compatibility of ultra high performance concrete as repair material

compatibility of ultra high performance concrete as repair material

compatibility of ultra high performance concrete as repair material

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

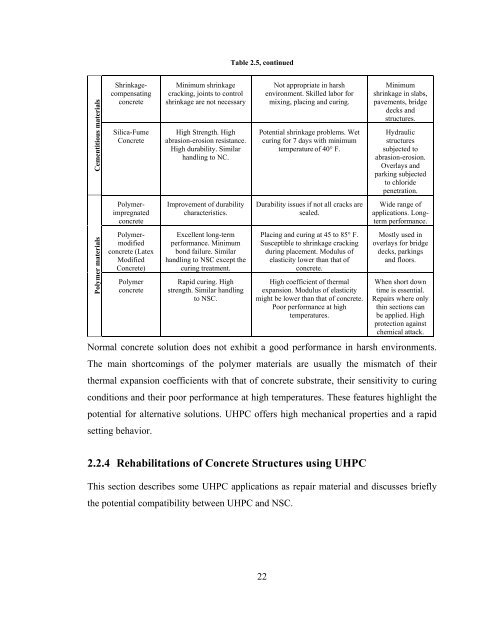

Table 2.5, continuedCementitious <strong>material</strong>sPolymer <strong>material</strong>sShrinkagecompensating<strong>concrete</strong>Silica-FumeConcretePolymerimpregnated<strong>concrete</strong>Polymermodified<strong>concrete</strong> (LatexModifiedConcrete)Polymer<strong>concrete</strong>Minimum shrinkagecracking, joints to controlshrinkage are not necessaryHigh Strength. Highabr<strong>as</strong>ion-erosion resistance.High durability. Similarhandling to NC.Improvement <strong>of</strong> durabilitycharacteristics.Excellent long-term<strong>performance</strong>. Minimumbond failure. Similarhandling to NSC except thecuring treatment.Rapid curing. Highstrength. Similar handlingto NSC.Not appropriate in harshenvironment. Skilled labor formixing, placing and curing.Potential shrinkage problems. Wetcuring for 7 days with minimumtemperature <strong>of</strong> 40° F.Durability issues if not all cracks aresealed.Placing and curing at 45 to 85° F.Susceptible to shrinkage crackingduring placement. Modulus <strong>of</strong>el<strong>as</strong>ticity lower than that <strong>of</strong><strong>concrete</strong>.High coefficient <strong>of</strong> thermalexpansion. Modulus <strong>of</strong> el<strong>as</strong>ticitymight be lower than that <strong>of</strong> <strong>concrete</strong>.Poor <strong>performance</strong> at <strong>high</strong>temperatures.Minimumshrinkage in slabs,pavements, bridgedecks andstructures.Hydraulicstructuressubjected toabr<strong>as</strong>ion-erosion.Overlays andparking subjectedto chloridepenetration.Wide range <strong>of</strong>applications. Longterm<strong>performance</strong>.Mostly used inoverlays for bridgedecks, parkingsand floors.When short downtime is essential.Repairs where onlythin sections canbe applied. Highprotection againstchemical attack.Normal <strong>concrete</strong> solution does not exhibit a good <strong>performance</strong> in harsh environments.The main shortcomings <strong>of</strong> the polymer <strong>material</strong>s are usually the mismatch <strong>of</strong> theirthermal expansion coefficients with that <strong>of</strong> <strong>concrete</strong> substrate, their sensitivity to curingconditions and their poor <strong>performance</strong> at <strong>high</strong> temperatures. These features <strong>high</strong>light thepotential for alternative solutions. UHPC <strong>of</strong>fers <strong>high</strong> mechanical properties and a rapidsetting behavior.2.2.4 Rehabilitations <strong>of</strong> Concrete Structures using UHPCThis section describes some UHPC applications <strong>as</strong> <strong>repair</strong> <strong>material</strong> and discusses brieflythe potential <strong>compatibility</strong> between UHPC and NSC.22