HTNVY.DUTY CIRCULAR SNWS T ITSTNII ... - Wood Tools

HTNVY.DUTY CIRCULAR SNWS T ITSTNII ... - Wood Tools

HTNVY.DUTY CIRCULAR SNWS T ITSTNII ... - Wood Tools

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

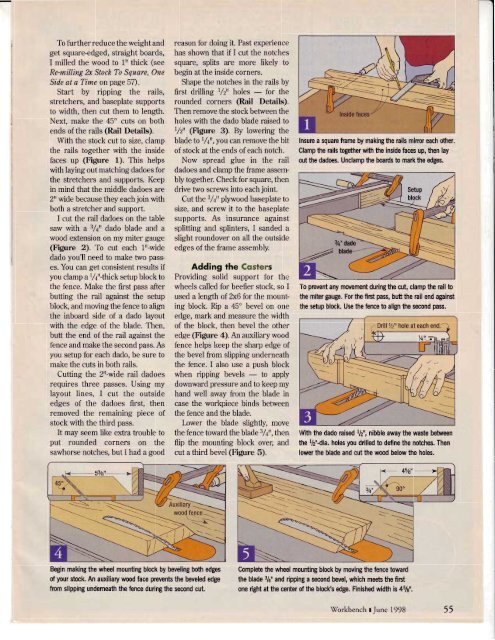

To further reduce the weight andget square-edged, straight boards,I milled the wood to 1rr thick (seeRe-milling 2x Stock To Square, OneSide at a Time on page 57).Start by ripping the rails,stretchers, and baseplate supportsto width, then cut them to length.Next, make the 45" cuts on bothends of the rails (Rail Details).With the stock cut to size, clampthe rails together with the insidefaces up (Figure 1). This helpswith laying out matching dadoes forthe stretchers and supports. Keepin mind that the middle dadoes are2rrwide because they each join withboth a stretcher and support.I cut the rail dadoes on the tablesaw with a s/rtt dado blade and awood etension on my miter gauge(Figure 2). To cut each ilLwidedado you'll need to make two passes. You can get consistent results ifyou clamp ut'lnrt-thick setup block tothe fence. Make the first pass afterbutting the rail against the setupblock, and moving the fence to alignthe inboard side of a dado layoutwith the edge of the blade. Then,butt the end of the rail against thefence and make the second pass. Asyou setup for each dado, be sure tomake the cuts in both rails.Cutting the 2rlwide rail dadoesrequires three passes. Using mylayout lines, I cut the outsideedges of the dadoes first, thenremoved the remaining piece ofstock with the third pass.It may seem like extra trouble toput rounded corners on thesawhorse notches, but I had a goodreason for doing it. Past experiencehas shown that if I cut the notchessquare, splits are more likely tobegin at the inside corners.Shape the notches in the rails byfirst drilling 1/2" holes - for therounded corners (Rail Details).Then remove the stockbetween theholes with the dado blade raised to1/zrr (Figure 3). By lowering theblade to r/tt',you can remove the bitof stock at the ends of each notch.Now spread glue in the raildadoes and clamp the frame assemblytogether. Check for square, thendrive two screws into each joint.Cut the 34rr pl)ryvood baseplate tosize, and screw it to the baseplatesupports. As insurance againstsplitting and splinters, I sanded aslight roundover on all the outsideedges of the frame assembly.Adding the CqstersProviding solid support for thewheels called for beefier stock, so Iused a length of 2x6 for the mountingblock. Rip a 45' bevel on oneedge, mark and measure the widthof the block, then bevel the otheredge (Figure 4). An atxiliarywoodfence helps keep the sharp edge ofthe bevel from stpping underneaththe fence. I also use a push blockwhen ripping bevels - to applydownward pressure and to keep myhand well away from the blade incase the workpiece binds betweenthe fence and the blade.I-ower the blade slightly, movethe fence toward the blade 34", thenflip the mounting block over, andcut a third bevel (Figure 5).lnsurc a squarc frame by making the rails mirrcr each ofter,Clamp the rails together wift the inside faces up, then layout the dadoes. Unclamp the boards b mafi the edges.To prevent any movement during the cut, clamp the rail tothe miter gauge. For the firt pass, butt the nil end againstthe setup block. Use the funce to align the second pass.With the dado taised 12", nibble away the waste betweenthe %"-dia. holes you drilled to define the notches. Thenlower the blade and cut the wood below the holes.oillilt*-,=--=-\S-=s-=-\Begin making the wheel mounting block by beveling both edgesof your stock. An auxiliary wood fuce prevenb the beveled edgefrom slipping underneath the fence during the second cut.Complete the wheel mounting block by moving the funce towardthe blade 3/+" and ripping a second bevel, which meeb the firstone right at the center of the block's edge. Finished width is 45le",\Torkbench I June 1998 55

![Til]tl](https://img.yumpu.com/45878240/1/190x245/tiltl.jpg?quality=85)