Tail Rotor Driveshaft Hanger

Tail Rotor Driveshaft Hanger

Tail Rotor Driveshaft Hanger

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

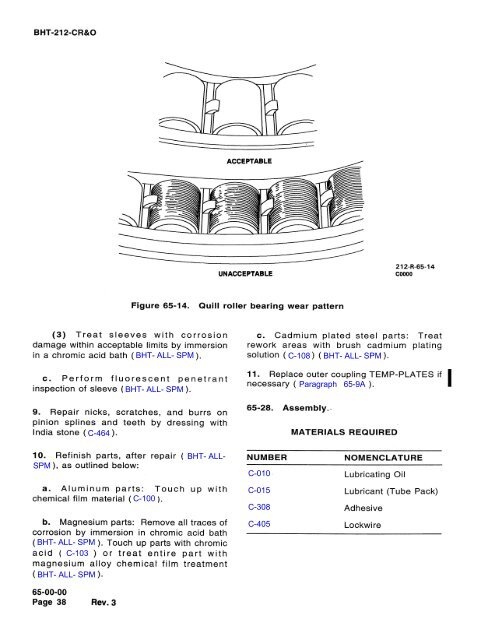

BHT-212-CR&OACCEPTABLE212-R-65-14UNACCEPTABLE 00000Figure 65-14.Quill roller bearing wear pattern(3) Treat sleeves with corrosion c. Cadmium plated steel parts: TreatOHO-ti1-'2(DOEDdamage within acceptable limits by immersionin a chromic acid bath (BHT-ALL-SPM).c. Perform fluorescent penetrantinspection of sleeve (BHT-ALL-SPM).rework areas with brush cadmium platingsolution (C-108) (BHT-ALL-SPM).,-.11. Replace outer coupling TEMP-PLATES if Inecessary (Paragraph 65-9A).65.9. Repair nicks, scratches, and burrs onpinion splines and teeth by dressing withIndia stone (C-464).065-28. Assembly.-MATERIALS REQUIRED10. Refinish parts, after repair (BHT-ALL-SPM), as outlined below:0)I-((DDa. Aluminum parts: Touch up withEchemical film material (C-100).b. Magnesium parts: Remove all traces ofcorrosion by immersion in chromic acid bath(BHT-ALL-SPM). Touch up parts with chromicacid (C-103) or treat entire part with,-+'-'magnesium alloy chemical film treatment(BHT-ALL-SPM).NUMBERNOMENCLATUREC-010 Lubricating OilC-015 Lubricant (Tube Pack)C-308 AdhesiveC-405 Lockwi re65-00-00Page 38Rev.3