Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

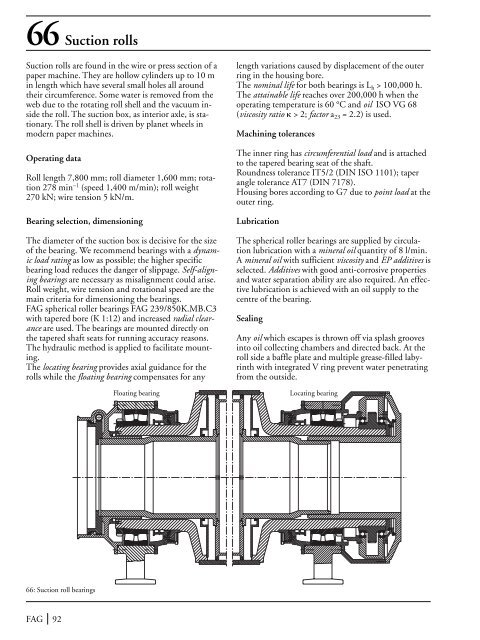

66 Suction rollsSuction rolls are found in the wire or press section <strong>of</strong> apaper machine. <strong>The</strong>y are hollow cylinders up to 10 min length which have several small holes all aroundtheir circumference. Some water is removed from theweb due to the rotating roll shell and the vacuum insidethe roll. <strong>The</strong> suction box, as interior axle, is stationary.<strong>The</strong> roll shell is driven by planet wheels inmodern paper machines.Operating dataRoll length 7,800 mm; roll diameter 1,600 mm; rotation278 min –1 (speed 1,400 m/min); roll weight270 kN; wire tension 5 kN/m.<strong>Bearing</strong> selection, dimensioning<strong>The</strong> diameter <strong>of</strong> the suction box is decisive for the size<strong>of</strong> the bearing. We recommend bearings with a dynamicload rating as low as possible; the higher specificbearing load reduces the danger <strong>of</strong> slippage. Self-aligningbearings are necessary as misalignment could arise.Roll weight, wire tension and rotational speed are themain criteria for dimensioning the bearings.FAG spherical roller bearings FAG 239/850K.MB.C3with tapered bore (K 1:12) and increased radial clearanceare used. <strong>The</strong> bearings are mounted directly onthe tapered shaft seats for running accuracy reasons.<strong>The</strong> hydraulic method is applied to facilitate mounting.<strong>The</strong> locating bearing provides axial guidance for therolls while the floating bearing compensates for anyFloating bearinglength variations caused by displacement <strong>of</strong> the outerring in the housing bore.<strong>The</strong> nominal life for both bearings is L h > 100,000 h.<strong>The</strong> attainable life reaches over 200,000 h when theoperating temperature is 60 °C and oil ISO VG 68(viscosity ratio > 2; factor a 23 = 2.2) is used.Machining tolerances<strong>The</strong> inner ring has circumferential load and is attachedto the tapered bearing seat <strong>of</strong> the shaft.Roundness tolerance IT5/2 (DIN ISO 1101); taperangle tolerance AT7 (DIN 7178).Housing bores according to G7 due to point load at theouter ring.Lubrication<strong>The</strong> spherical roller bearings are supplied by circulationlubrication with a mineral oil quantity <strong>of</strong> 8 l/min.A mineral oil with sufficient viscosity and EP additives isselected. Additives with good anti-corrosive propertiesand water separation ability are also required. An effectivelubrication is achieved with an oil supply to thecentre <strong>of</strong> the bearing.SealingAny oil which escapes is thrown <strong>of</strong>f via splash groovesinto oil collecting chambers and directed back. At theroll side a baffle plate and multiple grease-filled labyrinthwith integrated V ring prevent water penetratingfrom the outside.Locating bearing66: Suction roll bearingsFAG 92