compatibility of ultra high performance concrete as repair material

compatibility of ultra high performance concrete as repair material

compatibility of ultra high performance concrete as repair material

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

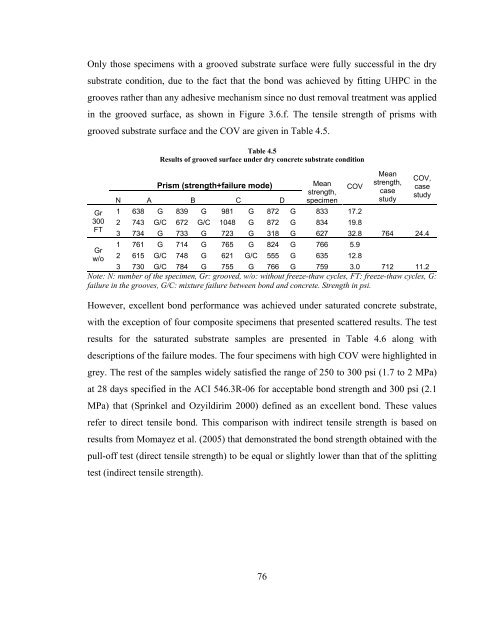

Only those specimens with a grooved substrate surface were fully successful in the drysubstrate condition, due to the fact that the bond w<strong>as</strong> achieved by fitting UHPC in thegrooves rather than any adhesive mechanism since no dust removal treatment w<strong>as</strong> appliedin the grooved surface, <strong>as</strong> shown in Figure 3.6.f. The tensile strength <strong>of</strong> prisms withgrooved substrate surface and the COV are given in Table 4.5.Gr300FTGrw/oTable 4.5Results <strong>of</strong> grooved surface under dry <strong>concrete</strong> substrate conditionPrism (strength+failure mode)Meanstrength,COVN A B C D specimen1 638 G 839 G 981 G 872 G 833 17.22 743 G/C 672 G/C 1048 G 872 G 834 19.83 734 G 733 G 723 G 318 G 627 32.81 761 G 714 G 765 G 824 G 766 5.92 615 G/C 748 G 621 G/C 555 G 635 12.8Meanstrength,c<strong>as</strong>estudyCOV,c<strong>as</strong>estudy764 24.43 730 G/C 784 G 755 G 766 G 759 3.0 712 11.2Note: N: number <strong>of</strong> the specimen, Gr: grooved, w/o: without freeze-thaw cycles, FT: freeze-thaw cycles, G:failure in the grooves, G/C: mixture failure between bond and <strong>concrete</strong>. Strength in psi.However, excellent bond <strong>performance</strong> w<strong>as</strong> achieved under saturated <strong>concrete</strong> substrate,with the exception <strong>of</strong> four composite specimens that presented scattered results. The testresults for the saturated substrate samples are presented in Table 4.6 along withdescriptions <strong>of</strong> the failure modes. The four specimens with <strong>high</strong> COV were <strong>high</strong>lighted ingrey. The rest <strong>of</strong> the samples widely satisfied the range <strong>of</strong> 250 to 300 psi (1.7 to 2 MPa)at 28 days specified in the ACI 546.3R-06 for acceptable bond strength and 300 psi (2.1MPa) that (Sprinkel and Ozyildirim 2000) defined <strong>as</strong> an excellent bond. These valuesrefer to direct tensile bond. This comparison with indirect tensile strength is b<strong>as</strong>ed onresults from Momayez et al. (2005) that demonstrated the bond strength obtained with thepull-<strong>of</strong>f test (direct tensile strength) to be equal or slightly lower than that <strong>of</strong> the splittingtest (indirect tensile strength).76