Parallel EU projects – Parallella EU-projekt – Parallele EU-Projekte – Projets parallèles avec l’UEEU6. HIPERWHEELHIPERWHEEL – Development of an innovative high performancerailway wheelsetEntwicklung eines innovativen leistungsstarken RadsatzesDéveloppement d’un essieu monté innovent à haute performanceProject leaderProfessor Roger Lundén,Applied MechanicsCo-workersDocent Jens Nielsen,Applied MechanicsDr Anders Ekberg,Assistant Professor,Applied MechanicsPeriod 2000-04-01 – <strong>2003</strong>-06-30(– 2004-03-31)Budget EU keuro 141Budget <strong>CHARMEC</strong> Stage 3: keuro 1200For photos of project leader and co-workers, see pages19, 40 and 49The hiperwheel project of the Fifth Framework Programmecomprises a total of 280 man-months, and it hasa budgeted project cost of keuro 3690 and a budgetedeu funding of keuro 1979. Chalmers/charmec’s commitmentto hiperwheel is 13 man-months. Partners inthe project are Centro Ricerche Fiat (Italy), ChalmersApplied Mechanics/charmec (Sweden), Trenitalia(Italy), Fraunhofer-Institut für Betriebsfestigkeit lbf(Germany), Lucchini Sidermeccanica (Italy), MechanicalDynamics Italy (Italy), Otto Fuchs Metallwerke(Germany), Politecnico di Milano (Italy), Departmentof Mechanical Engineering at University of Sheffield(uk) and Valdunes (France). The duration of thehiperwheel project is 48 months and it is co-ordinatedby Centro Ricerche Fiat.Outstanding safety, lower weight, longer maintenanceintervals and less noise radiation are properties of futurewheelsets that the hiperwheel project aims at attaining.Mechanisms of damage such as rolling contact fatigue ofthe tread and fretting fatigue in the shrink-fit or press-fitbetween wheel and axle are to be considered. charmec’smain responsibility in the eu6 project, in collaborationwith the University of Sheffield, is to study damagemechanisms and to act as task leader for “Numericalprocedure for nvh analysis” (Work Package wp5).Meetings with our partners have been held in Darmstadt(Germany), Lovere, Milano and Orbassano (Italy),Meinerzhagen (Germany), Sheffield (uk), Valencia(Spain) and Gothenburg.Our work in wp3 “Damage mechanisms acting on thewheelset and database for fatigue life predictions” hasbeen completed. We have developed an “engineering”model for analysis of rolling contact fatigue of railwaywheels. It is based on three fatigue indices and is coupledto models for simulation of the running dynamics ofbogie and wheelsets, see further information on fierceunder project mu9. In addition our work in wp4 “caebasedprocedure for wheelset durability assessments”has been finalized.A numerical procedure for multidisciplinary optimizationof wheelsets, based on a parametric fe model andon statistical trial planning and automated computerprogramexecution, has been developed by us in wp5in collaboration with the company Ingemansson Technologyin Gothenburg and Jönköping. The commercialprograms patran, nastran, matlab and twins havehere been combined for calculation of weight, modalparameters, fatigue stresses and noise radiation. lms/optimus has been used to execute and monitor the othersoftware, visualize the space of the design parametersand search for an optimum design. The aim is to find adesign that minimizes both the dynamic contributionto the contact forces between wheel and rail (due to areduced unsprung mass) and noise radiation (due to anoptimized form of the wheel cross-section combined witha surface layer of damping applied to the web), whilethe wheel’s fatigue strength is maintained. Examples ofdesign variables are wheel radius, web thickness, lateraloffset between ring and hub, transfer radii between ring,web and hub, and thickness of damping layer.Our work on fretting fatigue of railway axles in thecontact zone with the wheel hub (press fit or shrink fit)is in its closing phase, see below.Anders Ekberg, Elena Kabo and Hans Andersson: Predictingrolling contact fatigue of railway wheels (see under project MU9)Mauro Cavalletti, Anders Ekberg, Alan Facchinetti, GiampaoloMancini and Maurizio Stanca: Prediction of rail vehicle missionloads and RCF damage by multibody modelling, Proceedings1st MSC.ADAMS European User Conference, London (UK)November 2002, 12 pp on CDAnders Ekberg, Elena Kabo and Hans Andersson: An engineeringmodel for prediction of rolling contact fatigue of railwaywheels (see under project MU9)Anders Ekberg: Predicting fretting fatigue of railway wheel/axle assemblies – a state-of-the-art survey, Chalmers AppliedMechanics, Gothenburg <strong>2003</strong> (in progress)Anders Ekberg: Numerical prediction of fretting of railwayaxles, Proceedings International Seminar on Railway Axles atImperial College, London (UK) September <strong>2003</strong>, 37 pp on CD55

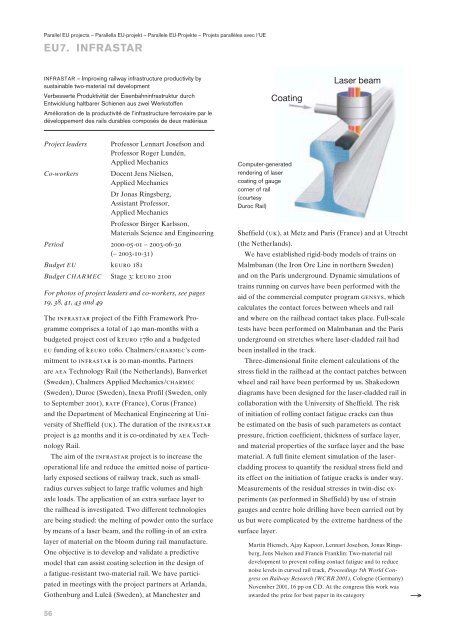

Parallel EU projects – Parallella EU-projekt – Parallele EU-Projekte – Projets parallèles avec l’UEEU7. INFRASTARINFRASTAR – Improving railway infrastructure productivity bysustainable two-material rail developmentVerbesserte Produktivität der Eisenbahninfrastruktur durchEntwicklung haltbarer Schienen aus zwei WerkstoffenAmélioration de la productivité de l’infrastructure ferroviaire par ledéveloppement des rails durables composés de deux matériauxCoatingLaser beamProject leadersProfessor Lennart Josefson andProfessor Roger Lundén,Applied MechanicsCo-workers Docent Jens Nielsen,Applied MechanicsDr Jonas Ringsberg,Assistant Professor,Applied MechanicsProfessor Birger Karlsson,Materials Science and EngineeringPeriod 2000-05-01 – <strong>2003</strong>-06-30(– <strong>2003</strong>-10-31)Budget EU keuro 181Budget <strong>CHARMEC</strong> Stage 3: keuro 2100For photos of project leaders and co-workers, see pages19, 38, 41, 43 and 49The infrastar project of the Fifth Framework Programmecomprises a total of 140 man-months with abudgeted project cost of keuro 1780 and a budgetedeu funding of keuro 1080. Chalmers/charmec’s commitmentto infrastar is 20 man-months. Partnersare aea Technology Rail (the Netherlands), Banverket(Sweden), Chalmers Applied Mechanics/charmec(Sweden), Duroc (Sweden), Inexa Profil (Sweden, onlyto September 2001), ratp (France), Corus (France)and the Department of Mechanical Engineering at Universityof Sheffield (uk). The duration of the infrastarproject is 42 months and it is co-ordinated by aea TechnologyRail.The aim of the infrastar project is to increase theoperational life and reduce the emitted noise of particularlyexposed sections of railway track, such as smallradiuscurves subject to large traffic volumes and highaxle loads. The application of an extra surface layer tothe railhead is investigated. Two different technologiesare being studied: the melting of powder onto the surfaceby means of a laser beam, and the rolling-in of an extralayer of material on the bloom during rail manufacture.One objective is to develop and validate a predictivemodel that can assist coating selection in the design ofa fatigue-resistant two-material rail. We have participatedin meetings with the project partners at Arlanda,Gothenburg and Luleå (Sweden), at Manchester andComputer-generatedrendering of lasercoating of gaugecorner of rail(courtesyDuroc Rail)Sheffield (uk), at Metz and Paris (France) and at Utrecht(the Netherlands).We have established rigid-body models of trains onMalmbanan (the Iron Ore Line in northern Sweden)and on the Paris underground. Dynamic simulations oftrains running on curves have been performed with theaid of the commercial computer program gensys, whichcalculates the contact forces between wheels and railand where on the railhead contact takes place. Full-scaletests have been performed on Malmbanan and the Parisunderground on stretches where laser-cladded rail hadbeen installed in the track.Three-dimensional finite element calculations of thestress field in the railhead at the contact patches betweenwheel and rail have been performed by us. Shakedowndiagrams have been designed for the laser-cladded rail incollaboration with the University of Sheffield. The riskof initiation of rolling contact fatigue cracks can thusbe estimated on the basis of such parameters as contactpressure, friction coefficient, thickness of surface layer,and material properties of the surface layer and the basematerial. A full finite element simulation of the lasercladdingprocess to quantify the residual stress field andits effect on the initiation of fatigue cracks is under way.Measurements of the residual stresses in twin-disc experiments(as performed in Sheffield) by use of straingauges and centre hole drilling have been carried out byus but were complicated by the extreme hardness of thesurface layer.Martin Hiensch, Ajay Kapoor, Lennart Josefson, Jonas Ringsberg,Jens Nielsen and Francis Franklin: Two-material raildevelopment to prevent rolling contact fatigue and to reducenoise levels in curved rail track, Proceedings 5th World Congresson Railway Research (WCRR 2001), Cologne (Germany)November 2001, 16 pp on CD. At the congress this work wasawarded the prize for best paper in its category→56