ASPIRE Spring 11 - Aspire - The Concrete Bridge Magazine

ASPIRE Spring 11 - Aspire - The Concrete Bridge Magazine

ASPIRE Spring 11 - Aspire - The Concrete Bridge Magazine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

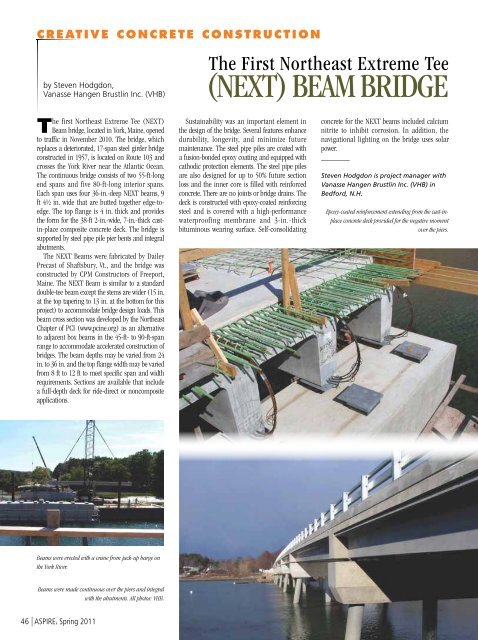

CREATIVE CONCRETE CONSTRUCTIONby Steven Hodgdon,Vanasse Hangen Brustlin Inc. (VHB)<strong>The</strong> First Northeast Extreme Tee(NEXT) Beam <strong>Bridge</strong><strong>The</strong> first Northeast Extreme Tee (NEXT)Beam bridge, located in York, Maine, openedto traffic in November 2010. <strong>The</strong> bridge, whichreplaces a deteriorated, 17-span steel girder bridgeconstructed in 1957, is located on Route 103 andcrosses the York River near the Atlantic Ocean.<strong>The</strong> continuous bridge consists of two 55-ft-longend spans and five 80-ft-long interior spans.Each span uses four 36-in.-deep NEXT beams, 9ft 4½ in. wide that are butted together edge-toedge.<strong>The</strong> top flange is 4 in. thick and providesthe form for the 38-ft 2-in.-wide, 7-in.-thick castin-placecomposite concrete deck. <strong>The</strong> bridge issupported by steel pipe pile pier bents and integralabutments.<strong>The</strong> NEXT Beams were fabricated by DaileyPrecast of Shaftsbury, Vt., and the bridge wasconstructed by CPM Constructors of Freeport,Maine. <strong>The</strong> NEXT Beam is similar to a standarddouble-tee beam except the stems are wider (15 in.at the top tapering to 13 in. at the bottom for thisproject) to accommodate bridge design loads. Thisbeam cross section was developed by the NortheastChapter of PCI (www.pcine.org) as an alternativeto adjacent box beams in the 45-ft- to 90-ft-spanrange to accommodate accelerated construction ofbridges. <strong>The</strong> beam depths may be varied from 24in. to 36 in. and the top flange width may be variedfrom 8 ft to 12 ft to meet specific span and widthrequirements. Sections are available that includea full-depth deck for ride-direct or noncompositeapplications.Sustainability was an important element inthe design of the bridge. Several features enhancedurability, longevity, and minimize futuremaintenance. <strong>The</strong> steel pipe piles are coated witha fusion-bonded epoxy coating and equipped withcathodic protection elements. <strong>The</strong> steel pipe pilesare also designed for up to 50% future sectionloss and the inner core is filled with reinforcedconcrete. <strong>The</strong>re are no joints or bridge drains. <strong>The</strong>deck is constructed with epoxy-coated reinforcingsteel and is covered with a high-performancewaterproofing membrane and 3-in.-thickbituminous wearing surface. Self-consolidatingconcrete for the NEXT beams included calciumnitrite to inhibit corrosion. In addition, thenavigational lighting on the bridge uses solarpower._______Steven Hodgdon is project manager withVanasse Hangen Brustlin Inc. (VHB) inBedford, N.H.Epoxy-coated reinforcement extending from the cast-inplaceconcrete deck provided for the negative momentover the piers.Beams were erected with a crane from jack-up barge onthe York River.Beams were made continuous over the piers and integralwith the abutments. All photos: VHB.46 | <strong>ASPIRE</strong>, <strong>Spring</strong> 20<strong>11</strong>