Tail Rotor Driveshaft Hanger

Tail Rotor Driveshaft Hanger

Tail Rotor Driveshaft Hanger

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

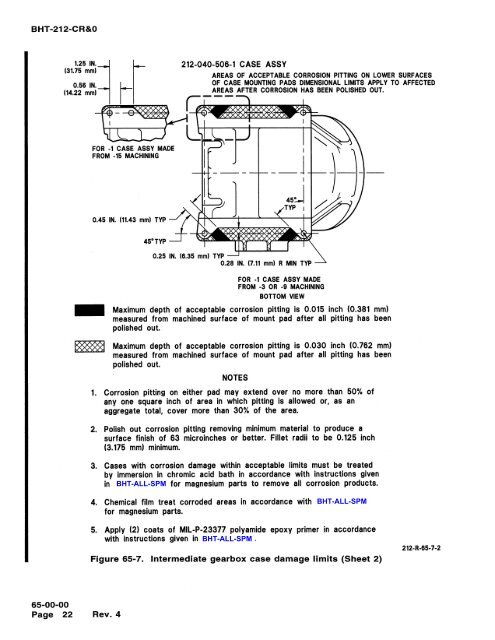

BHT-212-CR&O.w.212-040-506-1 CASE ASSYAREAS OF ACCEPTABLE CORROSION PITTING ON LOWER SURFACESOF CASE MOUNTING PADS DIMENSIONAL LIMITS APPLY TO AFFECTEDAREAS AFTER CORROSION HAS BEEN POLISHED OUT.-DrFOR -1 CASE ASSY MADEFROM -15 MACHINING0.25 IN. (6.35 mm) TYP0.28 IN. (7.11 mm) R MIN TYP(fltri==O30,-0..L.FOR -1 CASE ASSY MADEFROM -3 OR -9 MACHINING>-:E00:E EBOTTOM VIEWMaximum depth of acceptable corrosion pitting is 0.015 inch (0.381 mm)measured from machined surface of mount pad after all pitting has beenpolished out.Maximum depth of acceptable corrosion pitting is 0.030 inch (0.762 mm)measured from machined surface of mount pad after all pitting has beenpolished out.NOTES1. Corrosion pitting on either pad may extend over no more than 50% ofany one square inch of area in which pitting is allowed or, as anaggregate total, cover more than 30% of the area.2. Polish out corrosion pitting removing minimum material to produce asurface finish of 63 microinches or better. Fillet radii to be 0.125 inch(3.175 mm) minimum.3. Cases with corrosion damage within acceptable limits must be treatedby immersion in chromic acid bath in accordance with instructions givenin BHT-ALL-SPM for magnesium parts to remove all corrosion products.4. Chemical film treat corroded areas in accordance with BHT-ALL-SPMfor magnesium parts.+L+....O.f/)G))5. Apply (2) coats of MIL-P-23377 polyamide epoxy primer in accordancewith instructions given in BHT-ALL-SPM.Figure 65-7. Intermediate gearbox case damage limits (Sheet 2)212-R-65-7-265-00-00Page 22Rev.4