You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

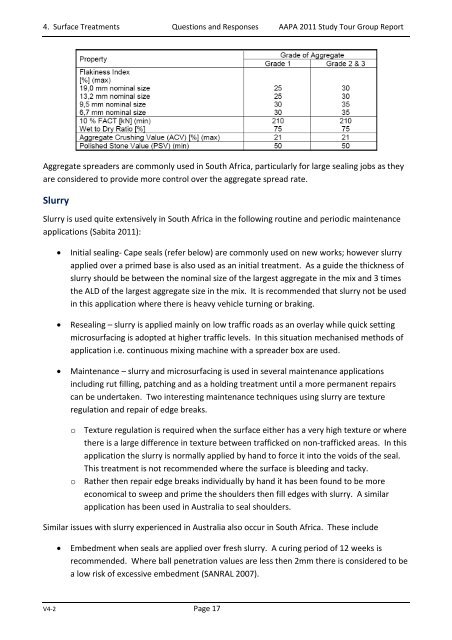

4. Surface Treatments Questions and Responses <strong>AAPA</strong> <strong>2011</strong> <strong>Study</strong> <strong>Tour</strong> Group ReportAggregate spreaders are commonly used in South Africa, particularly for large sealing jobs as theyare considered to provide more control over the aggregate spread rate.SlurrySlurry is used quite extensively in South Africa in the following routine and periodic maintenanceapplications (Sabita <strong>2011</strong>):• Initial sealing- Cape seals (refer below) are commonly used on new works; however slurryapplied over a primed base is also used as an initial treatment. As a guide the thickness ofslurry should be between the nominal size of the largest aggregate in the mix and 3 timesthe ALD of the largest aggregate size in the mix. It is recommended that slurry not be usedin this application where there is heavy vehicle turning or braking.• Resealing – slurry is applied mainly on low traffic roads as an overlay while quick settingmicrosurfacing is adopted at higher traffic levels. In this situation mechanised methods ofapplication i.e. continuous mixing machine with a spreader box are used.• Maintenance – slurry and microsurfacing is used in several maintenance applicationsincluding rut filling, patching and as a holding treatment until a more permanent repairscan be undertaken. Two interesting maintenance techniques using slurry are textureregulation and repair of edge breaks.o Texture regulation is required when the surface either has a very high texture or wherethere is a large difference in texture between trafficked on non-trafficked areas. In thisapplication the slurry is normally applied by hand to force it into the voids of the seal.This treatment is not recommended where the surface is bleeding and tacky.o Rather then repair edge breaks individually by hand it has been found to be moreeconomical to sweep and prime the shoulders then fill edges with slurry. A similarapplication has been used in Australia to seal shoulders.Similar issues with slurry experienced in Australia also occur in South Africa. These include• Embedment when seals are applied over fresh slurry. A curing period of 12 weeks isrecommended. Where ball penetration values are less then 2mm there is considered to bea low risk of excessive embedment (SANRAL 2007).V4-2 Page 17