Measuring the solder-wave height on wave ... - Micro-Epsilon

Measuring the solder-wave height on wave ... - Micro-Epsilon

Measuring the solder-wave height on wave ... - Micro-Epsilon

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

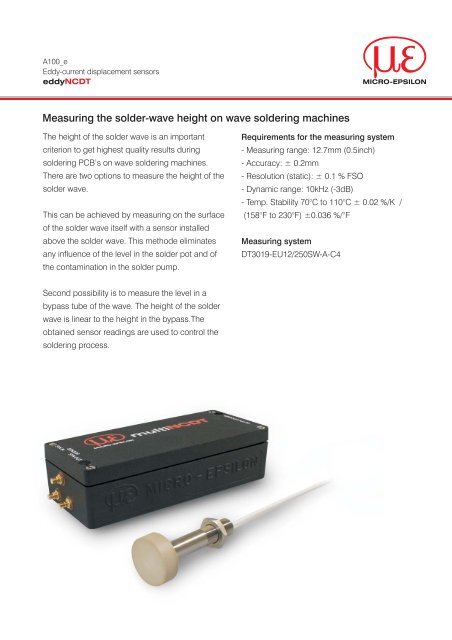

A100_eEddy-current displacement sensorseddyNCDT<str<strong>on</strong>g>Measuring</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>solder</str<strong>on</strong>g>-<str<strong>on</strong>g>wave</str<strong>on</strong>g> <str<strong>on</strong>g>height</str<strong>on</strong>g> <strong>on</strong> <str<strong>on</strong>g>wave</str<strong>on</strong>g> <str<strong>on</strong>g>solder</str<strong>on</strong>g>ing machinesThe <str<strong>on</strong>g>height</str<strong>on</strong>g> of <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>solder</str<strong>on</strong>g> <str<strong>on</strong>g>wave</str<strong>on</strong>g> is an importantcriteri<strong>on</strong> to get highest quality results during<str<strong>on</strong>g>solder</str<strong>on</strong>g>ing PCB’s <strong>on</strong> <str<strong>on</strong>g>wave</str<strong>on</strong>g> <str<strong>on</strong>g>solder</str<strong>on</strong>g>ing machines.There are two opti<strong>on</strong>s to measure <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>height</str<strong>on</strong>g> of <str<strong>on</strong>g>the</str<strong>on</strong>g><str<strong>on</strong>g>solder</str<strong>on</strong>g> <str<strong>on</strong>g>wave</str<strong>on</strong>g>.This can be achieved by measuring <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> surfaceof <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>solder</str<strong>on</strong>g> <str<strong>on</strong>g>wave</str<strong>on</strong>g> itself with a sensor installedabove <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>solder</str<strong>on</strong>g> <str<strong>on</strong>g>wave</str<strong>on</strong>g>. This methode eliminatesany influence of <str<strong>on</strong>g>the</str<strong>on</strong>g> level in <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>solder</str<strong>on</strong>g> pot and of<str<strong>on</strong>g>the</str<strong>on</strong>g> c<strong>on</strong>taminati<strong>on</strong> in <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>solder</str<strong>on</strong>g> pump.Requirements for <str<strong>on</strong>g>the</str<strong>on</strong>g> measuring system- <str<strong>on</strong>g>Measuring</str<strong>on</strong>g> range: 12.7mm (0.5inch)- Accuracy: ± 0.2mm- Resoluti<strong>on</strong> (static): ± 0.1 % FSO- Dynamic range: 10kHz (-3dB)- Temp. Stability 70°C to 110°C ± 0.02 %/K /(158°F to 230°F) ±0.036 %/°F<str<strong>on</strong>g>Measuring</str<strong>on</strong>g> systemDT3019-EU12/250SW-A-C4Sec<strong>on</strong>d possibility is to measure <str<strong>on</strong>g>the</str<strong>on</strong>g> level in abypass tube of <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>wave</str<strong>on</strong>g>. The <str<strong>on</strong>g>height</str<strong>on</strong>g> of <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>solder</str<strong>on</strong>g><str<strong>on</strong>g>wave</str<strong>on</strong>g> is linear to <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>height</str<strong>on</strong>g> in <str<strong>on</strong>g>the</str<strong>on</strong>g> bypass.Theobtained sensor readings are used to c<strong>on</strong>trol <str<strong>on</strong>g>the</str<strong>on</strong>g><str<strong>on</strong>g>solder</str<strong>on</strong>g>ing process.

Applicati<strong>on</strong>Envir<strong>on</strong>mental c<strong>on</strong>diti<strong>on</strong>s- Temperature:- Electr<strong>on</strong>ics 10°C to 50°C (50 to 122°F)- Sensor 10°C to 200°C (50 to 392°F)- Medium (sensor): air, fluxer, liquid <str<strong>on</strong>g>solder</str<strong>on</strong>g> up to300°C (572°F)Selecti<strong>on</strong> criteria- The eddy current-measurement systems works inc<strong>on</strong>taminated envir<strong>on</strong>ment (e.g. fluxer, vapor, ...)- Robust Sensor - short time submersi<strong>on</strong> of <str<strong>on</strong>g>the</str<strong>on</strong>g>sensor in liquid <str<strong>on</strong>g>solder</str<strong>on</strong>g> 300°C (572°F) is possiblewithout any damage- High Temperature stability, by active temperaturecompensati<strong>on</strong>Principle 1: Direct measuringdisplacement sensorliquid <str<strong>on</strong>g>solder</str<strong>on</strong>g>300°CPrinciple 2: <str<strong>on</strong>g>Measuring</str<strong>on</strong>g> by a bypass tubedisplacement sensorbypass tubeMICRO-EPSILONKoenigbacher Str. 1594496 Ortenburg / GermanyTel.: 0 85 42/1 68-0Fax: 0 85 42/1 68 90info@micro-epsil<strong>on</strong>.comwww.micro-epsil<strong>on</strong>.comA member of micro-epsil<strong>on</strong> group.Certified DIN EN ISO 9001 : 2000Modificati<strong>on</strong>s reserved Y9781100-C010058DGO