ASPIRE Spring 11 - Aspire - The Concrete Bridge Magazine

ASPIRE Spring 11 - Aspire - The Concrete Bridge Magazine

ASPIRE Spring 11 - Aspire - The Concrete Bridge Magazine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

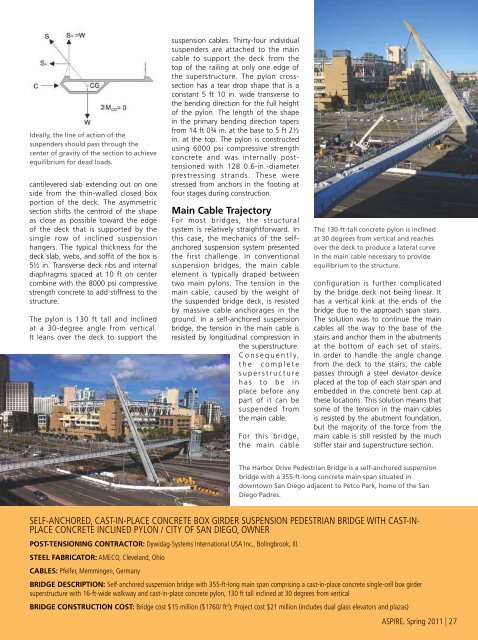

Ideally, the line of action of thesuspenders should pass through thecenter of gravity of the section to achieveequilibrium for dead loads.cantilevered slab extending out on oneside from the thin-walled closed boxportion of the deck. <strong>The</strong> asymmetricsection shifts the centroid of the shapeas close as possible toward the edgeof the deck that is supported by thesingle row of inclined suspensionhangers. <strong>The</strong> typical thickness for thedeck slab, webs, and soffit of the box is5½ in. Transverse deck ribs and internaldiaphragms spaced at 10 ft on centercombine with the 8000 psi compressivestrength concrete to add stiffness to thestructure.<strong>The</strong> pylon is 130 ft tall and inclinedat a 30-degree angle from vertical.It leans over the deck to support thesuspension cables. Thirty-four individualsuspenders are attached to the maincable to support the deck from thetop of the railing at only one edge ofthe superstructure. <strong>The</strong> pylon crosssectionhas a tear drop shape that is aconstant 5 ft 10 in. wide transverse tothe bending direction for the full heightof the pylon. <strong>The</strong> length of the shapein the primary bending direction tapersfrom 14 ft 0¾ in. at the base to 5 ft 2½in. at the top. <strong>The</strong> pylon is constructedusing 6000 psi compressive strengthconcrete and was internally posttensionedwith 128 0.6-in.-diameterprestressing strands. <strong>The</strong>se werestressed from anchors in the footing atfour stages during construction.Main Cable TrajectoryFor most bridges, the structuralsystem is relatively straightforward. Inthis case, the mechanics of the selfanchoredsuspension system presentedthe first challenge. In conventionalsuspension bridges, the main cableelement is typically draped betweentwo main pylons. <strong>The</strong> tension in themain cable, caused by the weight ofthe suspended bridge deck, is resistedby massive cable anchorages in theground. In a self-anchored suspensionbridge, the tension in the main cable isresisted by longitudinal compression inthe superstructure.Consequently,the completesuperstructurehas to be inplace before anypart of it can besuspended fromthe main cable.For this bridge,the main cable<strong>The</strong> 130-ft-tall concrete pylon is inclinedat 30 degrees from vertical and reachesover the deck to produce a lateral curvein the main cable necessary to provideequilibrium to the structure.configuration is further complicatedby the bridge deck not being linear. Ithas a vertical kink at the ends of thebridge due to the approach span stairs.<strong>The</strong> solution was to continue the maincables all the way to the base of thestairs and anchor them in the abutmentsat the bottom of each set of stairs.In order to handle the angle changefrom the deck to the stairs, the cablepasses through a steel deviator deviceplaced at the top of each stair span andembedded in the concrete bent cap atthese locations. This solution means thatsome of the tension in the main cablesis resisted by the abutment foundation,but the majority of the force from themain cable is still resisted by the muchstiffer stair and superstructure section.<strong>The</strong> Harbor Drive Pedestrian <strong>Bridge</strong> is a self-anchored suspensionbridge with a 355-ft-long concrete main span situated indowntown San Diego adjacent to Petco Park, home of the SanDiego Padres.SELF-ANCHORED, CAST-IN-PLACE CONCRETE BOX GIRDER SUSPENSION PEDESTRIAN BRIDGE WITH CAST-IN-PLACE CONCRETE INCLINED PYLON / CITY OF SAN DIEGO, OWNERpost-tensioning contractor: Dywidag-Systems International USA Inc., Bolingbrook, Ill.steel FABRICATOR: AMECO, Cleveland, Ohiocables: Pfeifer, Memmingen, Germanybridge description: Self-anchored suspension bridge with 355-ft-long main span comprising a cast-in-place concrete single-cell box girdersuperstructure with 16-ft-wide walkway and cast-in-place concrete pylon, 130 ft tall inclined at 30 degrees from vertical<strong>Bridge</strong> Construction Cost: <strong>Bridge</strong> cost $15 million ($1760/ ft 2 ); Project cost $21 million (includes dual glass elevators and plazas)<strong>ASPIRE</strong>, <strong>Spring</strong> 20<strong>11</strong> | 27