Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

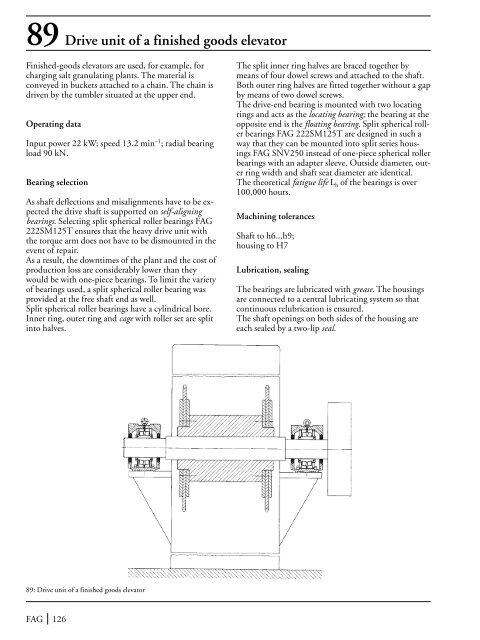

89 Drive unit <strong>of</strong> a finished goods elevatorFinished-goods elevators are used, for example, forcharging salt granulating plants. <strong>The</strong> material isconveyed in buckets attached to a chain. <strong>The</strong> chain isdriven by the tumbler situated at the upper end.Operating dataInput power 22 kW; speed 13.2 min –1 ; radial bearingload 90 kN.<strong>Bearing</strong> selectionAs shaft deflections and misalignments have to be expectedthe drive shaft is supported on self-aligningbearings. Selecting split spherical roller bearings FAG222SM125T ensures that the heavy drive unit withthe torque arm does not have to be dismounted in theevent <strong>of</strong> repair.As a result, the downtimes <strong>of</strong> the plant and the cost <strong>of</strong>production loss are considerably lower than theywould be with one-piece bearings. To limit the variety<strong>of</strong> bearings used, a split spherical roller bearing wasprovided at the free shaft end as well.Split spherical roller bearings have a cylindrical bore.Inner ring, outer ring and cage with roller set are splitinto halves.<strong>The</strong> split inner ring halves are braced together bymeans <strong>of</strong> four dowel screws and attached to the shaft.Both outer ring halves are fitted together without a gapby means <strong>of</strong> two dowel screws.<strong>The</strong> drive-end bearing is mounted with two locatingrings and acts as the locating bearing; the bearing at theopposite end is the floating bearing. Split spherical rollerbearings FAG 222SM125T are designed in such away that they can be mounted into split series housingsFAG SNV250 instead <strong>of</strong> one-piece spherical rollerbearings with an adapter sleeve. Outside diameter, outerring width and shaft seat diameter are identical.<strong>The</strong> theoretical fatigue life L h <strong>of</strong> the bearings is over100,000 hours.Machining tolerancesShaft to h6...h9;housing to H7Lubrication, sealing<strong>The</strong> bearings are lubricated with grease. <strong>The</strong> housingsare connected to a central lubricating system so thatcontinuous relubrication is ensured.<strong>The</strong> shaft openings on both sides <strong>of</strong> the housing areeach sealed by a two-lip seal.89: Drive unit <strong>of</strong> a finished goods elevatorFAG 126