- Page 1 and 2:

COMPATIBILITY OF ULTRA HIGH PERFORM

- Page 3 and 4:

Table of ContentsList of Figures ..

- Page 5 and 6:

4.3.2 Discussion ..................

- Page 7 and 8:

Figure 3.14 CSP index .............

- Page 9 and 10:

Table 4.7 Summary of indirect tensi

- Page 11 and 12:

List of AbbreviationsACI.AFtASTM.CO

- Page 13 and 14:

1 Introduction and MotivationCurren

- Page 15:

2 Background and Literature ReviewT

- Page 18 and 19:

spaces and to decrease the amount o

- Page 20 and 21:

water/binder=constantChoose steel f

- Page 22 and 23: UHPC formulations and provides a se

- Page 24 and 25: Table 2.3Comparison of UHPC materia

- Page 26 and 27: esults obtained in this project wer

- Page 28 and 29: 2.1.3.4 Environmental Impact of UHP

- Page 30 and 31: 1997). Emmons and Vaysburd (1996) d

- Page 32 and 33: e) ConstructabilityIt is recommenda

- Page 34 and 35: Table 2.5, continuedCementitious ma

- Page 36 and 37: • Rehabilitation of a bridge pier

- Page 38 and 39: UHPC is a cost-effective solution i

- Page 40 and 41: apparatus will measure the shear st

- Page 42 and 43: substrate while the scarifying meth

- Page 44 and 45: such test configuration, this upper

- Page 46 and 47: From the equilibrium of forces of F

- Page 48 and 49: The first layer, also called penetr

- Page 50 and 51: 3 MethodologyThis report aims to st

- Page 52 and 53: f sp = 2 ∗ PA ∗ π in psi Equat

- Page 54 and 55: that the bond interface, in this lo

- Page 56 and 57: Ductal® premix is typically compri

- Page 58 and 59: associated test results (temperatur

- Page 60 and 61: Figure 3.2 Detail of splitting tens

- Page 62 and 63: 3.3.3 Pull-off testPull off test wa

- Page 64 and 65: (a) Chipped surface, slightlybrushe

- Page 66 and 67: (a) Molds to cast slant shearspecim

- Page 68 and 69: Timber moulds were used to cast the

- Page 70 and 71: macrotexture depth was measured in

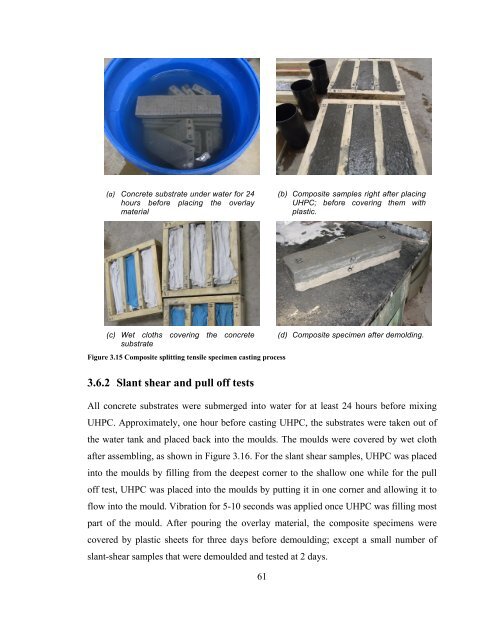

- Page 74 and 75: (a) Concrete substrate under water

- Page 76 and 77: used, as shown in Figure 3.17. A fa

- Page 78 and 79: Equation 2.2 and Equation 2.3 were

- Page 80 and 81: (a) Steel disks glued to the UHPC s

- Page 82 and 83: value to the lowest one in the foll

- Page 84 and 85: Transversal frequency (Hz)255025002

- Page 86 and 87: 115113Relative Dynamic Modulus (%)1

- Page 88 and 89: Only those specimens with a grooved

- Page 90 and 91: Table 4.6, continued.MeanMeanCOV,st

- Page 92 and 93: concrete or bond/concrete while for

- Page 94 and 95: surface treatment applied. In contr

- Page 96 and 97: Table 4.8Summary of slant-shear tes

- Page 98 and 99: (a) B(C): Bond due to concrete fail

- Page 100 and 101: 3143Bond Capacity, (psi)30002500200

- Page 102 and 103: The different failure modes obtaine

- Page 104 and 105: failures occurred in the concrete s

- Page 106 and 107: property of the concrete has higher

- Page 108 and 109: 5.1.1 Combination of Splitting Tens

- Page 110 and 111: 5.1.4 Overall performancea. For thi

- Page 112 and 113: mismatch and load eccentricity. Tho

- Page 114 and 115: 6 ReferenceAbu-Tair, A. I., Rigden,

- Page 116 and 117: Climaco, J. C. T. S., and Regan, P.

- Page 118 and 119: Graybeal, B., and Tanesi, J. (2007)

- Page 120 and 121: Misson, D. (2008). "Influence of Cu

- Page 122 and 123:

Silfwerbrand, J. (1990). "Improving

- Page 124 and 125:

7 Appendix: NSC mix designsTable 7.

- Page 126 and 127:

Table 7.33rd mix for the splitting

- Page 128 and 129:

Table 7.51st mix for the splitting

- Page 130 and 131:

Table 7.73rd mix for the splitting

- Page 132 and 133:

Figure 8.2 Concrete retarder inform

- Page 134 and 135:

Table 9.1, continued.BrBr w/oBr 300

- Page 136 and 137:

Table 9.2, continued.TrialBrushed 6

- Page 138 and 139:

10 Appendix: Splitting tensile pris

- Page 140 and 141:

Table 10.1, continued.128

- Page 142 and 143:

Table 10.1, continued.130

- Page 144 and 145:

Table 10.1, continued.132

- Page 146 and 147:

Table 10.1, continued.134

- Page 148 and 149:

Table 10.2Splitting monolithic NSC

- Page 150 and 151:

11 Appendix: Slant-shear specimens

- Page 152 and 153:

Table 11.1, continued.140

- Page 154 and 155:

Table 12.1, continued.142

- Page 156 and 157:

PortionNumberof 1figures/tables/ill

- Page 158 and 159:

Figure 2.5Miguel Angel Carbonell Mu

- Page 160 and 161:

Miguel Angel Carbonell Munoz Mon, M

- Page 162 and 163:

Miguel - not sure what you need fro

- Page 164 and 165:

End Page 1235Type of UsePortionNumb

- Page 166 and 167:

Type of UseIntended publisher of ot