Tail Rotor Driveshaft Hanger

Tail Rotor Driveshaft Hanger

Tail Rotor Driveshaft Hanger

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

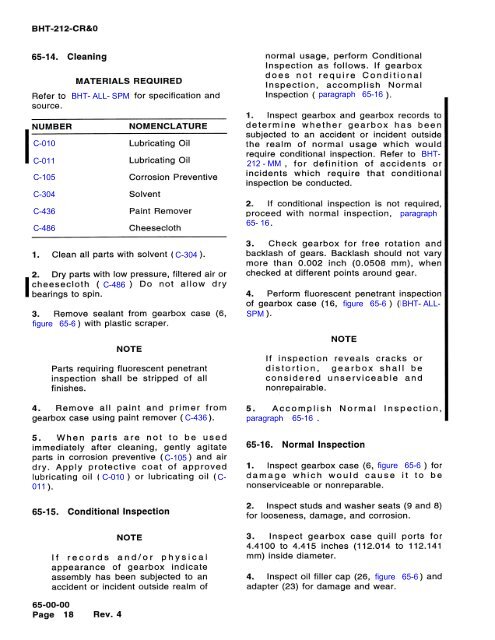

BHT-212-CR&0I65-14. Cleaningmm300MATERIALS REQUIREDRefer to BHT-ALL-SPM for specification andsource.NUMBERC-010 Lubricating OilC-011 Lubricating OilNOMENCLATUREC-105 Corrosion PreventiveC-304 SolventC-436 Paint RemoverC-486 Cheesecloth1. Clean all parts with solvent (C-304).2. Dry parts with low pressure, filtered air orcheesecloth (C-486) Do not allow drybearings to spin.3. Remove sealant from gearbox case (6,figure 65-6) with plastic scraper.NOTEParts requiring fluorescent penetrantinspection shall be stripped of allfinishes.4. Remove all paint and primer fromgearbox case using paint remover (C-436).(°)(CDO'605. When parts are not to be usedimmediately after cleaning, gently agitateparts in corrosion preventive (C-105) and airdry. Apply protective coat of approvedlubricating oil (C-010) or lubricating oil (C-011).65-15. Conditional InspectionIfNOTErecords and/or physicalappearance of gearbox indicateassembly has been subjected to anaccident or incident outside realm ofr-0normal usage, perform ConditionalInspection as follows. If gearboxdoes not require ConditionalInspection, accomplish NormalInspection (paragraph 65-16).1. Inspect gearbox and gearbox records todetermine whether gearbox has beensubjected to an accident or incident outsidethe realm of normal usage which would=30require conditional inspection. Refer to BHT-(DD:.,212-MM, for definition of accidents orincidents which require that conditionalinspection be conducted..-.(NDD))E-i.2. If conditional inspection is not required,proceed with normal inspection, paragraph65-16.0°:3o-c1-03. Check gearbox for free rotation andbacklash of gears. Backlash should not varymore than 0.002 inch (0.0508 mm), whenchecked at different points around gear.4. Perform fluorescent penetrant inspectionof gearbox case (16, figure 65-6) (BHT-ALL-SPM).NOTEIf inspection reveals cracks ordistortion, gearbox shall beconsidered unserviceable andnonrepairable.5. Accomplish Normal Inspection,paragraph 65-16.65-16. Normal Inspection1. Inspect gearbox case (6, figure 65-6) fordamage which would cause it to benonserviceable or nonreparable.2. Inspect studs and washer seats (9 and 8)for looseness, damage, and corrosion.3. Inspect gearbox case quill ports for4.4100 to 4.415 inches (112.014 to 112.141mm) inside diameter.4. Inspect oil filler cap (26, figure 65-6) andadapter (23) for damage and wear.65-00-00Page 18Rev.4a))