Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

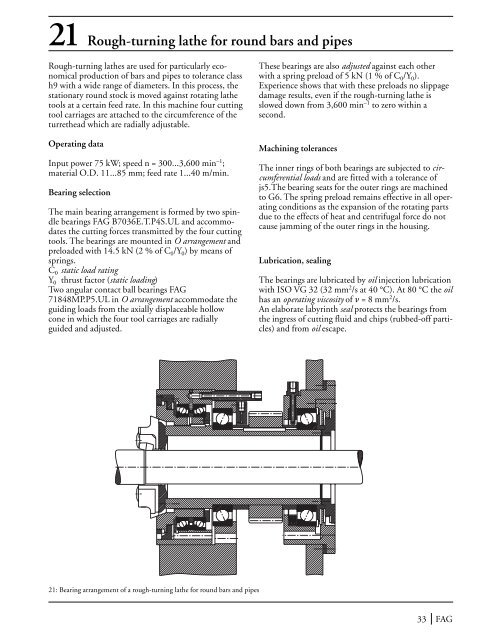

21 Rough-turning lathe for round bars and pipesRough-turning lathes are used for particularly economicalproduction <strong>of</strong> bars and pipes to tolerance classh9 with a wide range <strong>of</strong> diameters. In this process, thestationary round stock is moved against rotating lathetools at a certain feed rate. In this machine four cuttingtool carriages are attached to the circumference <strong>of</strong> theturrethead which are radially adjustable.Operating dataInput power 75 kW; speed n = 300...3,600 min –1 ;material O.D. 11...85 mm; feed rate 1...40 m/min.<strong>Bearing</strong> selection<strong>The</strong> main bearing arrangement is formed by two spindlebearings FAG B7036E.T.P4S.UL and accommodatesthe cutting forces transmitted by the four cuttingtools. <strong>The</strong> bearings are mounted in O arrangement andpreloaded with 14.5 kN (2 % <strong>of</strong> C 0 /Y 0 ) by means <strong>of</strong>springs.C 0 static load ratingY 0 thrust factor (static loading)Two angular contact ball bearings FAG71848MP.P5.UL in O arrangement accommodate theguiding loads from the axially displaceable hollowcone in which the four tool carriages are radiallyguided and adjusted.<strong>The</strong>se bearings are also adjusted against each otherwith a spring preload <strong>of</strong> 5 kN (1 % <strong>of</strong> C 0 /Y 0 ).Experience shows that with these preloads no slippagedamage results, even if the rough-turning lathe isslowed down from 3,600 min –1 to zero within asecond.Machining tolerances<strong>The</strong> inner rings <strong>of</strong> both bearings are subjected to circumferentialloads and are fitted with a tolerance <strong>of</strong>js5.<strong>The</strong> bearing seats for the outer rings are machinedto G6. <strong>The</strong> spring preload remains effective in all operatingconditions as the expansion <strong>of</strong> the rotating partsdue to the effects <strong>of</strong> heat and centrifugal force do notcause jamming <strong>of</strong> the outer rings in the housing.Lubrication, sealing<strong>The</strong> bearings are lubricated by oil injection lubricationwith ISO VG 32 (32 mm 2 /s at 40 °C). At 80 °C the oilhas an operating viscosity <strong>of</strong> = 8 mm 2 /s.An elaborate labyrinth seal protects the bearings fromthe ingress <strong>of</strong> cutting fluid and chips (rubbed-<strong>of</strong>f particles)and from oil escape.21: <strong>Bearing</strong> arrangement <strong>of</strong> a rough-turning lathe for round bars and pipes33 FAG