Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

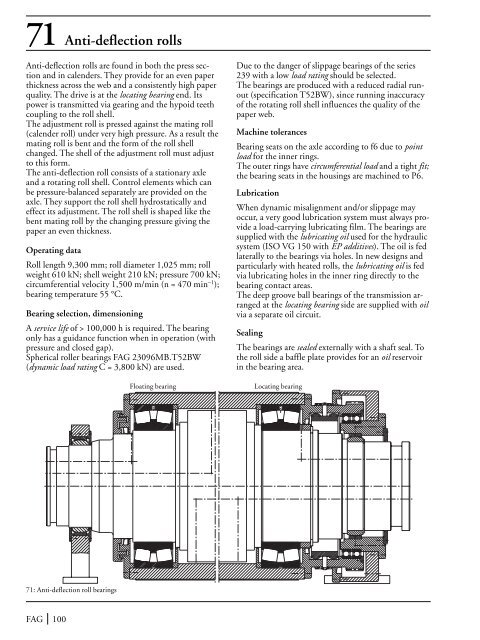

71 Anti-deflection rollsAnti-deflection rolls are found in both the press sectionand in calenders. <strong>The</strong>y provide for an even paperthickness across the web and a consistently high paperquality. <strong>The</strong> drive is at the locating bearing end. Itspower is transmitted via gearing and the hypoid teethcoupling to the roll shell.<strong>The</strong> adjustment roll is pressed against the mating roll(calender roll) under very high pressure. As a result themating roll is bent and the form <strong>of</strong> the roll shellchanged. <strong>The</strong> shell <strong>of</strong> the adjustment roll must adjustto this form.<strong>The</strong> anti-deflection roll consists <strong>of</strong> a stationary axleand a rotating roll shell. Control elements which canbe pressure-balanced separately are provided on theaxle. <strong>The</strong>y support the roll shell hydrostatically andeffect its adjustment. <strong>The</strong> roll shell is shaped like thebent mating roll by the changing pressure giving thepaper an even thickness.Operating dataRoll length 9,300 mm; roll diameter 1,025 mm; rollweight 610 kN; shell weight 210 kN; pressure 700 kN;circumferential velocity 1,500 m/min (n = 470 min –1 );bearing temperature 55 °C.<strong>Bearing</strong> selection, dimensioningA service life <strong>of</strong> > 100,000 h is required. <strong>The</strong> bearingonly has a guidance function when in operation (withpressure and closed gap).Spherical roller bearings FAG 23096MB.T52BW(dynamic load rating C = 3,800 kN) are used.Floating bearingDue to the danger <strong>of</strong> slippage bearings <strong>of</strong> the series239 with a low load rating should be selected.<strong>The</strong> bearings are produced with a reduced radial runout(specification T52BW), since running inaccuracy<strong>of</strong> the rotating roll shell influences the quality <strong>of</strong> thepaper web.Machine tolerances<strong>Bearing</strong> seats on the axle according to f6 due to pointload for the inner rings.<strong>The</strong> outer rings have circumferential load and a tight fit;the bearing seats in the housings are machined to P6.LubricationWhen dynamic misalignment and/or slippage mayoccur, a very good lubrication system must always providea load-carrying lubricating film. <strong>The</strong> bearings aresupplied with the lubricating oil used for the hydraulicsystem (ISO VG 150 with EP additives). <strong>The</strong> oil is fedlaterally to the bearings via holes. In new designs andparticularly with heated rolls, the lubricating oil is fedvia lubricating holes in the inner ring directly to thebearing contact areas.<strong>The</strong> deep groove ball bearings <strong>of</strong> the transmission arrangedat the locating bearing side are supplied with oilvia a separate oil circuit.Sealing<strong>The</strong> bearings are sealed externally with a shaft seal. Tothe roll side a baffle plate provides for an oil reservoirin the bearing area.Locating bearing71: Anti-deflection roll bearingsFAG 100