KEMPER - Repa-Tec Lastechniek

KEMPER - Repa-Tec Lastechniek

KEMPER - Repa-Tec Lastechniek

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

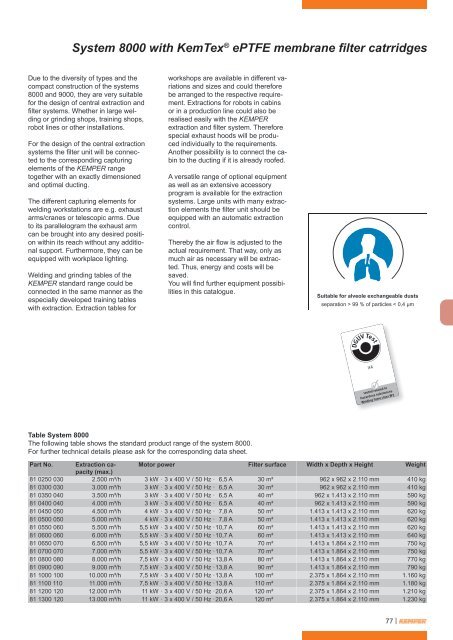

System 8000 with KemTex ® ePTFE membrane filter catrridgesDue to the diversity of types and thecompact construction of the systems8000 and 9000, they are very suitablefor the design of central extraction andfilter systems. Whether in large weldingor grinding shops, training shops,robot lines or other installations.For the design of the central extractionsystems the filter unit will be connectedto the corresponding capturingelements of the <strong>KEMPER</strong> rangetogether with an exactly dimensionedand optimal ducting.The different capturing elements forwelding workstations are e.g. exhaustarms/cranes or telescopic arms. Dueto its parallelogram the exhaust armcan be brought into any desired positionwithin its reach without any additionalsupport. Furthermore, they can beequipped with workplace lighting.Welding and grinding tables of the<strong>KEMPER</strong> standard range could beconnected in the same manner as theespecially developed training tableswith extraction. Extraction tables forworkshops are available in different variationsand sizes and could thereforebe arranged to the respective requirement.Extractions for robots in cabinsor in a production line could also berealised easily with the <strong>KEMPER</strong>extraction and filter system. Thereforespecial exhaust hoods will be producedindividually to the requirements.Another possibility is to connect the cabinto the ducting if it is already roofed.A versatile range of optional equipmentas well as an extensive accessoryprogram is available for the extractionsystems. Large units with many extractionelements the filter unit should beequipped with an automatic extractioncontrol.Thereby the air flow is adjusted to theactual requirement. That way, only asmuch air as necessary will be extracted.Thus, energy and costs will besaved.You will find further equipment possibilitiesin this catalogue.Suitable for alveole exchangeable dustsseparation > 99 % of particles < 0,4 μmTable System 8000The following table shows the standard product range of the system 8000.For further technical details please ask for the corresponding data sheet.Part No. Extraction capacityMotor power Filter surface Width x Depth x Height Weight(max.)81 0250 030 2.500 m³/h 3 kW · 3 x 400 V / 50 Hz · 6,5 A 30 m² 962 x 962 x 2.110 mm 410 kg81 0300 030 3.000 m³/h 3 kW · 3 x 400 V / 50 Hz · 6,5 A 30 m² 962 x 962 x 2.110 mm 410 kg81 0350 040 3.500 m³/h 3 kW · 3 x 400 V / 50 Hz · 6,5 A 40 m² 962 x 1.413 x 2.110 mm 590 kg81 0400 040 4.000 m³/h 3 kW · 3 x 400 V / 50 Hz · 6,5 A 40 m² 962 x 1.413 x 2.110 mm 590 kg81 0450 050 4.500 m³/h 4 kW · 3 x 400 V / 50 Hz · 7,8 A 50 m² 1.413 x 1.413 x 2.110 mm 620 kg81 0500 050 5.000 m³/h 4 kW · 3 x 400 V / 50 Hz · 7,8 A 50 m² 1.413 x 1.413 x 2.110 mm 620 kg81 0550 060 5.500 m³/h 5,5 kW · 3 x 400 V / 50 Hz · 10,7 A 60 m² 1.413 x 1.413 x 2.110 mm 620 kg81 0600 060 6.000 m³/h 5,5 kW · 3 x 400 V / 50 Hz · 10,7 A 60 m² 1.413 x 1.413 x 2.110 mm 640 kg81 0650 070 6.500 m³/h 5,5 kW · 3 x 400 V / 50 Hz · 10,7 A 70 m² 1.413 x 1.864 x 2.110 mm 750 kg81 0700 070 7.000 m³/h 5,5 kW · 3 x 400 V / 50 Hz · 10,7 A 70 m² 1.413 x 1.864 x 2.110 mm 750 kg81 0800 080 8.000 m³/h 7,5 kW · 3 x 400 V / 50 Hz · 13,8 A 80 m² 1.413 x 1.864 x 2.110 mm 770 kg81 0900 090 9.000 m³/h 7,5 kW · 3 x 400 V / 50 Hz · 13,8 A 90 m² 1.413 x 1.864 x 2.110 mm 790 kg81 1000 100 10.000 m³/h 7,5 kW · 3 x 400 V / 50 Hz · 13,8 A 100 m² 2.375 x 1.864 x 2.110 mm 1.160 kg81 1100 110 11.000 m³/h 7,5 kW · 3 x 400 V / 50 Hz · 13,8 A 110 m² 2.375 x 1.864 x 2.110 mm 1.180 kg81 1200 120 12.000 m³/h 11 kW · 3 x 400 V / 50 Hz · 20,6 A 120 m² 2.375 x 1.864 x 2.110 mm 1.210 kg81 1300 120 13.000 m³/h 11 kW · 3 x 400 V / 50 Hz · 20,6 A 120 m² 2.375 x 1.864 x 2.110 mm 1.230 kg77 |