- Page 1: RTrailer RefrigerationEVAPORATORTXV

- Page 4 and 5: TABLE OF CONTENTS (Continued)PARAGR

- Page 6 and 7: PARAGRAPH NUMBERTABLE OF CONTENTS (

- Page 8 and 9: TABLE OF CONTENTS (Continued)PARAGR

- Page 10 and 11: TABLE OF CONTENTS (Continued)PARAGR

- Page 13 and 14: LIST OF ILLUSTRATIONSFIGURE NUMBERP

- Page 15 and 16: SECTION 1SAFETY PRECAUTIONS1.1 SAFE

- Page 17 and 18: WARNINGRelieve internal pressure of

- Page 19 and 20: 1.3 SAFETY DECALS1--5 62-11039

- Page 21 and 22: 9SECTION 2UNIT DESCRIPTION2.1 INTRO

- Page 23 and 24: 91918117161514234567 8 9101112131.2

- Page 25 and 26: 914215121312311410867591.2.Evaporat

- Page 27 and 28: 92.3 CONDENSING SECTIONThe condensi

- Page 29 and 30: 94562 371111081291314151.2.Solenoid

- Page 31 and 32: f. Supply Air Temperature Sensor (1

- Page 33 and 34: 9PC CARD FAULT LED(RED)QC5 (NOTUSED

- Page 35 and 36: 9DOOR CLOSED13245612111.2.Compartme

- Page 37 and 38: Key DescriptionsMANUALDEFROSTALARM

- Page 39: 2.8.3 Out of Range AlarmThe Out Of

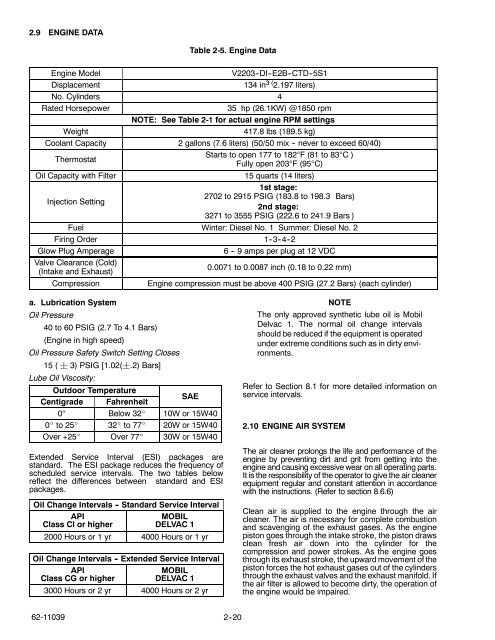

- Page 43 and 44: 2.14 COMPONENT RESISTANCE & CURRENT

- Page 45 and 46: 9LSV3EXTERNALEQUALIZERTXVBULBTXVREM

- Page 47 and 48: 9LSV3EXTERNALEQUALIZERTXVBULBTXVREM

- Page 49 and 50: 9LSV3EXTERNALEQUALIZERTXVBULBTXVREM

- Page 51 and 52: 3.2 STARTING UNIT - ENGINE/ROAD OPE

- Page 53 and 54: NOTEThe unit is equipped with autom

- Page 55 and 56: 3.5 PRETRIP1. Place RS in “START/

- Page 57 and 58: PRETRIP (Continued)Test 4 - Tempera

- Page 59 and 60: 3.7 START -STOP OPERATION - ENGINE/

- Page 61 and 62: 3.9 SLEEP MODE ONHEATCOOL DEFROST A

- Page 63 and 64: SLEEP MODE ON (Continued)No further

- Page 65 and 66: 3.12 TRIP STARTHEAT COOL DEFROST AL

- Page 67 and 68: 3.14 VIEW INACTIVE ALARMSHEAT COOL

- Page 69 and 70: **Table 3-1. UNIT DATA* Also appear

- Page 71 and 72: *+*Table 3-1. UNIT DATA* Also appea

- Page 73 and 74: 3.17 FUNCTIONAL CHANGE (PARAMETERS)

- Page 75 and 76: FUNCTIONALPARAMETERFROZEN SHUT-DOWN

- Page 77 and 78: FUNCTIONALPARAMETERS RUN PRETRIPAT

- Page 79 and 80: 3.19 STOPPING UNITWARNINGAlways pla

- Page 81 and 82: DATA RECORDING (CONTINUED)Time Inte

- Page 83 and 84: a. Changing IntelliSets - With “=

- Page 85 and 86: 3.21.2Remote Control Panel109812345

- Page 87 and 88: c.Changing Setpoint with Remote Con

- Page 89 and 90: SECTION 4TEMPERATURE CONTROL4.1 SYS

- Page 91 and 92:

4.2.2 A restart will be initiated w

- Page 93 and 94:

4.4.2 PULSE COOL MODEWhen Frozen Co

- Page 95 and 96:

4.4.5 HEAT MODEFor both 2 and 3 Com

- Page 97 and 98:

HTCONs may be energized at the same

- Page 99 and 100:

Range Lock 1 & 2Range2issetfor0° t

- Page 101 and 102:

d. ProductShield: WinterWhen the un

- Page 103 and 104:

RISING BOXTEMPERATURE+2.3_F (+1.3_C

- Page 105 and 106:

4.7.2 Unloader Control OverridesWit

- Page 107 and 108:

4.7.3 Suction Pressure OperationAt

- Page 109 and 110:

Some of the things that you may wan

- Page 111 and 112:

CONFIGURATION SELECTIONS DESCRIPTIO

- Page 113 and 114:

CONFIGURATION SELECTIONS DESCRIPTIO

- Page 115 and 116:

CONFIGURATION SELECTIONS DESCRIPTIO

- Page 117 and 118:

CONFIGURATION SELECTIONS DESCRIPTIO

- Page 119 and 120:

5.2.2 Component Test ModeNOTETo ent

- Page 121 and 122:

5.2.3 Service ModeCAUTIONService Mo

- Page 123 and 124:

5.4 INSTALLING NEW SOFTWARE5.4.1 Us

- Page 125 and 126:

5.5 SETTING PM (PREVENTATIVE MAINTE

- Page 127 and 128:

5.6.2 Microprocessor SetupNOTEBefor

- Page 129 and 130:

5.6.7 Configuration/IntelliSet Card

- Page 131 and 132:

MessageCHECK FUEL LEVELCONFIG ERROR

- Page 133 and 134:

MessagePRESS = TO MARK TRIP STARTPR

- Page 135 and 136:

SECTION 7ALARM TROUBLESHOOTING7.1 I

- Page 137 and 138:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 139 and 140:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 141 and 142:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 143 and 144:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 145 and 146:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 147 and 148:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 149 and 150:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 151 and 152:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 153 and 154:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 155 and 156:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 157 and 158:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 159 and 160:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 161 and 162:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 163 and 164:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 165 and 166:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 167 and 168:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 169 and 170:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 171 and 172:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 173 and 174:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 175 and 176:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 177 and 178:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 179 and 180:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 181 and 182:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 183 and 184:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 185 and 186:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 187 and 188:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 189 and 190:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 191 and 192:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 193 and 194:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 195 and 196:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 197 and 198:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 199 and 200:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 201 and 202:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 203 and 204:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 205 and 206:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 207 and 208:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 209 and 210:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 211 and 212:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 213 and 214:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 215 and 216:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 217 and 218:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 219 and 220:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 221 and 222:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 223 and 224:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 225 and 226:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 227 and 228:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 229 and 230:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 231 and 232:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 233 and 234:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 235 and 236:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 237 and 238:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 239 and 240:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 241 and 242:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 243 and 244:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 245 and 246:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 247 and 248:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 249 and 250:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 251 and 252:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 253 and 254:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 255 and 256:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 257 and 258:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 259 and 260:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 261 and 262:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 263 and 264:

AlarmNO.Steps ALARM / CAUSE CORRECT

- Page 265 and 266:

SECTION 8SERVICEWARNINGWhen perform

- Page 267 and 268:

e. Oil Change IntervalsOil TypePetr

- Page 269 and 270:

8.4 SERVICING FUEL PUMP8.4.1 Mechan

- Page 271 and 272:

8.6 ENGINE SERVICE AND COMPONENTS8.

- Page 273 and 274:

8.6.5 Servicing The Speed Control S

- Page 275 and 276:

8.7 EVAPORATOR HEATERS8.7.1 Descrip

- Page 277 and 278:

8.9 GENERATOR8.9.1 DescriptionDrive

- Page 279 and 280:

13.CAUTIONThe mica shim must be use

- Page 281 and 282:

a. Install two dowel pins (CTD P/N

- Page 283 and 284:

8.11 PUMPING UNIT DOWN OR REMOVING

- Page 285 and 286:

161591413812 111047312561.2.Refrige

- Page 287 and 288:

8.15 COMPRESSOR - MODEL 06DWARNINGW

- Page 289 and 290:

1. Push pistons from the inside of

- Page 291 and 292:

k. Start unit and check unloader op

- Page 293 and 294:

8.18.2 EVXV coil (Unipolar design)O

- Page 295 and 296:

8.20.2 Checking High Pressure Switc

- Page 297 and 298:

8.21.3 Replacing Compressor Dischar

- Page 299 and 300:

OPENWinding #1 Winding #21A 1B 2A 2

- Page 301 and 302:

8.25.2 Electronic Defrost TimerRefe

- Page 303 and 304:

Table 8-9. Sensor Resistance (CDT)

- Page 305 and 306:

Temperature Pressure Temperature Pr

- Page 307 and 308:

INDICATION/TROUBLE9.1.2 Engine Star

- Page 309 and 310:

INDICATION/TROUBLE9.2 BATTERY CHARG

- Page 311 and 312:

INDICATION/TROUBLE9.4 REFRIGERATION

- Page 313 and 314:

INDICATION/TROUBLEPOSSIBLE CAUSESRE

- Page 315 and 316:

SECTION 10WIRINGPlugs used with Sch

- Page 317 and 318:

4MP 5MP 6MPComponent Terminal Compo

- Page 319 and 320:

ADVANCE MICRO DISPLAY HARNESS CONNE

- Page 321 and 322:

0--

- Page 323 and 324:

EElectrical Data, 2--22Electronic E

- Page 325:

North AmericaCarrier Transicold700