Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

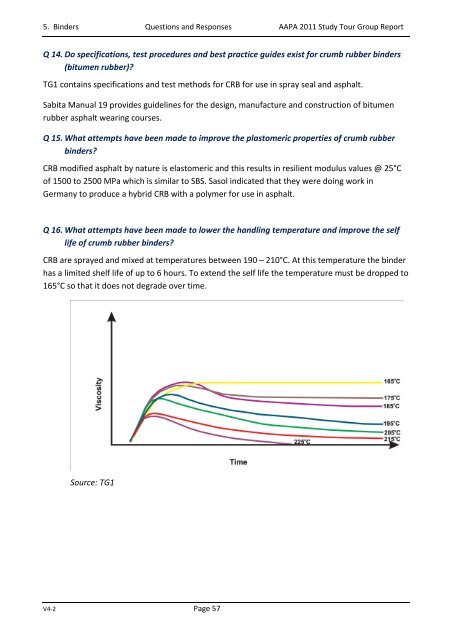

5. Binders Questions and Responses <strong>AAPA</strong> <strong>2011</strong> <strong>Study</strong> <strong>Tour</strong> Group ReportQ 14. Do specifications, test procedures and best practice guides exist for crumb rubber binders(bitumen rubber)?TG1 contains specifications and test methods for CRB for use in spray seal and asphalt.Sabita Manual 19 provides guidelines for the design, manufacture and construction of bitumenrubber asphalt wearing courses.Q 15. What attempts have been made to improve the plastomeric properties of crumb rubberbinders?CRB modified asphalt by nature is elastomeric and this results in resilient modulus values @ 25°Cof 1500 to 2500 MPa which is similar to SBS. Sasol indicated that they were doing work inGermany to produce a hybrid CRB with a polymer for use in asphalt.Q 16. What attempts have been made to lower the handling temperature and improve the selflife of crumb rubber binders?CRB are sprayed and mixed at temperatures between 190 – 210°C. At this temperature the binderhas a limited shelf life of up to 6 hours. To extend the self life the temperature must be dropped to165°C so that it does not degrade over time.Source: TG1V4-2 Page 57