Tail Rotor Driveshaft Hanger

Tail Rotor Driveshaft Hanger

Tail Rotor Driveshaft Hanger

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

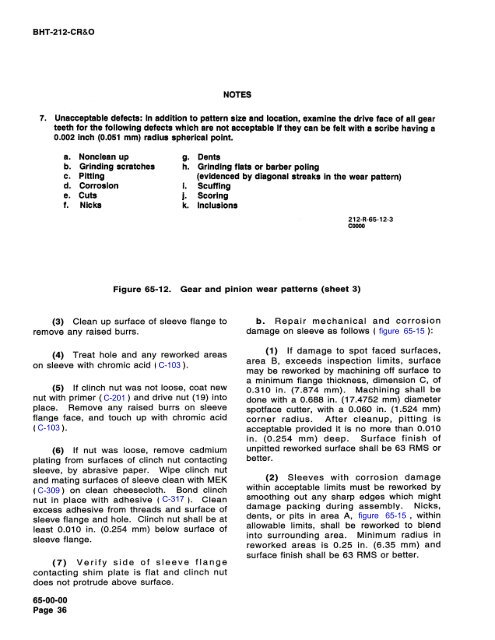

.-.BHT-212-CR&ONOTES7. Unacceptable defects: In addition to pattern size and location, examine the drive face of all gearteeth for the following defects which are not acceptable if they can be felt with a scribe having a0.002 inch (0.051 mm) radius spherical point.a. Nonclean up g. Dentsb. Grinding scratches h. Grinding flats or barber polingc. Pitting (evidenced by diagonal streaks in the wear pattern)d. Corrosion i. Scuffinge. Cuts j. Scoringf. Nicks k. Inclusions1..fl.212-R-65-12-300000Figure 65-12. Gear and pinion wear patterns (sheet 3)(3) Clean up surface of sleeve flange toremove any raised burrs.N-0.-. .-.(4) Treat hole and any reworked areason sleeve with chromic acid (C-103).(5) If clinch nut was not loose, coat newnut with primer (C-201) and drive nut (19) intoplace. Remove any raised burrs on sleeveflange face, and touch up with chromic acid(C-103).(S34-.0o.((