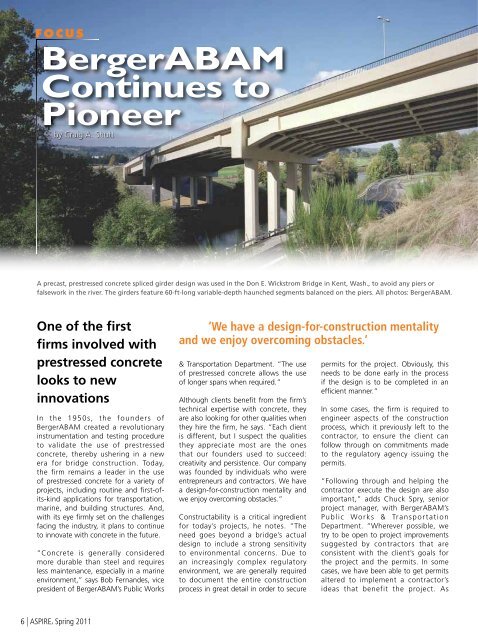

FOCUSBergerABAMContinues toPioneerby Craig A. ShuttA precast, prestressed concrete spliced girder design was used in the Don E. Wickstrom <strong>Bridge</strong> in Kent, Wash., to avoid any piers orfalsework in the river. <strong>The</strong> girders feature 60-ft-long variable-depth haunched segments balanced on the piers. All photos: BergerABAM.One of the firstfirms involved withprestressed concretelooks to newinnovationsIn the 1950s, the founders ofBergerABAM created a revolutionaryinstrumentation and testing procedureto validate the use of prestressedconcrete, thereby ushering in a newera for bridge construction. Today,the firm remains a leader in the useof prestressed concrete for a variety ofprojects, including routine and first-ofits-kindapplications for transportation,marine, and building structures. And,with its eye firmly set on the challengesfacing the industry, it plans to continueto innovate with concrete in the future.“<strong>Concrete</strong> is generally consideredmore durable than steel and requiresless maintenance, especially in a marineenvironment,” says Bob Fernandes, vicepresident of BergerABAM’s Public Works‘We have a design-for-construction mentalityand we enjoy overcoming obstacles.’& Transportation Department. “<strong>The</strong> useof prestressed concrete allows the useof longer spans when required.”Although clients benefit from the firm’stechnical expertise with concrete, theyare also looking for other qualities whenthey hire the firm, he says. “Each clientis different, but I suspect the qualitiesthey appreciate most are the onesthat our founders used to succeed:creativity and persistence. Our companywas founded by individuals who wereentrepreneurs and contractors. We havea design-for-construction mentality andwe enjoy overcoming obstacles.”Constructability is a critical ingredientfor today’s projects, he notes. “<strong>The</strong>need goes beyond a bridge’s actualdesign to include a strong sensitivityto environmental concerns. Due toan increasingly complex regulatoryenvironment, we are generally requiredto document the entire constructionprocess in great detail in order to securepermits for the project. Obviously, thisneeds to be done early in the processif the design is to be completed in anefficient manner.”In some cases, the firm is required toengineer aspects of the constructionprocess, which it previously left to thecontractor, to ensure the client canfollow through on commitments madeto the regulatory agency issuing thepermits.“Following through and helping thecontractor execute the design are alsoimportant,” adds Chuck Spry, seniorproject manager, with BergerABAM’sPublic Works & TransportationDepartment. “Wherever possible, wetry to be open to project improvementssuggested by contractors that areconsistent with the client’s goals forthe project and the permits. In somecases, we have been able to get permitsaltered to implement a contractor’sideas that benefit the project. As6 | <strong>ASPIRE</strong>, <strong>Spring</strong> 20<strong>11</strong>

‘As projectsbecome more complex. . . we need goodrelationships with thecontractor.’projects become more complex andhave more requirements, we need goodrelationships with the contractor toensure the design becomes reality.”Devising designs that meet all theowners’ needs has been foremost sincethe firm’s inception. BergerABAM’sheritage dates to 1951. <strong>Concrete</strong>Engineering Co., which wouldbecome <strong>Concrete</strong> Technology Corp.,was founded by brothers Art andTom Anderson. Using his innovativeinstrumentation (strain gauge) andtesting program, Art proved prestressedconcrete was reliable to early skepticson the Walnut Lane <strong>Bridge</strong> inPhiladelphia. Built during 1949 and1950, the bridge became famous forits first use of prestressed concrete ina structure built in the United States,leading to many more bridges using thisinnovative technique.Art’s work ultimately led to the foundingof Anderson, Birkeland, Anderson andMast, shortened to ABAM Engineersin 1966. It became an affiliate of <strong>The</strong>Louis Berger Group Inc. in the late1980s, creating BergerABAM. “<strong>The</strong>firm essentially was founded due to theWalnut Lane <strong>Bridge</strong>, and bridges havebeen a major focus of our work eversince,” says Bob Mast, senior principaland the last remaining namesake<strong>The</strong> Elwha River <strong>Bridge</strong> in Clallam County,Wash., combines a cast-in-place segmentalconcrete bridge with a precast concretepedestrian bridge hung beneath thestructure. <strong>The</strong> three-span bridge separatesvehicle traffic from pedestrians using theOlympic Discovery Trail.partner. (For more on the company’shistory, see the sidebar.)Long Spans Reduce ImpactLong spans are becoming more popularto reduce environmental impact andto simplify complex geometries atinterchanges, where ramps andjunctions create traffic congestion. Thishas been aided by the Washington StateDepartment of Transportation (WSDOT)devising its own precast concrete girdershapes, which it encourages designersto use.Longer spans and more slendergirders are heavier and more difficultto handle than shorter shallowergirders. This challenge has required theindustry to develop new engineeringpractices. Mast has added to thatbody of knowledge, having workedat BergerABAM for over 50 years,including serving as president from1972 to 1986. Among his contributionshas been intensive study to developstandards and procedures for handlinglong precast concrete beams to ensuretheir stability during transport anderection.“<strong>The</strong> ways that long and heavycomponents are shipped have reallychanged, which has had an impact onwhat’s possible for bridge designs,”Mast says. “<strong>The</strong>re is much moreavailability of specialized equipmentto ensure that large, complex piecescan be handled easily. When I began,the absolute limit for transportingcomponents on the highway was 60tons. Now it’s double that, and we’repushing 200-ft for long plant-madebeams.”An example of the creative use ofprecast concrete to construct longerspans is the Don E. Wickstrom <strong>Bridge</strong>,a precast concrete spliced-girder design,created for the City of Kent, Wash. Akey reason for selecting the precastconcrete option was that the city didnot want any piers, or even falsework,to impact the Green River. <strong>The</strong> site alsodid not have good access.<strong>The</strong> design allowed the deliveryand erection of precast concrete inreasonable sizes so they could be siteassembledinto the final structure. <strong>The</strong>bridge also required a curving alignmenton a 9% grade, adding challenges. <strong>The</strong>three-span bridge includes a 183-ft-longmain span using 7-ft-deep WSDOTsuper girders.<strong>The</strong> firm also uses cast-in-place concreteto build slender and longer spans. Acreative example is the State Route 509(SR 509) <strong>Bridge</strong> that spans I-705 and theOn the State Route 509 interchange that spans I-705 and the BNSF Railway track in Tacoma, Wash., BergerABAM created a curving, elevatedsingle point urban interchange, the first in Washington state and one of the first in the country. <strong>The</strong> structure features cast-in-place, posttensionedconcrete box girders with variable-depth webs.<strong>ASPIRE</strong>, <strong>Spring</strong> 20<strong>11</strong> | 7