You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

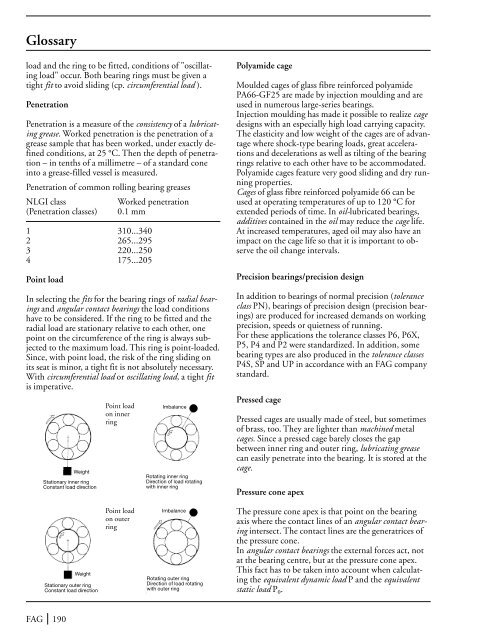

Glossaryload and the ring to be fitted, conditions <strong>of</strong> "oscillatingload" occur. Both bearing rings must be given atight fit to avoid sliding (cp. circumferential load ).PenetrationPenetration is a measure <strong>of</strong> the consistency <strong>of</strong> a lubricatinggrease. Worked penetration is the penetration <strong>of</strong> agrease sample that has been worked, under exactly definedconditions, at 25 °C. <strong>The</strong>n the depth <strong>of</strong> penetration– in tenths <strong>of</strong> a millimetre – <strong>of</strong> a standard coneinto a grease-filled vessel is measured.Penetration <strong>of</strong> common rolling bearing greasesNLGI classWorked penetration(Penetration classes) 0.1 mm1 310...3402 265...2953 220...2504 175...205Point loadIn selecting the fits for the bearing rings <strong>of</strong> radial bearingsand angular contact bearings the load conditionshave to be considered. If the ring to be fitted and theradial load are stationary relative to each other, onepoint on the circumference <strong>of</strong> the ring is always subjectedto the maximum load. This ring is point-loaded.Since, with point load, the risk <strong>of</strong> the ring sliding onits seat is minor, a tight fit is not absolutely necessary.With circumferential load or oscillating load, a tight fitis imperative.WeightStationary inner ringConstant load directionPoint loadon innerringImbalanceRotating inner ringDirection <strong>of</strong> load rotatingwith inner ringPolyamide cageMoulded cages <strong>of</strong> glass fibre reinforced polyamidePA66-GF25 are made by injection moulding and areused in numerous large-series bearings.Injection moulding has made it possible to realize cagedesigns with an especially high load carrying capacity.<strong>The</strong> elasticity and low weight <strong>of</strong> the cages are <strong>of</strong> advantagewhere shock-type bearing loads, great accelerationsand decelerations as well as tilting <strong>of</strong> the bearingrings relative to each other have to be accommodated.Polyamide cages feature very good sliding and dry runningproperties.Cages <strong>of</strong> glass fibre reinforced polyamide 66 can beused at operating temperatures <strong>of</strong> up to 120 °C forextended periods <strong>of</strong> time. In oil-lubricated bearings,additives contained in the oil may reduce the cage life.At increased temperatures, aged oil may also have animpact on the cage life so that it is important to observethe oil change intervals.Precision bearings/precision designIn addition to bearings <strong>of</strong> normal precision (toleranceclass PN), bearings <strong>of</strong> precision design (precision bearings)are produced for increased demands on workingprecision, speeds or quietness <strong>of</strong> running.For these applications the tolerance classes P6, P6X,P5, P4 and P2 were standardized. In addition, somebearing types are also produced in the tolerance classesP4S, SP and UP in accordance with an FAG companystandard.Pressed cagePressed cages are usually made <strong>of</strong> steel, but sometimes<strong>of</strong> brass, too. <strong>The</strong>y are lighter than machined metalcages. Since a pressed cage barely closes the gapbetween inner ring and outer ring, lubricating greasecan easily penetrate into the bearing. It is stored at thecage.Pressure cone apexWeightStationary outer ringConstant load directionPoint loadon outerringImbalanceRotating outer ringDirection <strong>of</strong> load rotatingwith outer ring<strong>The</strong> pressure cone apex is that point on the bearingaxis where the contact lines <strong>of</strong> an angular contact bearingintersect. <strong>The</strong> contact lines are the generatrices <strong>of</strong>the pressure cone.In angular contact bearings the external forces act, notat the bearing centre, but at the pressure cone apex.This fact has to be taken into account when calculatingthe equivalent dynamic load P and the equivalentstatic load P 0 .FAG 190