Tail Rotor Driveshaft Hanger

Tail Rotor Driveshaft Hanger

Tail Rotor Driveshaft Hanger

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

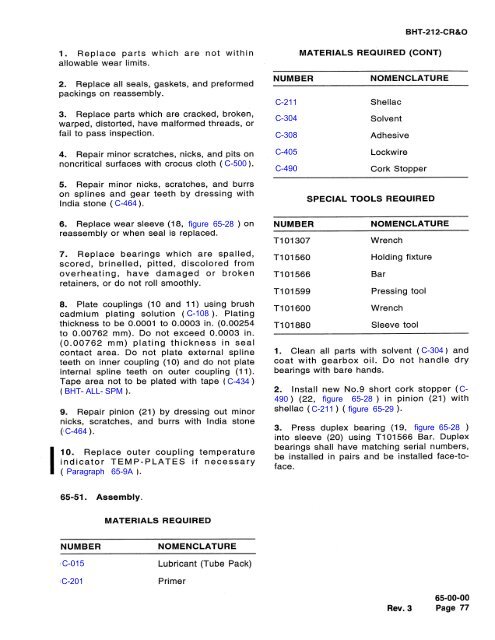

BHT-212-CR&O1. Replace parts which are not withinallowable wear limits.2. Replace all seals, gaskets, and preformedpackings on reassembly.3. Replace parts which are cracked, broken,warped, distorted, have malformed threads, orfail to pass inspection.ma) vow4. Repair minor scratches, nicks, and pits onnoncritical surfaces with crocus cloth (C-500).5. Repair minor nicks, scratches, and burrson splines and gear teeth by dressing withIndia stone (C-464).a-0)a00((DD(fl(.) c((D(O)+U' tea) a)4O',.+6. Replace wear sleeve (18, figure 65-28) onreassembly or when seal is replaced.7. Replace bearings which are spalled,scored, brinelled, pitted, discolored fromoverheating, have damaged or brokenQ00retainers, or do not roll smoothly.8. Plate couplings (10 and 11) using brushcadmium plating solution (C-108). Platingthickness to be 0.0001 to 0.0003 in. (0.00254to 0.00762 mm). Do not exceed 0.0003 in.(0.00762 mm) plating thickness in sealcontact area. Do not plate external splineteeth on inner coupling (10) and do not plateinternal spline teeth on outer coupling (11).Tape area not to be plated with tape (C-434)(BHT-ALL-SPM).9. Repair pinion (21) by dressing out minornicks, scratches, and burrs with India stone(C-464).10. Replace outer coupling temperatureindicator TEMP-PLATES if necessary(Paragraph 65-9A)._.(Q((c .j.NUMBERC-211C-304C-308C-405C-490NUMBERT101307T101560T101566T101599T101600I--T101880MATERIALS REQUIRED (CONT)NOMENCLATUREShellacSolventAdhesiveLockwi reCork StopperSPECIAL TOOLS REQUIREDNOMENCLATUREWrenchHolding fixtureBarPressing toolWrenchSleeve tool01. Clean all parts with solvent (C-304) andcoat with gearbox oil. Do not handle drybearings with bare hands.2. Install new No.9 short cork stopper (C-490) (22, figure 65-28) in pinion (21) withshellac (C-211) (figure 65-29).3. Press duplex bearing (19, figure 65-28)into sleeve (20) using T101566 Bar. Duplexbearings shall have matching serial numbers,be installed in pairs and be installed face-toface..4.65-51. Assembly.MATERIALS REQUIREDNUMBERNOMENCLATUREC-015 Lubricant (Tube Pack)C-201 Primer65-00-00Rev. 3 Page 77