Automatic tire identification and DOT code reading - Micro-Epsilon

Automatic tire identification and DOT code reading - Micro-Epsilon

Automatic tire identification and DOT code reading - Micro-Epsilon

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

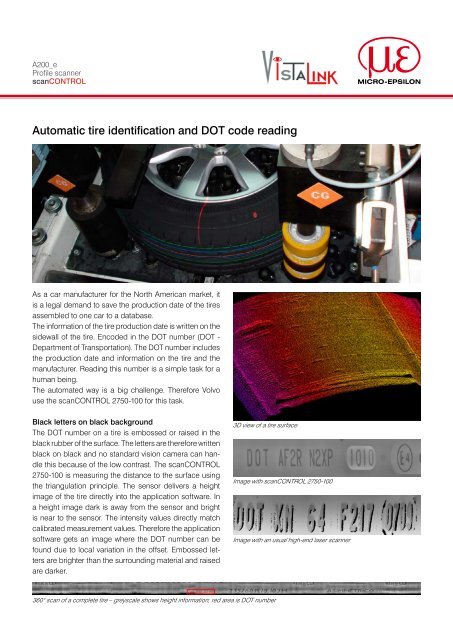

A200_eProfile scannerscanCONTROL<strong>Automatic</strong> <strong>tire</strong> <strong>identification</strong> <strong>and</strong> <strong>DOT</strong> <strong>code</strong> <strong>reading</strong>As a car manufacturer for the North American market, itis a legal dem<strong>and</strong> to save the production date of the <strong>tire</strong>sassembled to one car to a database.The information of the <strong>tire</strong> production date is written on thesidewall of the <strong>tire</strong>. En<strong>code</strong>d in the <strong>DOT</strong> number (<strong>DOT</strong> -Department of Transportation). The <strong>DOT</strong> number includesthe production date <strong>and</strong> information on the <strong>tire</strong> <strong>and</strong> themanufacturer. Reading this number is a simple task for ahuman being.The automated way is a big challenge. Therefore Volvouse the scanCONTROL 2750-100 for this task.Black letters on black backgroundThe <strong>DOT</strong> number on a <strong>tire</strong> is embossed or raised in theblack rubber of the surface. The letters are therefore writtenblack on black <strong>and</strong> no st<strong>and</strong>ard vision camera can h<strong>and</strong>lethis because of the low contrast. The scanCONTROL2750-100 is measuring the distance to the surface usingthe triangulation principle. The sensor delivers a heightimage of the <strong>tire</strong> directly into the application software. Ina height image dark is away from the sensor <strong>and</strong> brightis near to the sensor. The intensity values directly matchcalibrated measurement values. Therefore the applicationsoftware gets an image where the <strong>DOT</strong> number can befound due to local variation in the offset. Embossed lettersare brighter than the surrounding material <strong>and</strong> raisedare darker.3D view of a <strong>tire</strong> surfaceImage with scanCONTROL 2750-100Image with an usual high-end laser scanner360° scan of a complete <strong>tire</strong> – greyscale shows height information; red area is <strong>DOT</strong> number

applicationHigh speed & high accuracyThe <strong>tire</strong>s have to be checked within maximum of4.5sec time to ensure that the complete process is notslowed down. So the scanCONTROL needs to workwith a very high speed on the low contrast surface. ThescanCONTROL 2750 is used with a profile frequency of2000 Hz <strong>and</strong> the sensor delivers over 1 Million calibratedmeasuring points per second. So one height image hasa resolution of up to 640 x 9,000 calibrated measuringpoints.The distance between each profile is 0.2mm as well asthe distance between two points within one profile in orderto create square pixels. Therefore a circle on the tyrelooks a circle in the image, not an ellipse.High data rateBecause the <strong>DOT</strong> number can be on different sides of the<strong>tire</strong>, the application uses two scanCONTROL 2750-100.One sensor for each side of the <strong>tire</strong>. The high data ratecan be achieved due to the high performance interfaceof the scanCONTROL sensors. Gigabit Ethernet orIEEE 1394 (Firewire) are available <strong>and</strong> capable to providethe b<strong>and</strong>width.Perfect synchronisationWhen the <strong>tire</strong> is turned 360 the movement is not continuous.The application requires defined distances betweeneach profile. So it is necessary to synchronize the <strong>tire</strong>movement with the measurement. scanCONTROL 2750offers with its high performing trigger input an easy wayto solve this task.MICRO-EPSILONKönigbacherstr. 1594496 Ortenburg/GermanyTel. +49 (0) 85 42/1 68-0Fax +49(0) 85 42/1 69 90info@micro-epsilon.comwww.micro-epsilon.comA member of micro-epsilon groupCertified DIN EN ISO 9001 : 2000Modifications reserved / 9781200-A011090FHF