Maintenance & Inspection Guide Edge 400A Series - Johnstech

Maintenance & Inspection Guide Edge 400A Series - Johnstech

Maintenance & Inspection Guide Edge 400A Series - Johnstech

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

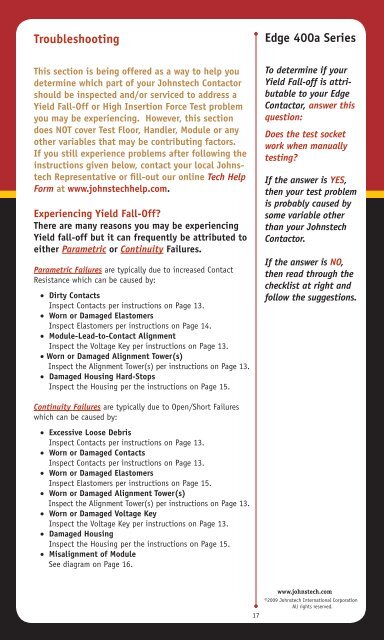

Troubleshooting<strong>Edge</strong> 400a <strong>Series</strong>This section is being offered as a way to help youdetermine which part of your <strong>Johnstech</strong> Contactorshould be inspected and/or serviced to address aYield Fall-Off or High Insertion Force Test problemyou may be experiencing. However, this sectiondoes NOT cover Test Floor, Handler, Module or anyother variables that may be contributing factors.If you still experience problems after following theinstructions given below, contact your local <strong>Johnstech</strong>Representative or fill-out our online Tech HelpForm at www.johnstechhelp.com.Experiencing Yield Fall-Off?There are many reasons you may be experiencingYield fall-off but it can frequently be attributed toeither Parametric or Continuity Failures.Parametric Failures are typically due to increased ContactResistance which can be caused by:• Dirty ContactsInspect Contacts per instructions on Page 13.• Worn or Damaged ElastomersInspect Elastomers per instructions on Page 14.• Module-Lead-to-Contact AlignmentInspect the Voltage Key per instructions on Page 13.• Worn or Damaged Alignment Tower(s)Inspect the Alignment Tower(s) per instructions on Page 13.• Damaged Housing Hard-StopsInspect the Housing per the instructions on Page 15.To determine if yourYield Fall-off is attributableto your <strong>Edge</strong>Contactor, answer thisquestion:Does the test socketwork when manuallytesting?If the answer is YES,then your test problemis probably caused bysome variable otherthan your <strong>Johnstech</strong>Contactor.If the answer is NO,then read through thechecklist at right andfollow the suggestions.Continuity Failures are typically due to Open/Short Failureswhich can be caused by:• Excessive Loose DebrisInspect Contacts per instructions on Page 13.• Worn or Damaged ContactsInspect Contacts per instructions on Page 13.• Worn or Damaged ElastomersInspect Elastomers per instructions on Page 15.• Worn or Damaged Alignment Tower(s)Inspect the Alignment Tower(s) per instructions on Page 13.• Worn or Damaged Voltage KeyInspect the Voltage Key per instructions on Page 13.• Damaged HousingInspect the Housing per the instructions on Page 15.• Misalignment of ModuleSee diagram on Page 16.17www.johnstech.com©2009 <strong>Johnstech</strong> International CorporationAll rights reserved.