Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

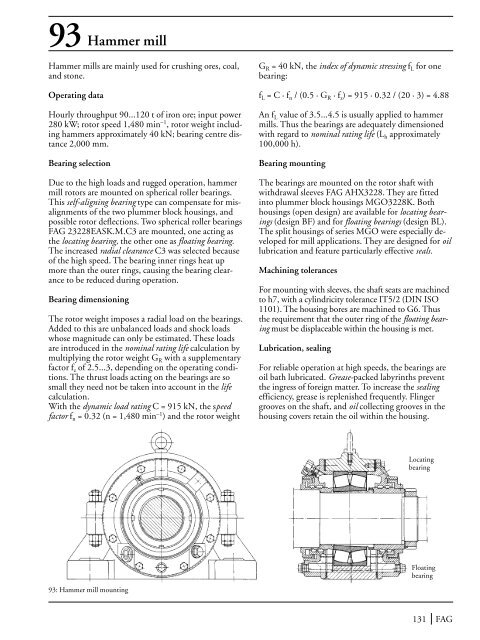

93 Hammer millHammer mills are mainly used for crushing ores, coal,and stone.Operating dataHourly throughput 90...120 t <strong>of</strong> iron ore; input power280 kW; rotor speed 1,480 min –1 , rotor weight includinghammers approximately 40 kN; bearing centre distance2,000 mm.<strong>Bearing</strong> selectionDue to the high loads and rugged operation, hammermill rotors are mounted on spherical roller bearings.This self-aligning bearing type can compensate for misalignments<strong>of</strong> the two plummer block housings, andpossible rotor deflections. Two spherical roller bearingsFAG 23228EASK.M.C3 are mounted, one acting asthe locating bearing, the other one as floating bearing.<strong>The</strong> increased radial clearance C3 was selected because<strong>of</strong> the high speed. <strong>The</strong> bearing inner rings heat upmore than the outer rings, causing the bearing clearanceto be reduced during operation.<strong>Bearing</strong> dimensioning<strong>The</strong> rotor weight imposes a radial load on the bearings.Added to this are unbalanced loads and shock loadswhose magnitude can only be estimated. <strong>The</strong>se loadsare introduced in the nominal rating life calculation bymultiplying the rotor weight G R with a supplementaryfactor f z <strong>of</strong> 2.5...3, depending on the operating conditions.<strong>The</strong> thrust loads acting on the bearings are sosmall they need not be taken into account in the lifecalculation.With the dynamic load rating C = 915 kN, the speedfactor f n = 0.32 (n = 1,480 min –1 ) and the rotor weightG R = 40 kN, the index <strong>of</strong> dynamic stressing f L for onebearing:f L = C · f n / (0.5 · G R · f z ) = 915 · 0.32 / (20 · 3) = 4.88An f L value <strong>of</strong> 3.5...4.5 is usually applied to hammermills. Thus the bearings are adequately dimensionedwith regard to nominal rating life (L h approximately100,000 h).<strong>Bearing</strong> mounting<strong>The</strong> bearings are mounted on the rotor shaft withwithdrawal sleeves FAG AHX3228. <strong>The</strong>y are fittedinto plummer block housings MGO3228K. Bothhousings (open design) are available for locating bearings(design BF) and for floating bearings (design BL).<strong>The</strong> split housings <strong>of</strong> series MGO were especially developedfor mill applications. <strong>The</strong>y are designed for oillubrication and feature particularly effective seals.Machining tolerancesFor mounting with sleeves, the shaft seats are machinedto h7, with a cylindricity tolerance IT5/2 (DIN ISO1101). <strong>The</strong> housing bores are machined to G6. Thusthe requirement that the outer ring <strong>of</strong> the floating bearingmust be displaceable within the housing is met.Lubrication, sealingFor reliable operation at high speeds, the bearings areoil bath lubricated. Grease-packed labyrinths preventthe ingress <strong>of</strong> foreign matter. To increase the sealingefficiency, grease is replenished frequently. Flingergrooves on the shaft, and oil collecting grooves in thehousing covers retain the oil within the housing.LocatingbearingFloatingbearing93: Hammer mill mounting131 FAG