EVA Series Installation Operation and Maintenance Manual

EVA Series Installation Operation and Maintenance Manual

EVA Series Installation Operation and Maintenance Manual

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

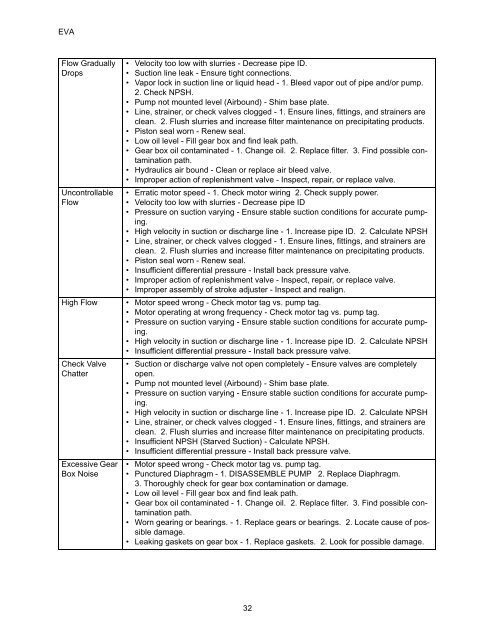

<strong>EVA</strong>Flow GraduallyDropsUncontrollableFlowHigh FlowCheck ValveChatterExcessive GearBox Noise• Velocity too low with slurries - Decrease pipe ID.• Suction line leak - Ensure tight connections.• Vapor lock in suction line or liquid head - 1. Bleed vapor out of pipe <strong>and</strong>/or pump.2. Check NPSH.• Pump not mounted level (Airbound) - Shim base plate.• Line, strainer, or check valves clogged - 1. Ensure lines, fittings, <strong>and</strong> strainers areclean. 2. Flush slurries <strong>and</strong> increase filter maintenance on precipitating products.• Piston seal worn - Renew seal.• Low oil level - Fill gear box <strong>and</strong> find leak path.• Gear box oil contaminated - 1. Change oil. 2. Replace filter. 3. Find possible contaminationpath.• Hydraulics air bound - Clean or replace air bleed valve.• Improper action of replenishment valve - Inspect, repair, or replace valve.• Erratic motor speed - 1. Check motor wiring 2. Check supply power.• Velocity too low with slurries - Decrease pipe ID• Pressure on suction varying - Ensure stable suction conditions for accurate pumping.• High velocity in suction or discharge line - 1. Increase pipe ID. 2. Calculate NPSH• Line, strainer, or check valves clogged - 1. Ensure lines, fittings, <strong>and</strong> strainers areclean. 2. Flush slurries <strong>and</strong> increase filter maintenance on precipitating products.• Piston seal worn - Renew seal.• Insufficient differential pressure - Install back pressure valve.• Improper action of replenishment valve - Inspect, repair, or replace valve.• Improper assembly of stroke adjuster - Inspect <strong>and</strong> realign.• Motor speed wrong - Check motor tag vs. pump tag.• Motor operating at wrong frequency - Check motor tag vs. pump tag.• Pressure on suction varying - Ensure stable suction conditions for accurate pumping.• High velocity in suction or discharge line - 1. Increase pipe ID. 2. Calculate NPSH• Insufficient differential pressure - Install back pressure valve.• Suction or discharge valve not open completely - Ensure valves are completelyopen.• Pump not mounted level (Airbound) - Shim base plate.• Pressure on suction varying - Ensure stable suction conditions for accurate pumping.• High velocity in suction or discharge line - 1. Increase pipe ID. 2. Calculate NPSH• Line, strainer, or check valves clogged - 1. Ensure lines, fittings, <strong>and</strong> strainers areclean. 2. Flush slurries <strong>and</strong> increase filter maintenance on precipitating products.• Insufficient NPSH (Starved Suction) - Calculate NPSH.• Insufficient differential pressure - Install back pressure valve.• Motor speed wrong - Check motor tag vs. pump tag.• Punctured Diaphragm - 1. DISASSEMBLE PUMP 2. Replace Diaphragm.3. Thoroughly check for gear box contamination or damage.• Low oil level - Fill gear box <strong>and</strong> find leak path.• Gear box oil contaminated - 1. Change oil. 2. Replace filter. 3. Find possible contaminationpath.• Worn gearing or bearings. - 1. Replace gears or bearings. 2. Locate cause of possibledamage.• Leaking gaskets on gear box - 1. Replace gaskets. 2. Look for possible damage.32