ASPIRE Spring 11 - Aspire - The Concrete Bridge Magazine

ASPIRE Spring 11 - Aspire - The Concrete Bridge Magazine

ASPIRE Spring 11 - Aspire - The Concrete Bridge Magazine

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

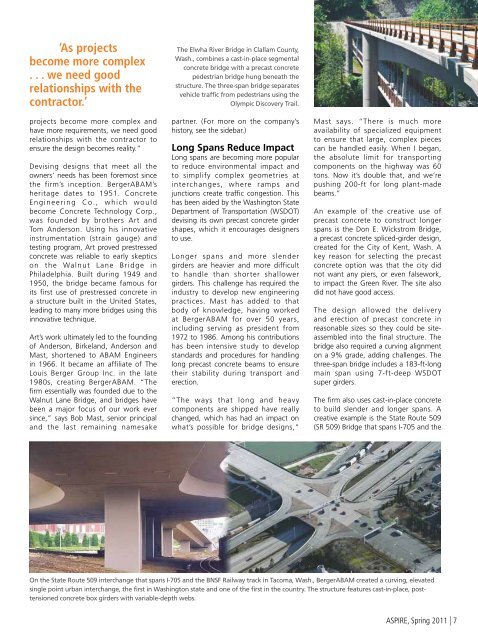

‘As projectsbecome more complex. . . we need goodrelationships with thecontractor.’projects become more complex andhave more requirements, we need goodrelationships with the contractor toensure the design becomes reality.”Devising designs that meet all theowners’ needs has been foremost sincethe firm’s inception. BergerABAM’sheritage dates to 1951. <strong>Concrete</strong>Engineering Co., which wouldbecome <strong>Concrete</strong> Technology Corp.,was founded by brothers Art andTom Anderson. Using his innovativeinstrumentation (strain gauge) andtesting program, Art proved prestressedconcrete was reliable to early skepticson the Walnut Lane <strong>Bridge</strong> inPhiladelphia. Built during 1949 and1950, the bridge became famous forits first use of prestressed concrete ina structure built in the United States,leading to many more bridges using thisinnovative technique.Art’s work ultimately led to the foundingof Anderson, Birkeland, Anderson andMast, shortened to ABAM Engineersin 1966. It became an affiliate of <strong>The</strong>Louis Berger Group Inc. in the late1980s, creating BergerABAM. “<strong>The</strong>firm essentially was founded due to theWalnut Lane <strong>Bridge</strong>, and bridges havebeen a major focus of our work eversince,” says Bob Mast, senior principaland the last remaining namesake<strong>The</strong> Elwha River <strong>Bridge</strong> in Clallam County,Wash., combines a cast-in-place segmentalconcrete bridge with a precast concretepedestrian bridge hung beneath thestructure. <strong>The</strong> three-span bridge separatesvehicle traffic from pedestrians using theOlympic Discovery Trail.partner. (For more on the company’shistory, see the sidebar.)Long Spans Reduce ImpactLong spans are becoming more popularto reduce environmental impact andto simplify complex geometries atinterchanges, where ramps andjunctions create traffic congestion. Thishas been aided by the Washington StateDepartment of Transportation (WSDOT)devising its own precast concrete girdershapes, which it encourages designersto use.Longer spans and more slendergirders are heavier and more difficultto handle than shorter shallowergirders. This challenge has required theindustry to develop new engineeringpractices. Mast has added to thatbody of knowledge, having workedat BergerABAM for over 50 years,including serving as president from1972 to 1986. Among his contributionshas been intensive study to developstandards and procedures for handlinglong precast concrete beams to ensuretheir stability during transport anderection.“<strong>The</strong> ways that long and heavycomponents are shipped have reallychanged, which has had an impact onwhat’s possible for bridge designs,”Mast says. “<strong>The</strong>re is much moreavailability of specialized equipmentto ensure that large, complex piecescan be handled easily. When I began,the absolute limit for transportingcomponents on the highway was 60tons. Now it’s double that, and we’repushing 200-ft for long plant-madebeams.”An example of the creative use ofprecast concrete to construct longerspans is the Don E. Wickstrom <strong>Bridge</strong>,a precast concrete spliced-girder design,created for the City of Kent, Wash. Akey reason for selecting the precastconcrete option was that the city didnot want any piers, or even falsework,to impact the Green River. <strong>The</strong> site alsodid not have good access.<strong>The</strong> design allowed the deliveryand erection of precast concrete inreasonable sizes so they could be siteassembledinto the final structure. <strong>The</strong>bridge also required a curving alignmenton a 9% grade, adding challenges. <strong>The</strong>three-span bridge includes a 183-ft-longmain span using 7-ft-deep WSDOTsuper girders.<strong>The</strong> firm also uses cast-in-place concreteto build slender and longer spans. Acreative example is the State Route 509(SR 509) <strong>Bridge</strong> that spans I-705 and theOn the State Route 509 interchange that spans I-705 and the BNSF Railway track in Tacoma, Wash., BergerABAM created a curving, elevatedsingle point urban interchange, the first in Washington state and one of the first in the country. <strong>The</strong> structure features cast-in-place, posttensionedconcrete box girders with variable-depth webs.<strong>ASPIRE</strong>, <strong>Spring</strong> 20<strong>11</strong> | 7