E-Andrew Sindt Creative Component S11.pdf

E-Andrew Sindt Creative Component S11.pdf

E-Andrew Sindt Creative Component S11.pdf

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

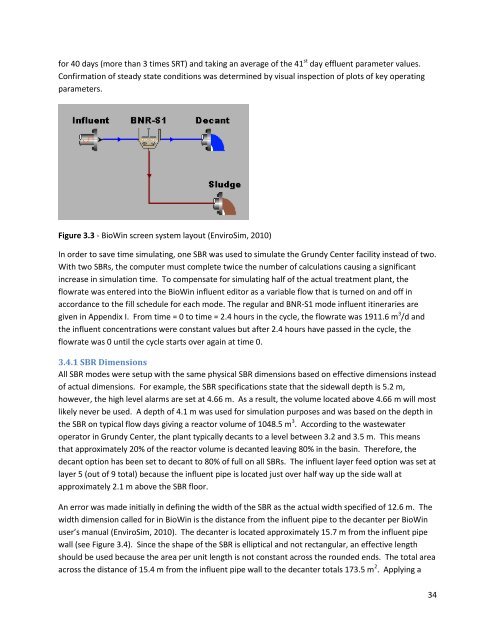

for 40 days (more than 3 times SRT) and taking an average of the 41 st day effluent parameter values.Confirmation of steady state conditions was determined by visual inspection of plots of key operatingparameters.Figure 3.3 - BioWin screen system layout (EnviroSim, 2010)In order to save time simulating, one SBR was used to simulate the Grundy Center facility instead of two.With two SBRs, the computer must complete twice the number of calculations causing a significantincrease in simulation time. To compensate for simulating half of the actual treatment plant, theflowrate was entered into the BioWin influent editor as a variable flow that is turned on and off inaccordance to the fill schedule for each mode. The regular and BNR-S1 mode influent itineraries aregiven in Appendix I. From time = 0 to time = 2.4 hours in the cycle, the flowrate was 1911.6 m 3 /d andthe influent concentrations were constant values but after 2.4 hours have passed in the cycle, theflowrate was 0 until the cycle starts over again at time 0.3.4.1 SBR DimensionsAll SBR modes were setup with the same physical SBR dimensions based on effective dimensions insteadof actual dimensions. For example, the SBR specifications state that the sidewall depth is 5.2 m,however, the high level alarms are set at 4.66 m. As a result, the volume located above 4.66 m will mostlikely never be used. A depth of 4.1 m was used for simulation purposes and was based on the depth inthe SBR on typical flow days giving a reactor volume of 1048.5 m 3 . According to the wastewateroperator in Grundy Center, the plant typically decants to a level between 3.2 and 3.5 m. This meansthat approximately 20% of the reactor volume is decanted leaving 80% in the basin. Therefore, thedecant option has been set to decant to 80% of full on all SBRs. The influent layer feed option was set atlayer 5 (out of 9 total) because the influent pipe is located just over half way up the side wall atapproximately 2.1 m above the SBR floor.An error was made initially in defining the width of the SBR as the actual width specified of 12.6 m. Thewidth dimension called for in BioWin is the distance from the influent pipe to the decanter per BioWinuser’s manual (EnviroSim, 2010). The decanter is located approximately 15.7 m from the influent pipewall (see Figure 3.4). Since the shape of the SBR is elliptical and not rectangular, an effective lengthshould be used because the area per unit length is not constant across the rounded ends. The total areaacross the distance of 15.4 m from the influent pipe wall to the decanter totals 173.5 m 2 . Applying a34