EVA Series Installation Operation and Maintenance Manual

EVA Series Installation Operation and Maintenance Manual

EVA Series Installation Operation and Maintenance Manual

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

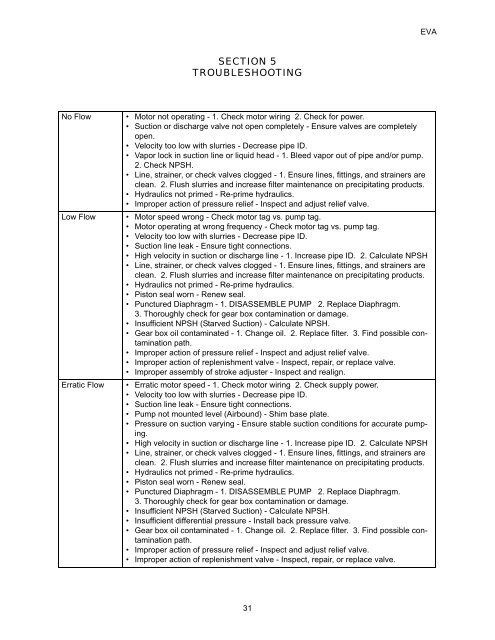

<strong>EVA</strong>SECTION 5TROUBLESHOOTINGNo FlowLow FlowErratic Flow• Motor not operating - 1. Check motor wiring 2. Check for power.• Suction or discharge valve not open completely - Ensure valves are completelyopen.• Velocity too low with slurries - Decrease pipe ID.• Vapor lock in suction line or liquid head - 1. Bleed vapor out of pipe <strong>and</strong>/or pump.2. Check NPSH.• Line, strainer, or check valves clogged - 1. Ensure lines, fittings, <strong>and</strong> strainers areclean. 2. Flush slurries <strong>and</strong> increase filter maintenance on precipitating products.• Hydraulics not primed - Re-prime hydraulics.• Improper action of pressure relief - Inspect <strong>and</strong> adjust relief valve.• Motor speed wrong - Check motor tag vs. pump tag.• Motor operating at wrong frequency - Check motor tag vs. pump tag.• Velocity too low with slurries - Decrease pipe ID.• Suction line leak - Ensure tight connections.• High velocity in suction or discharge line - 1. Increase pipe ID. 2. Calculate NPSH• Line, strainer, or check valves clogged - 1. Ensure lines, fittings, <strong>and</strong> strainers areclean. 2. Flush slurries <strong>and</strong> increase filter maintenance on precipitating products.• Hydraulics not primed - Re-prime hydraulics.• Piston seal worn - Renew seal.• Punctured Diaphragm - 1. DISASSEMBLE PUMP 2. Replace Diaphragm.3. Thoroughly check for gear box contamination or damage.• Insufficient NPSH (Starved Suction) - Calculate NPSH.• Gear box oil contaminated - 1. Change oil. 2. Replace filter. 3. Find possible contaminationpath.• Improper action of pressure relief - Inspect <strong>and</strong> adjust relief valve.• Improper action of replenishment valve - Inspect, repair, or replace valve.• Improper assembly of stroke adjuster - Inspect <strong>and</strong> realign.• Erratic motor speed - 1. Check motor wiring 2. Check supply power.• Velocity too low with slurries - Decrease pipe ID.• Suction line leak - Ensure tight connections.• Pump not mounted level (Airbound) - Shim base plate.• Pressure on suction varying - Ensure stable suction conditions for accurate pumping.• High velocity in suction or discharge line - 1. Increase pipe ID. 2. Calculate NPSH• Line, strainer, or check valves clogged - 1. Ensure lines, fittings, <strong>and</strong> strainers areclean. 2. Flush slurries <strong>and</strong> increase filter maintenance on precipitating products.• Hydraulics not primed - Re-prime hydraulics.• Piston seal worn - Renew seal.• Punctured Diaphragm - 1. DISASSEMBLE PUMP 2. Replace Diaphragm.3. Thoroughly check for gear box contamination or damage.• Insufficient NPSH (Starved Suction) - Calculate NPSH.• Insufficient differential pressure - Install back pressure valve.• Gear box oil contaminated - 1. Change oil. 2. Replace filter. 3. Find possible contaminationpath.• Improper action of pressure relief - Inspect <strong>and</strong> adjust relief valve.• Improper action of replenishment valve - Inspect, repair, or replace valve.31