Corral Petroleum Holdings AB (publ) Business Update ... - Preem

Corral Petroleum Holdings AB (publ) Business Update ... - Preem

Corral Petroleum Holdings AB (publ) Business Update ... - Preem

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

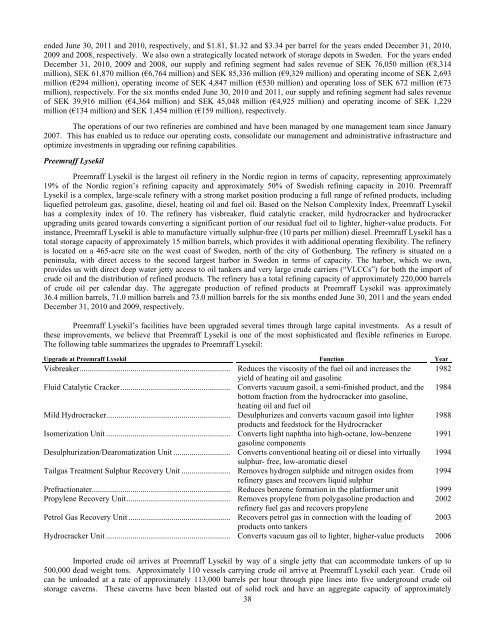

ended June 30, 2011 and 2010, respectively, and $1.81, $1.32 and $3.34 per barrel for the years ended December 31, 2010,2009 and 2008, respectively. We also own a strategically located network of storage depots in Sweden. For the years endedDecember 31, 2010, 2009 and 2008, our supply and refining segment had sales revenue of SEK 76,050 million (€8,314million), SEK 61,870 million (€6,764 million) and SEK 85,336 million (€9,329 million) and operating income of SEK 2,693million (€294 million), operating income of SEK 4,847 million (€530 million) and operating loss of SEK 672 million (€73million), respectively. For the six months ended June 30, 2010 and 2011, our supply and refining segment had sales revenueof SEK 39,916 million (€4,364 million) and SEK 45,048 million (€4,925 million) and operating income of SEK 1,229million (€134 million) and SEK 1,454 million (€159 million), respectively.The operations of our two refineries are combined and have been managed by one management team since January2007. This has enabled us to reduce our operating costs, consolidate our management and administrative infrastructure andoptimize investments in upgrading our refining capabilities.<strong>Preem</strong>raff Lysekil<strong>Preem</strong>raff Lysekil is the largest oil refinery in the Nordic region in terms of capacity, representing approximately19% of the Nordic region’s refining capacity and approximately 50% of Swedish refining capacity in 2010. <strong>Preem</strong>raffLysekil is a complex, large-scale refinery with a strong market position producing a full range of refined products, includingliquefied petroleum gas, gasoline, diesel, heating oil and fuel oil. Based on the Nelson Complexity Index, <strong>Preem</strong>raff Lysekilhas a complexity index of 10. The refinery has visbreaker, fluid catalytic cracker, mild hydrocracker and hydrocrackerupgrading units geared towards converting a significant portion of our residual fuel oil to lighter, higher-value products. Forinstance, <strong>Preem</strong>raff Lysekil is able to manufacture virtually sulphur-free (10 parts per million) diesel. <strong>Preem</strong>raff Lysekil has atotal storage capacity of approximately 15 million barrels, which provides it with additional operating flexibility. The refineryis located on a 465-acre site on the west coast of Sweden, north of the city of Gothenburg. The refinery is situated on apeninsula, with direct access to the second largest harbor in Sweden in terms of capacity. The harbor, which we own,provides us with direct deep water jetty access to oil tankers and very large crude carriers (“VLCCs”) for both the import ofcrude oil and the distribution of refined products. The refinery has a total refining capacity of approximately 220,000 barrelsof crude oil per calendar day. The aggregate production of refined products at <strong>Preem</strong>raff Lysekil was approximately36.4 million barrels, 71.0 million barrels and 73.0 million barrels for the six months ended June 30, 2011 and the years endedDecember 31, 2010 and 2009, respectively.<strong>Preem</strong>raff Lysekil’s facilities have been upgraded several times through large capital investments. As a result ofthese improvements, we believe that <strong>Preem</strong>raff Lysekil is one of the most sophisticated and flexible refineries in Europe.The following table summarizes the upgrades to <strong>Preem</strong>raff Lysekil:Upgrade at <strong>Preem</strong>raff Lysekil Function YearVisbreaker.......................................................................... Reduces the viscosity of the fuel oil and increases the 1982yield of heating oil and gasolineFluid Catalytic Cracker...................................................... Converts vacuum gasoil, a semi-finished product, and the 1984bottom fraction from the hydrocracker into gasoline,heating oil and fuel oilMild Hydrocracker............................................................. Desulphurizes and converts vacuum gasoil into lighter 1988products and feedstock for the HydrocrackerIsomerization Unit ............................................................. Converts light naphtha into high-octane, low-benzene 1991gasoline componentsDesulphurization/Dearomatization Unit ............................ Converts conventional heating oil or diesel into virtually 1994sulphur- free, low-aromatic dieselTailgas Treatment Sulphur Recovery Unit ........................ Removes hydrogen sulphide and nitrogen oxides from 1994refinery gases and recovers liquid sulphurPrefractionater.................................................................... Reduces benzene formation in the platformer unit 1999Propylene Recovery Unit................................................... Removes propylene from polygasoline production and 2002refinery fuel gas and recovers propylenePetrol Gas Recovery Unit .................................................. Recovers petrol gas in connection with the loading of 2003products onto tankersHydrocracker Unit ............................................................. Converts vacuum gas oil to lighter, higher-value products 2006Imported crude oil arrives at <strong>Preem</strong>raff Lysekil by way of a single jetty that can accommodate tankers of up to500,000 dead weight tons. Approximately 110 vessels carrying crude oil arrive at <strong>Preem</strong>raff Lysekil each year. Crude oilcan be unloaded at a rate of approximately 113,000 barrels per hour through pipe lines into five underground crude oilstorage caverns. These caverns have been blasted out of solid rock and have an aggregate capacity of approximately38