MECHANISATION AUTOMATION - Esab

MECHANISATION AUTOMATION - Esab

MECHANISATION AUTOMATION - Esab

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

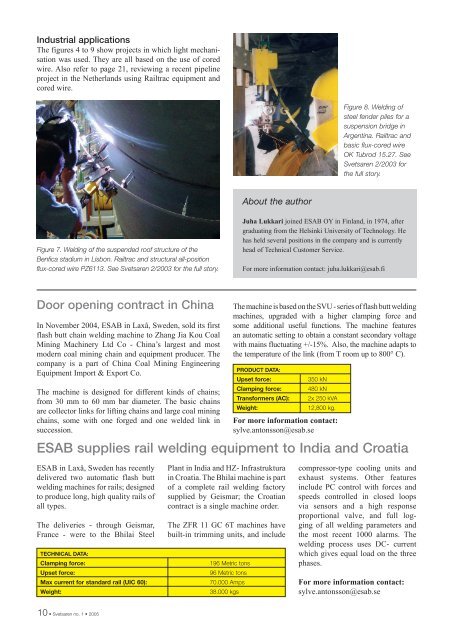

Industrial applicationsThe figures 4 to 9 show projects in which light mechanisationwas used. They are all based on the use of coredwire. Also refer to page 21, reviewing a recent pipelineproject in the Netherlands using Railtrac equipment andcored wire.Figure 8. Welding ofsteel fender piles for asuspension bridge inArgentina. Railtrac andbasic flux-cored wireOK Tubrod 15.27. SeeSvetsaren 2/2003 forthe full story.About the authorFigure 7. Welding of the suspended roof structure of theBenfica stadium in Lisbon. Railtrac and structural all-positionflux-cored wire PZ6113. See Svetsaren 2/2003 for the full story.Juha Lukkari joined ESAB OY in Finland, in 1974, aftergraduating from the Helsinki University of Technology. Hehas held several positions in the company and is currentlyhead of Technical Customer Service.For more information contact: juha.lukkari@esab.fiDoor opening contract in ChinaIn November 2004, ESAB in Laxå, Sweden, sold its firstflash butt chain welding machine to Zhang Jia Kou CoalMining Machinery Ltd Co - China’s largest and mostmodern coal mining chain and equipment producer. Thecompany is a part of China Coal Mining EngineeringEquipment Import & Export Co.The machine is designed for different kinds of chains;from 30 mm to 60 mm bar diameter. The basic chainsare collector links for lifting chains and large coal miningchains, some with one forged and one welded link insuccession.The machine is based on the SVU - series of flash butt weldingmachines, upgraded with a higher clamping force andsome additional useful functions. The machine featuresan automatic setting to obtain a constant secondary voltagewith mains fluctuating +/-15%. Also, the machine adapts tothe temperature of the link (from T room up to 800° C).PRODUCT DATA:Upset force:Clamping force:Transformers (AC):Weight:350 kN480 kN2x 250 kVA12,800 kg.For more information contact:sylve.antonsson@esab.seESAB supplies rail welding equipment to India and CroatiaESAB in Laxå, Sweden has recentlydelivered two automatic flash buttwelding machines for rails; designedto produce long, high quality rails ofall types.The deliveries - through Geismar,France - were to the Bhilai SteelTECHNICAL DATA:Clamping force:Upset force:Max current for standard rail (UIC 60):Weight:Plant in India and HZ- Infrastrukturain Croatia. The Bhilai machine is partof a complete rail welding factorysupplied by Geismar; the Croatiancontract is a single machine order.The ZFR 11 GC 6T machines havebuilt-in trimming units, and include196 Metric tons96 Metric tons70.000 Amps38.000 kgscompressor-type cooling units andexhaust systems. Other featuresinclude PC control with forces andspeeds controlled in closed loopsvia sensors and a high responseproportional valve, and full loggingof all welding parameters andthe most recent 1000 alarms. Thewelding process uses DC- currentwhich gives equal load on the threephases.For more information contact:sylve.antonsson@esab.se10 • Svetsaren no. 1 • 2005