Tail Rotor Driveshaft Hanger

Tail Rotor Driveshaft Hanger

Tail Rotor Driveshaft Hanger

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

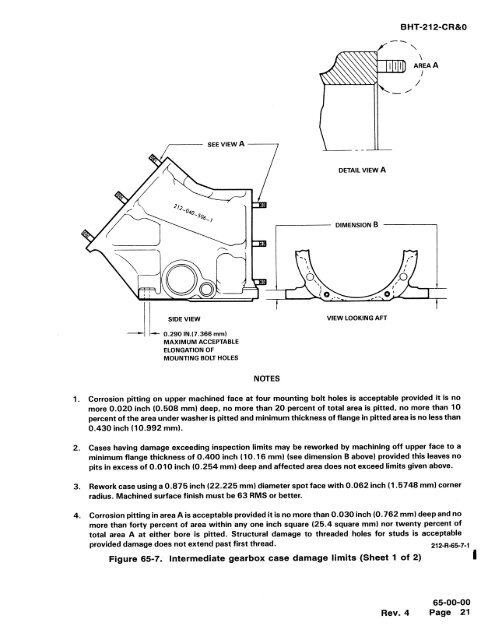

BHT-212-CR&0SIDE VIEWVIEW LOOKING AFT0.290 IN.17.366 mm)MAXIMUM ACCEPTABLEELONGATION OFMOUNTING BOLT HOLESNOTES1. Corrosion pitting on upper machined face at four mounting bolt holes is acceptable provided it is nomore 0.020 inch (0.508 mm) deep, no more than 20 percent of total area is pitted, no more than 10percent of the area under washer is pitted and minimum thickness of flange in pitted area is no less than0.430 inch (10.992 mm).2. Cases having damage exceeding inspection limits may be reworked by machining off upper face to aminimum flange thickness of 0.400 inch (10.16 mm) (see dimension B above) provided this leaves nopits in excess of 0.010 inch (0.254 mm) deep and affected area does not exceed limits given above.CI)3. Rework case using a 0.875 inch (22.225 mm) diameter spot face with 0.062 inch (1.5748 mm) cornerradius. Machined surface finish must be 63 RMS or better.°)yCSI4. Corrosion pitting in area A is acceptable provided it is no more than 0.030 inch (0.762 mm) deep and nomore than forty percent of area within any one inch square (25.4 square mm) nor twenty percent oftotal area A at either bore is pitted. Structural damage to threaded holes for studs is acceptableprovided damage does not extend past first thread.a..coo=E°-'Figure 65-7. Intermediate gearbox case damage limits (Sheet 1 of 2),C+212-R-65-7-1i65-00-00Rev.4 Page 21