couplingagainst seal.6. Assemble retainer plate (6) and rearcoupling (15) onto splined end of inner shaft(11). Install inner and outer coupling (7 and8), retainer plate (6) on opposite end of innershaft (11). Install bolt (4) through retainerplate (6) with bolt head toward coupling end,with washers (5) and nut (16). Torque nut 50to 70 in.lbs. (5.649 to 7.9086 Nm) and securewith cotter pin.7. Place spring (3) onto alignment probe on Irear side of cover plate (2). Position springand cover on outer coupling (8), compressspring and install retainer ring (1). Ensureretainer ring is fully seated.NOTERefer to paragraph 65-10 forpainting of 212-040-600-001 and -009 tail rotor driveshaft hangerassemblies.°-.0)(D65-00-00Page 10Rev.4

BHT-212-CR&0NOTEIf hanger bearing (13) has beenreplaced during overhaul of hangerassembly and is new, do notlubricate bearing with a hand greasegun. The bearing has beenlubricated at the factory andadditional lubricant may damagebearing seal.8. Lubricate hanger bearing (13) with handgrease gun, using grease (C-001), Mobil 28only.1 9. The tail rotor hanger will be tagged withdate of lubrication and an entry made incomponent historical record, if hanger is to bereturned to stock.1 10. When tail rotor hanger is installed onhelicopter, an entry will be made in helicopterlog and flex couplings lubrication log.65-9A. REPLACEMENT - COUPLINGTEMPERATURE INDICATOR TEMP-PLATES.Dl.MATERIALS REQUIREDRefer to BHT-ALL-SPM for specification andsource.NUMBERNOMENCLATUREC-298 Epoxy AdhesiveC-309 Methyl -Ethyl- Ketone(MEK)C-318C-436Cleaning CompoundPaint Remover1. Remove epoxy coating and TEMP-PLATES using paint remover (C-436). Repeatprocess until no trace of epoxy is present..................CAUTION..................-pC+.N-0CONTAMINATION. ANYQ..0-0E0)°06-0CC)c2)--ICONTAMINATION COULD ALLOWTHE TEMP-PLATES TO COME OFFOR I N D I C A T E F A L S ETEMPERATURES.(Q0)LLs-.n30Q2)DAD2. Prepare outer coupling surface forbonding by scrubbing surface clean with acloth moistened with an authorized cleaner,such as MEK (C-309) to remove allcontamination. Before the cleaner solventdries, wipe the surface dry with a clean cloth.The cleaned surface should be at least 0.50m`"0X00inch (12.70 mm) larger than the TEMP-PLATES. Refer to figure 65-5 for location ofTEMP-PLATES on outer coupling.3. Accomplish a water break-free test onthe prepared bonding surface by applyingdistilled or demineralized water from asuitable, dispenser (such as a squeeze bottle).The water must flow into a continuous filmwithout gathering into distinct water dropletswithin 25 seconds after application on thesurface. Wipe dry with a clean cloth. Ensurethe bonding surfaces are not subsequentlycontaminated.4. If the coupling bonding surface will notmeet the water break-free test requirementsand the cleaning materials are notcontaminated, clean coupling bondingsurfaces as follows.NOTEFollow the manufacturersrecommendations for proper watermixtures.a. Using an authorized alkaline cleaningcompound (C-318) and cloth, scrub thecoupling bonding surface clear. Followcleaning with a thorough water rinse.b. Thoroughly dry coupling surfaces.C. Repeat water break-free test as statedabove.BONDING SURFACE AND TEMP-PLATES MUST BE FREE OF ALL65-00-00Rev.4 Page 1 0A

BHT-212-CR&O--{-gym2 CAUTIONIN ORDER TO PREVENTCONTAMINATION OF THE TEMP-PLATES ADHESIVE BACKING,ENSURE THAT WORK AREA ANDHANDS ARE THOROUGHLYCLEANED BEFORE WORKINGWITH TEMP-PLATES.DO NOT PRESS OR RUB THETEMP-PLATES WITH BAREFINGERS DURING INSTALLATIONON THE COUPLING AS THIS WILLCONTAMINATE THE SURFACES.APPLY EPOXY COATING TO THETEMP-PLATES IMMEDIATELYFOLLOWING INSTALLATION OFTHE TEMP-PLATES ONCOUPLING.m0m5. Carefully prebend the temperatureindicator TEMP-PLATES to match the Vcontour of coupling surface. Do not creasethe TEMP-PLATES sharply.NOTEWorking one TEMP-PLATE at atime, repeat steps 6 and 7 until allTEMP-PLATES are installed oncoupling.6. Remove protective backing from theTEMP-PLATE and carefully position onto thesurface prepared in step 2.7. Using a clean cloth or cotton swab, workthe TEMP-PLATE into the contour of thecoupling. A thoroughly cleaned firm rubber(edge of a block type eraser) workaid may beutilized to work TEMP-PLATE into full contactwith the coupling surface. Ensure the TEMP-PLATE is in full contact with the couplingsurface. Do not press or rub the TEMP-PLATE with bare fingers.m(t3-i.-0,NOTEUse of any epoxy adhesive otherthan Devcon 2-Ton is notauthorized.8. Prepare Devcon 2-Ton epoxy adhesiveepoxy adhesive (C-298) as follows:a. Pour equal amounts of epoxy Part Aand Part B into a solvent proof container.b. Vigorously mix Part A and Part B with abrush such as an artist brush.c. A few drops of authorized thinner, suchas MEK (C-309), may be added to the epoxyduring the mixing operation to reduce theviscosity to a level that permits uniform brushapplication of the epoxy mixture. Do not thinthis mixture such that it runs when applied toa vertical surface. The final viscosity of theepoxy should be similar to a heavily bodiedpaint. Too thin a mixture may seep into thetemperature indicator TEMP-PLATE andcause the indicator dots to turn black in whichevent, the TEMP-PLATE must be removedand replaced. Working time for the mixture isapproximately 15 minutes.D-109. Using a soft-bristled brush, uniformlyapply the epoxy coating over the TEMP-PLATES to a thickness of approximately0.002 to 0.004 inch (0.0508 to 0.1016 mm)similar to a coat of paint. The coating shouldbe uniform in appearance, totally cover thesurface of the TEMP-PLATES and extendapproximmately 0.25 inch (6.35 mm) beyondthe edges of the TEMP-PLATES.CAUTION 2DO NOT EXPOSE THE EPOXYCOATING TO OIL, GREASE,CLEANING SOLVENT OR OTHERCHEMICALS DURING CURE.c065-00-00Page 10BRev.3

BHT-212-CR&O10. Allow epoxy coating to cure at roomtemperature approximately 60 to 100°F (15.6to 38°C) for a minimum of six hours prior tohelicopter operation. For best results, allowepoxy to cure overnight prior to operatinghelicopter or exposure to oil or grease.0((DDtea)-,+o =":-CDNOTE0.." 0000An alternate source of heat can beused if the temperature does notexceed 180°F (82°C).(ate11. After one hour epoxy curing time atroom temperature, the epoxy coating totalcuring time can be accelerated by placing thecoupling in a temperature controlled oven forone to two hours at a temperature of 150 to180°F (66 to 82°C).12. Following the cure, the TEMP-PLATESshould conform to the contour of the couplingand be free of lifted edges. Indicating dots onTEMP-PLATES must remain the original whiteor light gray with no full or partial blackdiscoloration.13. Accomplish an adhesion test on eachTEMP-PLATE installation. Press a 1.00 inch(25.4 mm) wide strip of high adhesion tapeonto the TEMP-PLATE and epoxy overcoat.The tape should extend beyond the edge ofthe epoxy overcoat. Grasp one end of thetape at approximately 90 degrees from thesurface and remove tape in one abruptmotion. Lifting or peeling of the epoxy coatingor TEMP-PLATE is not acceptable. If lifting orpeeling is detected, remove and replaceTEMP-PLATE by repeating procedure..+J'07mo014. Repeat procedure for all tail rotor driveouter couplings.Q.-°O-(DD065-10. PAINTING - TAIL ROTORDRIVESHAFT HANGER ASSEMBLIES (212-040-600-001 AND -009 WITH MAGNESIUMHANGER AND 204-040-617-005).MATERIALS REQUIRED:_/p°)NUMBERC-204C-305m0-0MATERIALS REQUIRED (CONT)D^100+=O-0NOMENCLATUREPrimerAliphatic Naphtha1. Touch up exposed magnesium surfaceson hanger (14, figure 65-2) with chromic acid(C-103) (BHT-ALL-SPM).E oE2. Mask off bearing, seal, and couplings.Clean hanger in area to be painted with cleancheesecloth wetted with aliphatic naphtha (C-305). Wipe dry with clean cheesecloth beforenaphtha evaporates.3. Apply two spray coats of primer (C-204)0.4 to 0.9 mils (10.9 to 22.9 um) thickness.NOTEApply aluminized lacquer spray coatnot less than thirty minutes and notmore than eight hours, after epoxyprimer is applied.(ac4. Spray on first coat of aluminized, colorNo. 17178 lacquer (C-203) 0.4 to 0.6 milthickness. Allow to dry for thirty minutes toone hour and apply second coat.NOTEIf second coat of lacquer cannot beapplied within time limits noted in0(0 '-'step 5., second coat may be delayedfor up to seventy-two hours, butsurface to be painted shall becleaned with a tack rag prior toapplying second coat.5. Allow last coat of aluminized lacquer todry for forty-eight hours and remove maskingtape.6. Deleted.NUMBERC-103C-203NOMENCLATUREChromic AcidLacquer65-00-00Rev.3 Page 11

mI-:BHT-212-CR&O15INTERNAL SPLINESINNERCOUPLING(7)USEDASBACK-UPTOPUSHLIPOFSEAL00)UPSEAL(10)FULLYSEATEDOUTERCOUPLING(8)INSTALLEDINVERTEDONINNERCOUPLING16212-R-65-2-1Figure65-2.<strong>Tail</strong>rotordriveshafthanger(Sheet1of2)GREASEGROOVESIN204-040-623-003BEARING1.Retainerring9.Deleted2.Plate10.Seal3.Spring11.Shaft4.Bolt12.Retainerring5.Washer13.Bearing6.Retainerplate14.<strong>Hanger</strong>7.Innercoupling15.Rearcoupling8.Outercoupling16.NutNOTELocationofTemperatureindicatorTEMP-PLATE.65-00-00 Page12Rev.3

L}1.0 IN. 125.4 mm) RADIUS8 IN. (203.20 mm)--- 7.0 IN. 1177.80 mm)-2.0 IN.(50.8 mm)0.125 IN.(3.18 mm) 0.25 IN.L1.0 IN. (25.4 mm) (6.35 mm)BHT-212-CR&ONOTEQ2Make from plexiglass or similar material, remove all sharp edges.DETAIL B1.051N.(26.67 mm)0.27 IN. (6.80 mm)0.25 IN. (6.35 mm)771HANDLE LENGTH IS OPTIONAL0.1 IN.(2.54 mm)RADIUSU0.1201N.(3.05 mm)1_-I0.357 IN.f (9.53 mm)1.25 IN.(31.75 mm)COUPLINGTAIL ROTORDRIVESHAFT0.312 IN.(7.92 mm)Q3Make locally from 1 /4 in. (6.35 mm) plastic, or similar material.DETAIL C212-R-65-2-2Figure 65-2. <strong>Tail</strong> rotor driveshaft hanger (Sheet 2)65-00-00Page 13

BHT-212-CR&OA Acceptable pattern typical of low operatingtime.B Acceptable pattern typical of couplings whichhave operated with normal misalignment for alonger period of time than that shown in A.W//\\4C Acceptable pattern denoting operation athigher torque than that shown in A and B.+O+ +O+D Acceptable pattern showing a pitted tooth.This condition is acceptable on all teeth.=mmEPattern shows a more severe condition oftooth pitting than that shown in D. There isno metal projecting above the normal face ofthe tooth, indicating that the pitted area ispolishing over. This condition may exist on allteeth. Couplings with pits larger than 1/32Inch (0.79375 mm) diameter should be replaced.00000oooo65 3Figure 65-3.<strong>Tail</strong> rotor driveshaft coupling wear pattern65-00-00Page 14

BHT-212-CR&O7WMt mf ills a iI m,W0MIN.MAXITEM NOMENCLATURE INCHES mm INCHES mm(,)1 Outer Coupling - Internal Spline(Use 0.1309 IN. (3.32486 mm)Between pins 1.8290 46.4566 1.8360A 46.6344diameter pins)3DC 3C'-'C M'8CV)aC. pC.a)-2 Inner Coupling - External Spline(Use 0.1080 IN. (2.7432 mm)Over pins 2.1590 54.8386 2.1740 55.2196diameter pins)3 Inner Coupling and RearCoupling - Internal Splines(Use 0.0960 IN. (2.4384 mm)diameter pins)Between pins 1.1465 29.1211 1.1578 29.408124 Shaft - External Spline(Use 0.0960 IN. (2.4384 mm)Over pins 1.4424 36.63696 1.4465 36.7411diameter pins)5 Shaft - Bearing Seat(212-040-602-1 and 5) 1.3776 34.99104 1.3784 35.01136(212-040-602-3 and 7) 1.3476 34.22904 1.3484 34.249366 Bearing - Inner Diameter(204-040-623-1 and 5) 1.3775 34.9885 1.3781 35.00374(204-040-623-3) (Regreasable) 1.3477 34.23158 1.3481 34.2417400)LO..PLL)X007 Bearing - Outer Diameter 2.4403 61.98362 2.4409 61.998868 <strong>Hanger</strong> - Inner Diameter 2.4401 61.97854 2.4409 61.99886NOTEA Maximum depth of wear 0.005 inch (0.127 mm) measured from unworn face of tooth.Figure 65-4.<strong>Tail</strong> rotor driveshaft hanger wear limits212-R-65-465-00-00Page 15

BHT-212-CR&ON7 U----HANGER-204-040-604-005 COUPLINGREFr-i P-16000-1 TEMP-PLATE (RED BORDER)2 REQD-180 DEGREES APARTEQUALLY SPACED WITHIN 0.3 IN. (7.62 mm)IDENTIFICATIONPLATE0.74± 0.030 IN.(18.79±0.762 mm)212-R-65-5Figure 65-5.<strong>Tail</strong> rotor driveshaft coupling TEMP-PLATES installation65-00-00Page 16Rev.3

B HT-212-CR&0INTERMEDIATE (42°) GEARBOX65-11. INTERMEDIATE (42°) GEARBOX.65-12. DELETED65-13. Disassembly.NUMBERT1013080T101350SPECIAL TOOLS REQUIREDNOMENCLATUREJackscrewBacklash clampT102030-3 Backlash clamp204- 040- 001 -17 Puller tool (Sightglass)PAT-5Sor Equivalent2. Release pin (24) which secures chain tocase and remove cap (26). Remove packing(25) from cap. Discard packing.r:-.,-a)^N-03. Remove retainer ring (19), glass (21),and indicator (22). Use suitable tool toremove glass. Carefully remove packing (20)from glass. Discard packing.

BHT-212-CR&0I65-14. Cleaningmm300MATERIALS REQUIREDRefer to BHT-ALL-SPM for specification andsource.NUMBERC-010 Lubricating OilC-011 Lubricating OilNOMENCLATUREC-105 Corrosion PreventiveC-304 SolventC-436 Paint RemoverC-486 Cheesecloth1. Clean all parts with solvent (C-304).2. Dry parts with low pressure, filtered air orcheesecloth (C-486) Do not allow drybearings to spin.3. Remove sealant from gearbox case (6,figure 65-6) with plastic scraper.NOTEParts requiring fluorescent penetrantinspection shall be stripped of allfinishes.4. Remove all paint and primer fromgearbox case using paint remover (C-436).(°)(CDO'605. When parts are not to be usedimmediately after cleaning, gently agitateparts in corrosion preventive (C-105) and airdry. Apply protective coat of approvedlubricating oil (C-010) or lubricating oil (C-011).65-15. Conditional InspectionIfNOTErecords and/or physicalappearance of gearbox indicateassembly has been subjected to anaccident or incident outside realm ofr-0normal usage, perform ConditionalInspection as follows. If gearboxdoes not require ConditionalInspection, accomplish NormalInspection (paragraph 65-16).1. Inspect gearbox and gearbox records todetermine whether gearbox has beensubjected to an accident or incident outsidethe realm of normal usage which would=30require conditional inspection. Refer to BHT-(DD:.,212-MM, for definition of accidents orincidents which require that conditionalinspection be conducted..-.(NDD))E-i.2. If conditional inspection is not required,proceed with normal inspection, paragraph65-16.0°:3o-c1-03. Check gearbox for free rotation andbacklash of gears. Backlash should not varymore than 0.002 inch (0.0508 mm), whenchecked at different points around gear.4. Perform fluorescent penetrant inspectionof gearbox case (16, figure 65-6) (BHT-ALL-SPM).NOTEIf inspection reveals cracks ordistortion, gearbox shall beconsidered unserviceable andnonrepairable.5. Accomplish Normal Inspection,paragraph 65-16.65-16. Normal Inspection1. Inspect gearbox case (6, figure 65-6) fordamage which would cause it to benonserviceable or nonreparable.2. Inspect studs and washer seats (9 and 8)for looseness, damage, and corrosion.3. Inspect gearbox case quill ports for4.4100 to 4.415 inches (112.014 to 112.141mm) inside diameter.4. Inspect oil filler cap (26, figure 65-6) andadapter (23) for damage and wear.65-00-00Page 18Rev.4a))

BHT-212-CR&05. Inspect oil level sight glass (21) forcracks, crazing, scratches, or discoloration.Inspect indicator (22) for stained or peeledpaint.6. Inspect chip detector (17) for obviousdamage.7. Inspect gearbox case for corrosion andfor elongated mounting bolt holes (figure 65-7).8. Perform fluorescent penetrant inspectionof gearbox case (BHT-ALL-SPM).9. Inspect shim plate (10, figure 65-6) fordamage and wear.(Do0.0--l-6NOTEIf inspection reveals cracks ordistortion, gearbox case shall beconsidered unserviceable andnonrepairable.10. Inspect chip detector (17) for obviousdamage.NOTEr«00Overtemperature indicator dots ontemperature indicator "TEMP-PLATES" are of a white or light graycolor and turn black when exposedto an overtemperature condition.Chemical contamination can alsocause the indicating dots to turnblack.Imo11. Inspect outer couplings (13 and 28)temperature indicator "TEMP-PLATES" orevidence of overtemperature indication. Ifovertemperature indication is noted, performcoupling overtemperature inspection asfollows:L(0(LOa. Inspect outer coupling cadmium platingfor being discolored (circumferential tan orlight brown band) or blistered. If cadmiumplate discoloration or blistering is found,replace outer coupling and inner coupling.-(p0_a-DO4-+O.-Q'-ac-00i'-'"'U,_3(Qb. Inspect gear teeth of outer couplingand inner coupling for being discolored(brown or blue) in the normally bright contactpatterns. If discoloration is found, replaceouter coupling and inner coupling.C. Inspect outer coupling and innercoupling under 5x to 10x magnification forteeth exhibiting signs of metal smearing ortearing in the contact patterns. If smearing ortearing is found, replace outer coupling andinner coupling.d. Inspect grease from couplings forbeing very viscous (thick) and having a strongpungent odor. If grease is found to be viscous(thick) and having a strong pungent odor,replace outer coupling and inner coupling.NOTEIf "TEMP-PLATES" are to bereplaced, replace "TEMP-PLATES"after completing entire inspectionand procedures and couplings havebeen determined serviceable andprior to assembly.12. Inspect outer couplings (13 and 28)temperature indicator "TEMP-PLATES" fordeterioration, debonding or discoloration ofepoxy coating that prevents interpretation ofindicating dots. If deterioration, debonding, ordiscoloration of epoxy is found, replace"TEMP-PLATES" in accordance withparagraph 65-9A.poi65-00-00Rev.4 Page 18A/1813

BHT-212-CR&O1. Output quill2. Nut3. Washer (2)4. Shim plate5. Screw6. Case7. Data plate8. Washer seat9. Stud10. Shim plate1 1 . Screw12. Packing13. Coupling14. Nut15. Washer (2)16. Input quill17. Chip detector18. Packing19. Ring20. Packing21. Glass22. Indicator23. Oil filler adapter24. Pin25. Packing26. Cap27. Chain28. Coupling006a0+ O=_,4;19151410NOTEQ Location of temperature indicator TEMP-PLATES.13212-R-65-6Figure 65-6.Intermediate (42°) gearbox65-00-00Rev.3 Page 19

BHT-212-CR&065-17. Repaircoo...La=`goo'-o3EECADE-0MATERIALS REQUIREDRefer to BHT-ALL-SPM for specification andsource.NUMBERC-100C-105C-108C-112C-116C-204C-308C-423C-432C-494CJ)cc-0U)ENOMENCLATUREChemical Film MaterialCorrosion PreventiveBrush CadmiumPlating SolutionCadmium ChromateConversion Coating00Chromic AcidPrimerAdhesiveAbrasive cloth orPaperNitric AcidInkNOTEReplace case if structural damage tostud threads or mounting bolt holesare elongated so repair limits areexceeded.1. Replace parts which exceed allowablewear limits.2. Repair corrosion damage on the case asfollows (figure 65-7):a. Flange repair: Machine off upper faceto a minimum flange thickness of 0.40 inch(10.16 mm) (dimension B, figure 65-7)provided this leaves no pits in excess of0.010 inch (0.254 mm) deep and affectedarea does not exceed inspection limits.Rework case using a 0.875 inch (22.225 mm)...momfro3.213.00diameter spotface with 0.062 inch (1.5748mm) corner radius. Machined surface finishshall be 63 RMS or better.65-00-00Page 20Rev.4b. Stud hole damage: Remove damagedor loose studs. Use suitable tool to grip studand turn out slowly and evenly to avoidseizure and breakage. If stud hole threads aredamaged, repair or replace case as required.a0-5 -"`con'-"cc.,-«4+,aS11C70If corrosion or other damage has notpenetrated past first thread,follows (BHT-ALL-SPM):D.c((DD33.rework case as(1) Machine or drill out damagedthread. Do not exceed depth of one thread.2.3Clean out diameter shall equal major threaddiameter.(2) Break all sharp edges, except inarea of threads. Clean out small vent hole inbottom of threaded hole. Treat bare surfaceswith chemical film material (C-100).(3) Replace stud (BHT-ALL-SPM).(4). Fill all counterdrilled holes withadhesive (C-308) flush with top of case.c. Repair minor scratches, nicks, and pitson noncritical surfaces with abrasive cloth orpaper (C-423).d. Cases with corrosion damage withinacceptable limits must be treated byimmersion in a hot chromic acid bathconsisting of 20 to 24 ounces (591.4 to709.68 ml) of chromic acid (C-116) per gallon(/j3-t3-firc>,=r,

BHT-212-CR&0Required dimensions shall be met afterplating (BHT-ALL-SPM).b. If original shim plate is missing ormixed with other shim plates, determinerequired dimensions of replacement shimplate as follows:(1) Examine case for referencedimension which is metal stamped or vibro-,-.etched on part adjacent to applicablemounting surface.(2) Subtract dimension etched orstamped on case from 3.4670 to 3.4675inches (88.0618 to 88.0745 mm) to giveTWOc°E`(flrequired shim thickness, after plating.Rev.465-00-00Page 20A/20B

BHT-212-CR&0SIDE VIEWVIEW LOOKING AFT0.290 IN.17.366 mm)MAXIMUM ACCEPTABLEELONGATION OFMOUNTING BOLT HOLESNOTES1. Corrosion pitting on upper machined face at four mounting bolt holes is acceptable provided it is nomore 0.020 inch (0.508 mm) deep, no more than 20 percent of total area is pitted, no more than 10percent of the area under washer is pitted and minimum thickness of flange in pitted area is no less than0.430 inch (10.992 mm).2. Cases having damage exceeding inspection limits may be reworked by machining off upper face to aminimum flange thickness of 0.400 inch (10.16 mm) (see dimension B above) provided this leaves nopits in excess of 0.010 inch (0.254 mm) deep and affected area does not exceed limits given above.CI)3. Rework case using a 0.875 inch (22.225 mm) diameter spot face with 0.062 inch (1.5748 mm) cornerradius. Machined surface finish must be 63 RMS or better.°)yCSI4. Corrosion pitting in area A is acceptable provided it is no more than 0.030 inch (0.762 mm) deep and nomore than forty percent of area within any one inch square (25.4 square mm) nor twenty percent oftotal area A at either bore is pitted. Structural damage to threaded holes for studs is acceptableprovided damage does not extend past first thread.a..coo=E°-'Figure 65-7. Intermediate gearbox case damage limits (Sheet 1 of 2),C+212-R-65-7-1i65-00-00Rev.4 Page 21

BHT-212-CR&O.w.212-040-506-1 CASE ASSYAREAS OF ACCEPTABLE CORROSION PITTING ON LOWER SURFACESOF CASE MOUNTING PADS DIMENSIONAL LIMITS APPLY TO AFFECTEDAREAS AFTER CORROSION HAS BEEN POLISHED OUT.-DrFOR -1 CASE ASSY MADEFROM -15 MACHINING0.25 IN. (6.35 mm) TYP0.28 IN. (7.11 mm) R MIN TYP(fltri==O30,-0..L.FOR -1 CASE ASSY MADEFROM -3 OR -9 MACHINING>-:E00:E EBOTTOM VIEWMaximum depth of acceptable corrosion pitting is 0.015 inch (0.381 mm)measured from machined surface of mount pad after all pitting has beenpolished out.Maximum depth of acceptable corrosion pitting is 0.030 inch (0.762 mm)measured from machined surface of mount pad after all pitting has beenpolished out.NOTES1. Corrosion pitting on either pad may extend over no more than 50% ofany one square inch of area in which pitting is allowed or, as anaggregate total, cover more than 30% of the area.2. Polish out corrosion pitting removing minimum material to produce asurface finish of 63 microinches or better. Fillet radii to be 0.125 inch(3.175 mm) minimum.3. Cases with corrosion damage within acceptable limits must be treatedby immersion in chromic acid bath in accordance with instructions givenin BHT-ALL-SPM for magnesium parts to remove all corrosion products.4. Chemical film treat corroded areas in accordance with BHT-ALL-SPMfor magnesium parts.+L+....O.f/)G))5. Apply (2) coats of MIL-P-23377 polyamide epoxy primer in accordancewith instructions given in BHT-ALL-SPM.Figure 65-7. Intermediate gearbox case damage limits (Sheet 2)212-R-65-7-265-00-00Page 22Rev.4

BHT-212-CR&0=010,0AMP-0-ININNER COUPLING204-040-603OUTER COUPLING204-040-604SLEEVE212-040-502VIEW AI/VIEW BCASE212-040-506NOTESCadmium plate will be applied to this area only.Q Do not apply cadmium plate in hole.Q Epoxy primer and acrylic lacquer will be applied to this area only.Q Primer and final finish will not be applied to this area.212-R-65-8Figure 65-8. Intermediate gearbox processing requirements65-00-00Rev.4 Page 22A/226

BHT-212-CR&0(3) Grind new blank shim to requiredthickness and apply brush cadmium platingsolution (C-108). Using ink (C-494) orequivalent, identify new shim plate by etchingserial number of applicable case on shimplate. Also etch thickness on shim plate.Neutralize etching ink with water and commonbaking soda after etching.-0_D))cad--aCo.:a)==c-0EJ-2 :-°5. Repair oil filler cap as required (BHT-212-MM).6. Replace oil level sight glass (21), ifcracked, crazed, scratched, or discolored andreplace indicator (22), if stained or if paint ispeeled (BHT-212-MM).7. All parts repaired shall be reinspectedprior to use. Replace all parts which arecracked, broken, warped, distorted, havemalformed threads, or which cannot berepaired. Replace all seals, gaskets,packings, standard hardware, and all lockingdevices, on reassembly.8. Apply brush brush cadmium platingsolution (C-108) and chemical film material(C-100) to required areas of parts from whichfinish was removed during inspection andrepair (BHT-ALL-SPM).033-o9. Apply supplementary chromateconversion coating, on cadmium plated parts,by swabbing or brushing for 30 seconds(maximum). Refer to BHT-ALL-SPM.10. Replace coupling "TEMP-PLATES" ifnecessary (Paragraph 65-9A).65-18. AssemblyMATERIALS REQUIREDRefer to BHT-ALL-SPM for specification andsource.0_-0zNUMBERMATERIALS REQUIRED (CONT)0fatw-wc0NOMENCLATUREC-423 Abrasive Cloth orPaper1. Position original shim plates (4 and 10,figure 65-6) or replacement shim plates oncase (6). Install each shim plate with threescrews (5 and 11).0-.(CD(D38+,2. Use heat lamp at each input and outputport to heat gearbox case (6).NOTETeeth of pinion on input quill andoutput quill are cut opposite eachother (figure 65-9).3-Q3. Place packing (12, figure 65-6) on sleeveof each quill. Coat packing and matingsurfaces of quill sleeves and gearcase withgearbox oil. Insert input quill (16) in forwardport.NOTEOnly the output quill has an oilcollector cone.4. Install washers (15) and nuts (14) onstuds and tighten evenly. Ensure onlyaluminum washers (3) and (15) are in contactwith quill sleeve. Torque 50 to 70 inch-lbs.(5.649 to 7.9086 Nm).5. Install output quill (1) in same mannerusing washers (3) and nuts (2). Exercise careto engage gear and pinion teeth wheninstalling second quill to avoid damage.NOTENUMBERNOMENCLATURECheck backlash and torque checkC-305 Aliphatic Naphthanuts (2 and 14) when gearboxC-309 Methyl-Ethyl-Ketone stabilizes at room temperature.(MEK)C-317 Adhesive65-00-00Rev.4 Page 23(DD

BHT-212-CR&06. Check for backlash using T101350 clampand T102030-3 clamp. Take reading from0D) 00m3J3'.-(l)'00pp)p))3-00:IC)1-'Nmoocenter of dowel pin in T102030 clamp (pinlocation is marked 212). Backlash 0.004 to0.010 inch (0.1016 to 0.254 mm). Check inthree places approximately 120 ° apart,record readings. In any one assembly,backlash reading shall not vary more than0.002 in. (0.0508 mm) when checked at threeplaces around gear. A greater variationindicates a warped gear. Check gears andreject out of tolerance parts.CAUTIONDO NOT ALTER SHIM PLATES ONCASE OR QUILL SLEEVES TOOBTAIN BACKLASH. IF BACKLASHIS NOT WITHIN LIMITS, PARTS01-ARE IMPROPERLY ASSEMBLED,OR ARE DIMENSIONALLYINCORRECT.NOTEHalf-inch (12.7 mm) diameter whitedot on cap (26) and on case (6)locoart ^-Ddenotes vented cap shall be'+3installed.7. Lubricate packing (25) with gearbox oiland install on cap (26) and install oil filleradapter (23). Secure chain (27) to case withpin (24).a..Deleted:00)00°aNOTE8. Lubricate and install packing (20) onsight glass (21) and lubricate with gearbox oil.Position indicator plate (22) in case with tangin notch. Install glass (21) with recessed sideinboard. Install ring (19).,.m 0°39. Place gasket (18) on chip detector (17)and install in case. Torque 120 to 150 inch-Ibs. (13.5576 to 16.947 Nm).NOTE300Chip detector will be secured toadjacent mounting bolthead whengearbox is installed on helicopter.3'-l212-R-65-9INPUTOUTPUT65-00-00Page 24Rev.4Figure 67-9. Intermediate gearbox pinion identification

BHT-212-CR&010. Prepare data plate (7) for installation..+n(1)a:..................CAUTIONSTAMPING DIRECTLY ONSURFACE OF INSTALLED DATAPLATE IS PROHIBITED.a. Data plate information shall includeinitials of facility performing overhaul or((DDmodification, date of overhaul ora0-modifications, and part number. Totaloperating time since new shall be included, ifapplicable. Stamp date of overhaul ormodification in area adjacent toc-0HC( U-0D))tea)--I((fa>0.,3o`

f(DBHT-212-CR&02. Fill groove between case and quillsleeves and around bearing retaining nutswith adhesive (C-308). Allow to cure for 72hours at room temperature.3. Remove oil filler cap. Mask filler capadapter, chip detector, oil level sight glass,couplings, and seals at outboard ends ofquills, and data plate.4. Spray paint gearbox with primer (C-246),coat 0.4 to 0.9 mil thickness.caln(DNOTEApply coating of coating (C-245), asp e r m a n u f a c t u r i n grecommendations, not less thanthirty minutes and not more thanfour hours after epoxy primer isapplied.5. DeletedDeleted6. DeletedNOTE7. Use brush to apply 1/2 inch (12.7 mm)diameter dot of white catalyzed epoxy paint(C-210) to oil cap and to gearbox case. Doton case should be placed on boss below oilcap adapter and directly above chip detector.65-20. Run-in and test.It is recommended that intermediate gearbox,after overhaul, be test run, and inspected inaccordance with Bell Helicopter Textron BHT-PUB-77-003, Run-in and Test Manual that isfurnished with run-in test stand. In the event arun-in stand not available, the functional test02).-ri1)D=+Cam'itsteaspecified in BHT-212-MM, may beaccomplished as minimum acceptablealternate test.65-21. INTERMEDIATE GEARBOX QUILLS''° ^°^p``LCDC1- C13(MO(On.-r(

cBHT-212-CR&02. Hold outer coupling (11) with T101307wrench; position square adapter throughwrench and remove coupling retaining bolt(2). Remove washer (1).I-°I--=.30(QOD-3. Remove couplings (10 and 11) frompinion (25).4. Separate couplings (10 and 11) andremove seal (14) from coupling (11).5. Position T101564 holding fixture onsleeve (18) with T101600 wrench, positionedon nut (15). Remove nut (15). Removepacking (16) and press seal (14) out of, nut.Discard packing and seal.6. Press pinion (25) out of sleeve (18).Remove retaining ring (26) and roller bearing(27) using T101333 pressing bar. Pressduplex ball bearing (17) out of sleeve usingT101334 pressing bar.NOTEEL.4Non'Duplex bearings are a matched set,both bearings have same serialnumber. Keep duplex bearingstogether as a set.Cu)4U) E7. Input quill 212-040-003-009, removeretainer ring (22) and plug (23) from pinion(25). Remove packing (24).D))3.o8. Remove three screws (21) and shimplate (20). Identify shim plate for installationon same sleeve..65-24. CleaningMATERIALS REQUIREDRefer to BHT-ALL-SPM for specification andsource.NUMBERNOMENCLATUREC-105 Corrosion PreventiveC-304 SolventC-334 1.1.1-TrichloroethaneC-436 Paint Remover1. Clean quill parts with solvent (C-304)with exception of bearings which are cleanedwith 1.1.1-trichloroethane (C-334).C3)-(aAte)0Ac)0`G A)`

BHT-212-CR&ONOTESLocation of temperature indicator TEMP-PLATE.Apply adhesive sealant (C-308) on nut 0 5) andsleeve 08) after assembly.Useable on input quill 212-040-003-009.1. Washer 8. Plate 15. Nut [\ 22. Retainer ring2. Retaining bolt 9. Retainer ring 16. Packing 23. Plug3. Packing 10. Inner coupling 17. Duplex ball bearing 24. Packing4. Retainer 11. Outer coupling 18. Sleeve25. Pinion5. Spacer 1 2 . Deleted 19. Clinch nut226. Retaining r ing6. Lock spring 13. Seal 20. Shim plate 27. Roller bearing7 . Centering spring 14 . Seal 21 . Screw212-R-65-10-1Figure 65-10. Intermediate gearbox input quill (sheet 1 of 2)01.65-00-00Page 28Rev.4

BHT-212-CR&0SEAL (13) PARTIALLY SEATEDINTERNALSPLINES-INNER COUPLING (10) USEDAS BACK-UP TO PUSH LIPOF SEAL (13) UPOUTER COUPLING (11)INSTALLEDINVERTED ON INNERCOUPLINGSEAL (13) FULLY SEATEDDETAIL A0.818 ---INCH(20.777 mm)DETAIL B204.040-607-7SPRING RETAINERFOR INPUT QUILLDETAIL C204-040-607-5SPRING RETAINERFOR OUTPUT QUILL212-R-65-10-2Figure 65-10. Intermediate gearbox input quill (sheet 2)..sa-.65-00-00Rev.4 Page 29

BHT-212-CR&0blow or pressure or rollers skidding instead ofrolling.0O)-a.E05. Perform magnetic particle inspection ofpinion (25) and couplings (10 and 11) (BHT-ALL-SPM).O(76. Perform fluorescent penetrant inspectionof sleeve (18) (BHT-ALL-SPM).(DD0cause the indicating dots to turnblack.4. Inspect outer coupling (11, figure 65-10)temperature indicator "TEMP-PLATES" forevidence of overtemperature indication. Ifovertemperature indication is noted, performc00C),0coupling overtemperature inspection asfollows:@')a.NOTEInspect outer coupling cadmium platingfor being discolored (circumferential tan orlight brown band) or blistered .If steps 1. through 5. reveal cracks If cadmiumor distortion indicative of excessive plate discoloration or blistering is found,loads, quill shall be considered replace outer coupling and inner coupling.unserviceable and nonreparable.b. Inspect gear teeth of outer coupling(OD0-tix?'7. Accomplish Normal Inspection(paragraph 65-26).65-26. Normal Inspection001. Inspect parts dimensionally and replaceparts that do not fall within inspection limits(figure 65-11).NOTEWear limits are provided to showrequired fit between mating parts. Itis not intended all dimensions bechecked as prescribed overhaulprocedure. However, parts exhibitingevidence of wear or physicaldamage shall be checkeddimensionally.2. Inspect pinion (25, figure 65-10) splinesfor chipped, broken or worn teeth.3. Inspect pinion (25) teeth for excessivewear, scoring, scuffing, and wear pattern(figure 65-12).NOTEOvertemperature indicator dots ontemperature indicator "TEMP-PLATES" are of a white or light graycolor and turn black when exposedto an overtemperature condition.Chemical contamination can also' 65-00-00Page 30 Rev.4(Q`L^0 ()= 0°a0^(n-:3or'X(cc(Q0a`.Land inner coupling for being discolored03.0a=) a°0c(brown or blue) in the normally bright contactpatterns. If discoloration is found, replaceouter coupling and inner coupling.C. Inspect outer coupling and innercoupling under 5x to 10x magnification forteeth exhibiting signs of metal smearing ortearing in the contact patterns. If smearing or0)O)0tearing is found, replace outer coupling andinner coupling.d. Inspect grease from couplings forbeing very viscous (thick) and having a strongpungent odor. If grease is found to be viscous(thick) and having a strong pungent odor,replace outer coupling and inner coupling.NOTEIf TEMP-PLATES are to be replaced,replace "TEMP-PLATES "aftercompleting entire inspection andrepair procedures and couplingshave been determined serviceableand prior to assembly.4A. Inspect outer coupling (11) temperatureindicator "TEMP-PLATES" for deterioration,debonding or discoloration of epoxy coatingthat prevents interpretation of indicating dots.If deterioration, debonding, or discoloration ofepoxy is found, replace "TEMP-PLATES" inaccordance with paragraph 65-9A.5. Inspect couplings (10 and 11).5.0

BHT-212-CR&0000000)0)0)1a. Inspect for chipped, pitted, cracked, orexcessively worn teeth.b. Check wear patterns (figure 65-13).C. Inspect surface of inner couplingscontacted by seals (14, figure 65-10) forexcessive wear, nicks, and scratches. Ac0001 0-0...O()groove worn by seal is acceptable to afl.000minimum diameter of 1.587 inch (40.3098mm) provided depth does not exceed 0.002inch (0.0508 mm). If groove is smooth, partmay be reworked.6. Inspect following parts by magneticparticle (Code M) or fluorescent penetrant(Code F) (BHT-ALL-SPM), as applicable.Demagnetize parts after magnetic particleinspection.Figure,Index No.NomenclatureCode65-10, 10 Inner coupling M65-10, 11 Outer coupling M65-10,25 Pinion M65-10, 2 Bolt M65-10, 4 Retainer F65-10, 8 PlateF65-10, 15 Nut F65-10, 18 Sleeve F8. Inspect bearing liners for scoring andsecurity of mounting in sleeve (18).15L3--W-0:3:9. Inspect bearings for spalling, scoring,pitting, brinelling, flaking, corrosion on rollingelements, and cracked or broken retainers(figure 65-14).a. Minor nicks, cuts, or scratches areacceptable provided they are too small to befelt with a probe having an end radius of0.030 inch (0.762 mm), and provided totalaffected area does not exceed 10% of contactarea at any point.QC)b. Minor circumferential scoring isacceptable on rollers and races provided itcannot be felt with a probe having an endradius of 0.030 inch (0.762 mm) and providedaffected area does not exceed 10% of contactarea at any point.3'mS1)O.310. Inspect sleeve (18, figure 65-10) forcorrosion damage (figure 65-15).011. Perform fluorescent penetrantinspection of sleeve (BHT-ALL-SPM).12. Inspect shim plate (20, figure 65-10) fordamage and wear.7. Check bearings (17 and 27) for smoothoperation and indications of excessive wear.Inspect bearing races for roughness.65-00-00Rev.4 Page 30A/3013

BHT-212-CR&013. Inspect plate (8) for damage seal.00))014. Inspect coupling retaining bolt (2)visually for damaged threads. Replace boltswhich have malformed threads.au,"3Q15. Inspect nut (15) visually for damagedthreads. Replace nuts which have malformedthreads.65-27. RepairMATERIALS REQUIREDRefer to BHT-ALL-SPM for specification andsource.NUMBERNOMENCLATUREC-100 Chemical Film MaterialC-103 Chromic AcidC-108 Brush CadmiumPlating SolutionC-201 PrimerC-309 Methyl- Ethyl- Ketone(MEK)C-317 AdhesiveC-334 1.1.1-TrichloroethaneC-423 Abrasvie Cloth orPaperC-434 TapeC-464 India StoneC-500 Crocus Cloth01. Replace parts which exceed allowablewear limits.2. Replace bearings (17 and 27, figure 65-10) exhibiting evidence of brinelling, spalling,discoloration from overheating, corrosion onrolling elements, cracked or broken retainers,or rough operation.3. Replace all seals, packings, standardhardware, and all locking devices at time ofreassembly.(L).Fn4. Repair minor scratches, nicks, and pitson noncritical surfaces with abrasive cloth or Ipaper (C-423).3-'. x'03-0EE(/)F-3_3m(ODCOD5. Repair minor nicks, scratches, and burrson splines and pinion (25) using India stone(C-464).6. Repair inner coupling (10) and outercoupling (11) as follows:0L()00a. Repair minor nicks, dents, or scratchesin seal contact area on inner couplings bypolishing with India stone (C-464) to removedamage. Blend into surrounding area. Sealgroove wear no more than 0.002 inch (5.08mm) deep and minimum diameter of 1.587inch (40.3098 mm) is acceptable if groove isuniform and smooth. More severe damage inseal contact area may be reworked bygrinding, provided it gives 100% cleanup,when reworked as directed below.b. Grind coupling OD to a minimumdiameter of 1.587 inches (40.3098 mm).Reground diameter shall not extend morethan 0.40 inch (10.16 mm) from inner end ofcoupling and blend with original surface.C. Reground diameter shall be concentricwith pitch diameter of internal spline within0.002 inch (0.0508 mm) TIR.d. Surface finish on reground diametershall be 16 RMS or better.e. Nital etch couplings after grinding(BHT-ALL-SPM).f. Inspect couplings after vital etchprocess by magnetic particle method. Refer toBHT-ALL-SPM.g. Touch-up cadmium plate couplings (10and 11, figure 65-10) using brush cadmiumplating solution (C-108). Plating thickness tobe 0.0001 to 0.0003 inch (0.00254 to 0.00762mm). Do not exceed 0.0003 inch (0.00762can...ova c.-mm) plating thickness in seal contact area.Do not65-00-00Rev.4 Page 31

BHT-212-CR&O711140,a11 1e9ITEM NOMENCLATUREMIN.MAXINCHES mm INCHES mm1 Spline - Outer Coupling2 Teeth - Inner Coupling Over pins 2.1590 54.8386 2.1740 55.2196(Use 0.1080 IN. (2.7432 mm)3diameter pins)Spline - Inner Coupling Between pins 1.1465 29.1211 1.1578 29.40812(Use 0.0960 IN. (2.4384 mm)4diameter pins)Spline - Gear Over pins 1.4424 36.63696 1.4465 36.7411(Use 0.0960 IN. (2.4384 mm)5diameter pins)Sleeve ID 2.8340 71.9836 2.8347 72.001386 Sleeve OD 4.4097 112.00638 4.4105 112.02677 Sleeve ID 3.1489 79.98206 3.1497 80.002388 Gear Shaft OD 1.8691 47.47514 1.8696 47.487849 Roller Bearing OD 3.1492 79.98968 3.1496 79.9998410 Gear Shaft OD 1.3780 35.0012 1.3786 35.0164411 Duplex Bearing ID 1.3777 34.99358 1.3781 35.00374OD 2.8341 71.98614 2.8346 71.99884

.BHT-212-CR&0WIRE FEELERGAGE MAXIMUM0.0055 IN.10.1397 mm)POSITION METALSTRAIGHT EDGEPERPENDICULARTO FACE OF, TOOTHBEING INSPECTEDGAGE PIN -GEARMEASUREMENTOVER PINSDETAIL ADETAIL BrGEAR TEETH AND SPLINE MEASURING PIN212-R-65-11-2Figure 65-11. Intermediate gearbox input quill wear limits (sheet 2).-plate external spline teeth on inner coupling.Do not plate internal spline teeth on outercoupling. Apply tape (C-434) to areas not tobe plated. (Refer to figure 65-13 for platingdimensions, and BHT-ALL-SPM for prescribedcadmium plating methods.)cm7. If original cadmium plating on sleeve shimplate (20, figure 65-10) has worn through,replate as follows:oa. Cadmium plate sleeve shim plate usingbrush cadmium plating solution (C-108).Required dimensions shall be met afterplating.b. If original sleeve shim plate is missingor mixed With other shim plates, determinerequired dimensions of replacement shimplate as follows:Oc(1) Examine sleeve for referencedimension which is metal stamped or vibroetchedon sleeve adjacent to applicablemounting surface.(2) Subtract 0.3915 to 0.3910 in.(9.9441 to 9.9314 mm) from dimensionscetched or stamped on sleeve to give requiredshim thickness, after plating.(3) Grind new blank shim to requiredthickness and apply brush cadmium platingsolution (C-108). Using etching ink orequivalent, identify shim plate by etchingserial number of applicable sleeve on shimplate. Also etch thickness on shim plate.Neutralize with water and common bakingsoda after etching.8. Repair sleeve (18) as follows:a. If damaged or loose, replace clinchnuts (19).(1) Use a drift or bolt threaded into nutto drive clinch nut out; being careful not todamage hole in sleeve flange.(2) Clean sleeve by vapor degreasingwith 1.1.1-trichloroethane (C-334).Lfi5-00-00Page 33

BHT-212-CR&OTOPHEEL TOPHEEL i \ TOETOEROOTWEAR PATTERNROOTWEAR PATTERNPinion P/N 212-040-500-7Desired wear pattern on pinionView AGear P/N 212-040-500-6Desired wear pattern on gearView BIROOT (CONVEX SIDE)Gear P/N 212-040-500-6View CHEELTOPTOEHEELTOPTOEROOTWEAR PATTERNROOTWEAR PATTERNPinion P/N 212-040-500-7Acceptable wear pattern on pinonView DGear P/N 212-040-500-6Acceptable wear pattern on gearView E212-R-65-12-100000Figure 65-12. Gear and pinion wear patterns (sheet 1 of 3)65-00-00Page 34 Rev. 3

BHT-212-CR&OROOTPinion P/N 212-040-500-7WEAR PATTERNAcceptable wear pattern on pinionview FPinion P/N 212-040-500-6Acceptable wear pattern on gearview GNOTES1. Wear pattern inspection: Observe the visible gear contact wear pattern on the concave side ofthe pinion teeth and on the convex side of the gear teeth. The teeth on the pinion have a leftspiral and the teeth of the gear have a right spiral.u°, a.:C.Ofl.cot de.taeQ>0005-0CC>,a_0.3fl.Las#0+ashfl.91°X'O.modpipc..2. The desired wear pattern is shown in Views A and B. A speckled or mottled appearance in theflank of the pinion or top of the gear due to dulite removal is permissable. The wide and not toowell defined toe pattern is characteristic of this gear set. The area of the wear pattern in the flankof the gear is very faint and propper lighting must be used in order to see it.3. Acceptable wear patterns are shown in Views D, E, F, and G. These views show various toe andheel locations, and different severities of the speckled or mottled appearance in the flank of thepinion and top of gear.4. Pattern limits at toe: The pattern may touch the toe or be a maximim of 1/8 inch (3.175 mm) fromtoe on gear (View C). Usually the pattern will touch the toe in the flank of the pinion and at the topof the gear as shown in Views D and E. If the pattern touches the toe but is more than 1/8 inch(3.175 mm) from heel on gear member, then the pattern is off the toe and is not acceptable. Thismethod of inspection must be used, due to the wide toe pattern, to determine whether thepattern is just touching the toe or is running off the toe. Pattern variation at the toe must notexceed 1/32 inch (0.79375 mm).5. Pattern limits at heel: The pattern may touch the heel or be a maximum of 1 /8 inch (3.175 mm)from heel on gear member (View C). Pattern variation at heel must not exceed 1/32 inch (0.79375mm).>~,C1^ 3D1fl..C=tip6. Pattern profile: The pattern in the profile direction must touch or extend over the top of thepinion as shown by Views A, D and F. On the gear, the pattern may be 1/32 inch (0.79375 mm)from the top or may extend over the top. Most of the gear patterns will extend over the top asshown by Views B, E and G. A bright Iline occurring at the top of pinion or in flank of the gear iscause for rejection.CID -°,E212-R-65-12-200000°°u1Figure 65-12. Gear and pinion wear patterns (sheet 2)65-00-00Page 35

.-.BHT-212-CR&ONOTES7. Unacceptable defects: In addition to pattern size and location, examine the drive face of all gearteeth for the following defects which are not acceptable if they can be felt with a scribe having a0.002 inch (0.051 mm) radius spherical point.a. Nonclean up g. Dentsb. Grinding scratches h. Grinding flats or barber polingc. Pitting (evidenced by diagonal streaks in the wear pattern)d. Corrosion i. Scuffinge. Cuts j. Scoringf. Nicks k. Inclusions1..fl.212-R-65-12-300000Figure 65-12. Gear and pinion wear patterns (sheet 3)(3) Clean up surface of sleeve flange toremove any raised burrs.N-0.-. .-.(4) Treat hole and any reworked areason sleeve with chromic acid (C-103).(5) If clinch nut was not loose, coat newnut with primer (C-201) and drive nut (19) intoplace. Remove any raised burrs on sleeveflange face, and touch up with chromic acid(C-103).(S34-.0o.((

BHT-212-CR&OA Acceptable pattern typical of low operatingtime.B Acceptable pattern typical of couplings whichhave operated with normal misalignment for alonger period of time than that shown in A.O.0.,oC Acceptable pattern denoting operation athigher torque than that shown in A and B.t..oafD Acceptable pattern showing a pitted tooth.This condition is acceptable on all teeth.EPattern shows a more severe condition oftooth pitting than that shown in D. There isno metal projecting above the normal face ofthe tooth, indicating that the pitted area ispolishing over. This condition may exist on allteeth. Couplings with pits larger than 1/32a.3C=sE oInch (0.79375 mm) diameter should be replaced.212-R-65-1300000Figure 65-13.Quill coupling teeth wear patterns65-00-00Page 37

BHT-212-CR&OACCEPTABLE212-R-65-14UNACCEPTABLE 00000Figure 65-14.Quill roller bearing wear pattern(3) Treat sleeves with corrosion c. Cadmium plated steel parts: TreatOHO-ti1-'2(DOEDdamage within acceptable limits by immersionin a chromic acid bath (BHT-ALL-SPM).c. Perform fluorescent penetrantinspection of sleeve (BHT-ALL-SPM).rework areas with brush cadmium platingsolution (C-108) (BHT-ALL-SPM).,-.11. Replace outer coupling TEMP-PLATES if Inecessary (Paragraph 65-9A).65.9. Repair nicks, scratches, and burrs onpinion splines and teeth by dressing withIndia stone (C-464).065-28. Assembly.-MATERIALS REQUIRED10. Refinish parts, after repair (BHT-ALL-SPM), as outlined below:0)I-((DDa. Aluminum parts: Touch up withEchemical film material (C-100).b. Magnesium parts: Remove all traces ofcorrosion by immersion in chromic acid bath(BHT-ALL-SPM). Touch up parts with chromicacid (C-103) or treat entire part with,-+'-'magnesium alloy chemical film treatment(BHT-ALL-SPM).NUMBERNOMENCLATUREC-010 Lubricating OilC-015 Lubricant (Tube Pack)C-308 AdhesiveC-405 Lockwi re65-00-00Page 38Rev.3

c.BHT-212-CR&0AREA BDIM. CNOTES1. Corrosion pitting or mechanical surface damage in area A, exclusive of area B, is acceptable provided it iswithin the following limits:a. Maximum acceptable depth is 0.030 inch (0.762 mm).b. No more than 40 percent of the area within any one inch square, nor 20 percent of the total area of anysurface or diameter may be pitted.2. Corrosion pitting or mechanical surface damage on the spot faced surface at the attaching holes, area B, isacceptable provided it is within the following limits:-oO OO Oc c c.--l- - -c .. o --- -Maximum acceptable depth is 0.020 inch (0.508b. No more than 20 percent of the total spot faced area at any hole may be pitted.c. No more than 20 percent of the total area normally contacted by the washer may be pitted.3d. No more than 50 percent of the width of the area normally contacted by the washer maybe pitted at anypoint around the hole.o212-R-65-15Figure 65-15.Quill sleeve damage limits65-00-00Page 39

BHT-212-CR&ONUMBERT101307T101333T101334T101564T101600D-KSPECIAL TOOLS REQUIREDNOMENCLATUREWrenchPressing barPressing barHolding fixtureWrench'CAUTION'SAME SHIM PLATE (20, FIGURE65-10) REMOVED FROM SLEEVESHALL BE REINSTALLED OR ANEW SHIM PLATE OF SAMETHICKNESS SHALL BE MADE.D=mm>mm1. Coat all parts with gearbox oil prior tostarting reassembly procedure.02. Position original shim plate (20, figure 65-10) or new shim plate on sleeve (18) andinstall three screws (21).3. Press duplex ball bearing (17) into sleeve(18) using T101334 pressing bar. Duplexbearing shall have matching serial numbers,be installed in pairs, and be installed face-toface.4. Press roller bearing (27) into sleeve (18)using T101333 pressing bar. Install retainingring (26).I.................WHEN INSTALLING PINION INTOBEARING, USE CARE TO APPLYPRESSURE ONLY TO PINION HUBAREA. PRESSURE APPLIED ATGEAR TEETH CAN RESULT INCRACKS BETWEEN HOLES INWEB, AND POSSIBLE FAILURE OFPINION.V115. Press pinion (25) into sleeve whilesupporting inner race of duplex ball bearing(17). Avoid damage to teeth of pinion....V)=^Q_..N^>(n=wQ:3(CD6. Apply adhesive (C-308) to faying surfaceof seal (14) and nut (15). Press new seal(14) into nut (15) with lip of seal facing-;^j°-Nom-iv=(D-inboard. Install new packing (16) on nut (15).Position T101564 holding fixture on sleeve(18) with pins engaged through holes insleeve flange. Coat packing and threads ofnut (15) with gearbox oil. Install nut in sleeveand torque 100 to 150 ft.lbs. (135.58 to203.37 Nm) using T101600 wrench. Securenut to sleeve with lockwire (C-405).NOTEA workaid may be fabricated (figure65-2, detail B) to aid installation ofseal (13).7. Install seal (13) into outer coupling (11)seal groove as follows:a. Apply a light coat of lubricant (tubepack) (C-015) to outer circumference of seal(13).b. Install seal (13) into outer coupling (11)seal groove with lip of seal toward internalsplines of outer coupling (11), as shown infigure 65-10, detail A.NOTE:=3Seal (13) will be partially seated andinner coupling (10) will be used as abackup, in reverse (see detail A) tofully seat outer circumference edgeof seal into outer coupling (11) sealgroove.c. Using inner coupling (10) as a backup,and placed, as shown in detail A, firmly pressdown (hand pressure only) on outer coupling(11), simultaneously tuck outer circumferenceedge of seal (13) with workaid (figure 65-2,detail B) into outer coupling (11, figure 65-10)seal groove.d. Continue pressing around seal (13)with workaid until seal (13) is fully seated.65-00-00Page 40

0BHT-212-CR&ORemove inner coupling (10) from outercoupling (11).08. Place small amount of lubricant (tubepack) (C-015) in internal splines of outercoupling (11) and on inboard side of seal(13). Insert inner coupling (10) into outer00CL-...coupling (11) with small end through seal.NOTEEnsure inner coupling (10) is correctfor intermediate and tail rotorgearbox, overall length is 1.870 to1.880 in. (47.498 to 47.752 mm).<strong>Tail</strong> rotor driveshaft hanger couplingoverall length is 2.07 to 2.08 in.(52.578 to 52.832 mm).9. Position couplings (10 and 11) on splinedend of pinion (25).010. Coat threads of coupling retaining bolt(2) with lubricating oil (C-010).11. Place washer (1) on bolt and thread boltinto pinion.012. Hold outer coupling (11) with T101307wrench. Use a square extension to torque bolt(2) 80 to 100 ft.lbs. (108.464 to 135.58 Nm).13. Place packing (3) on retainer (4).alignment. When hole and notch are aligned,install lock spring (6) through hole in rim orretainer and notch of inner coupling (10).(QCu-6W..3+mo(a0'(QDa0,C?O15. Extend outer coupling (11) so that seal(13) is against teeth of inner coupling. Coatinternal splines of outer coupling (11) withlubricant (tube pack) (C-015) to 0.12 in.(0.3048 mm) depth over top of spline teeth. Aworkaid may be fabricated (figure 65-2, detailC) to obtain depth of grease.16. Place small end of centering spring (7,figure 65-10) on boss of seal plate (8).17. Install plate (8), spacer (5), and0)^centering spring (7) into coupling and installretainer ring (9).18. Place new packing (24) on plug (23).Coat packing and plug with lubricating oil (C-010), and insert plug into pinion (25). Installretainer ring (22).19. Test quill by holding sleeve and turningcoupling. There should be a very light dragcaused by oil seal and preload of the duplexbearings, but coupling and pinion should turnsmoothly.-CL20. Tag quill with with date of lubrication andmake entry in component historical record ifquill is to be returned to stock.21. When quill is installed on helicopter, anentry will be made in helicopter log and flexcouplings lubrication log.22. Deleted. 014. Coat packing and retainer withlubricating oil (C-010), and insert retainer intobolt (2). If one hole in rim of retainer (4) doesnot align with notch of inner coupling (10),pull retainer free of bolt, rotate 90 degreesand reinstall. Repeat if necessary to obtain"-'U-'+0.65-00-00Figure 65-16. DELETED Rev. 3 Page 41/'42

BHT-212-CR&065-29. OUTPUT QUILL.65-30. Disassembly.NUMBERT101307T101333T101334T101564T101600M-0SPECIAL TOOLS REQUIREDzNOMENCLATUREWrenchPressing barPressing barHolding fixtureWrenchNOTEmIf output quill is being disassembledfor replacement of part(s) instead ofoverhaul, disassemble only to extentnecessary.NOTEFor ease of maintenance, blockouter coupling to remain in outboard(extended) position. This willstabilize outer coupling duringdisassembly and assembly.1. Remove retainer ring (1, figure 65-17),plate (2), centering spring (3), and lock spring(4)2. Remove spacer (5).3. Remove retainer (6). A 1/4-20 threadedbolt may be used to facilitate removal ofretainer (6). Install bolt in center of retainerand pull on bolt to withdraw retainer frominner coupling.'cuQ:34. Remove packing (7) from retainer (6).5. Hold outer coupling (11) with T101307wrench. Position square adapter throughwrench and seat in coupling retainer bolt (8).Remove bolt (8) and washer (9)..-1F--.-.6. Remove couplings (10 and 11) from gear(24).7. Separate couplings (10 and 11), andremove seal (13) from outer coupling (11).8. Position T101564 holding fixture onsleeve (18) with pins engaged through sleeveflange. Remove nut (15) with T101600wrench.9. Remove packing (16) and press seal (14)out of nut (15).10. Press gear (24) out of sleeve (18) usingpressing bar (T101333). Remove ring (23)and roller bearing (22)..EOK)11. Press duplex ball bearing (17) out ofsleeve using pressing bar (T101334).NOTE....o(DON-.0Duplex bearings shall be retained orreplaced as a matched serializedset.12. Remove ring (29), oil collector sleeve(28), and oil collector cone (26).13. Remove packings (25 and 27).14. Remove three screws (21) and shimplate (20). Identify shim plate for reinstallationon same sleeve.65-31. Cleaning.MATERIALS REQUIREDRefer to BHT-ALL-SPM for specification andsource.NUMBERNOMENCLATUREC-105 Corrosion PreventiveC-304 SolventC-334 1.1.1-TrichloroethaneC-436 Paint Remover1. Clean quill parts with solvent (C-304)with exception of bearings which are cleanedwith 1.1.1-trichloroethane (C-334).65-00-00Rev.4 Page 43

BHT-212-CR&O02. Use clean, lint-free cloth or low pressure,filtered, compressed air to dry parts. Do notallow bearings to spin while drying.3. If not used immediately after cleaning,coat bearings with gearbox oil. Do not handleunoiled bearings with bare hands.4. Remove sealant from quill sleeve withplastic scraper.5. Remove paint from quill sleeve with paintremover (C-436) and rinse with clean water.6. If not used immediately after cleaning,gently agitate parts in corrosion preventive(C-105) and air dry. Apply protective coat ofgearbox oil.65-32. Conditional Inspection.0.0M._0>,r.-fNOTE

0BHT-212-CR&O5. Perform magnetic particle inspection ofgear (24) and couplings (10 and 11) (BHT-ALL-SPM).r.0)C/)6. Perform fluorescent penetrant inspectionof sleeve (18) (BHT-ALL-SPM)._,,cam(,DNOTEIf steps 1. through 5. above revealcracks or distortion indicative ofexcessive loads, quill shall beconsidered unserviceable andnonreparable.00+(aX-007. Accomplish Normal Inspection (paragraph65-33).65-33. Normal Inspection.1. Inspect parts dimensionally and replaceparts which exceed inspection limits (figure65-19).NOTEWear limits are provided to showrequired fit between mating parts. Itis not intended all dimensions bechecked as prescribed overhaulprocedure. However, parts exhibitingevidence of wear or physicaldamage shall be checkeddimensionally.2. Inspect gear (24, figure 65-17) splines forchipped, broken, or worn teeth.3. Inspect gear (24) teeth for excessivewear, scoring, scuffing, and wear pattern(figure 65-12).NOTEOvertemperature indicator dots ontemperature indicator TEMP-PLATES are of a white or light graycolor and turn black when exposedto an overtemperature condition.Chemical contamination can alsocause the indicating dots to turnblack.4. Inspect outer coupling (11) temperature(a>((DDindicator TEMP-PLATES for evidence ofo v e r t e m p e r a t u r e indication. Ifovertemperature indication is noted, performcoupling overtemperature inspection asfollows:'Z;Q_00X00ca. Inspect outer coupling cadmium platingfor being discolored (circumferential tan orlight brown band) or blistered. If cadmiumplate discoloration or blistering is found,replace outer coupling and inner coupling.b. Inspect gear teeth of outer couplingand inner coupling for being discolored(brown or blue) in the normally bright contactpatterns. If discoloration is found, replaceouter coupling and inner coupling.07(Q_Q

BHT-212-CR&O24NOTESLocation of temperature indicator TEMP-PLATES.Apply sealant (C-308) on nut (15) and sleeve (18)after assembly....1. Retainer ring 17. Duplex bearing2. Plate 18. Sleeve3. Centering spring 19. Clinch nut4. Lock spring 20. Shim plate5. Spacer 21. Screw6. Retainer 22. Roller bearing7. Packing 23. Retaining ring8. Bolt 24. Gear9. Washer 25. Packing10. Inner coupling 26. Cone11. Outer coupling 27. Packing12. Deleted 28. Sleeve13. Seal 29. Retainer ring14. Seal15. Nut16. Packingd=.c212-R-65-17-1Figure 65-17. Intermediate gearbox output quill (sheet 1 of 2)65.00-00Rev. 3 Page 45oar

BHT-212-CR&0SEAL (13) PARTIALLY SEATEDINTERNALSPLINESINNER COUPLING (10) USEDAS BACK-UP TO PUSH LIPOF SEAL 0 3) UPOUTER COUPLING 01)INSTALLEDINVERTED ON INNERCOUPLINGSEAL 03) FULLY SEATEDDETAIL A212-R-65-17-2212-040-003-1715. Inspect couplings (10 and 11).a))QUAr0,(I)0.0D0Figure 65-17. Intermediate gearbox output quill (sheet 2)a. Inspect for chipped, pitted, cracked, orexcessively worn teeth.3-0b. Check wear patterns to criteria shownon figure 65-18.a-+0)Y=0031(Q0C. Inspect surface of inner couplings thatare contacted by seals (14, figure 65-17) forexcessive wear, nicks, and scratches. Agroove worn by seal is acceptable to aminimum diameter of 1.587 inch (40.3098mm) provided depth does not exceed 0.002inch (0.0508 mm). If groove is smooth, partmay be reworked.6. Inspect following parts by magneticparticle (Code M) or fluorescent penetrant(Code F) (BHT-ALL-SPM), as applicable.Demagnetize parts after magnetic inspection.Figure,Index No.Nomenclature+.,c_0Code65-17, 10 Inner coupling M65-17, 11 Outer coupling M65-17, 8 Bolt M65-17, 24 Gear M65-17, 6 Retainer F65-17, 2 Plate F65-17, 15 Nut F65-17, 18 Sleeve F7. Check bearings (17 and 22, figure 65-17)for smooth operation and indications ofexcessive wear. Inspect bearing races forroughness.8. Inspect bearing liners for scoring andsecurity of mounting in sleeve (28).((DD(OD-G:0C'-' 0_0O(OD0 o09. Inspect bearings for evidence of spalling,scoring, pitting, brinelling, flaking, corrosionon rolling elements, and cracked or brokenretainers (figure 65-14).000wa. Minor nicks, cuts, or scratches areacceptable provided they are too small to befelt with a probe having an end radius of0.030 inch (0.762 mm), and provided totalaffected area does not exceed 10% of contactarea at any point.0b. Minor circumferential scoring isacceptable on rollers and races provided itcannot be felt with a probe having an endradius of 0.030 inch (0.762 mm) and providedaffected area does not exceed 10% of contactarea at any point.(3D65-00-00Page 46 Rev. 4

BHT-212-CR&OA Acceptable pattern typical of low operatingtime.B Acceptable pattern typical of couplings whichhave operated with normal misalignment for alonger period of time than that shown in A.tW//C Acceptable pattern denoting operation athigher torque than that shown in A and B.1D Acceptable pattern showing a pitted tooth.This condition is acceptable on all teeth.a01.QCEPattern shows a more severe condition oftooth pitting than that shown in D. There isno metal projecting above the normal face ofthe tooth, indicating that the pitted area ispolishing over. This condition may exist on allteeth. Couplings with pits larger than 1/32c4.?S,6Inch (0.79375 mm) diameter should be replaced.212-R-65-18cooooFigure 65-18.Intermediate gearbox coupling wear pattern65-00-00Page 47