You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

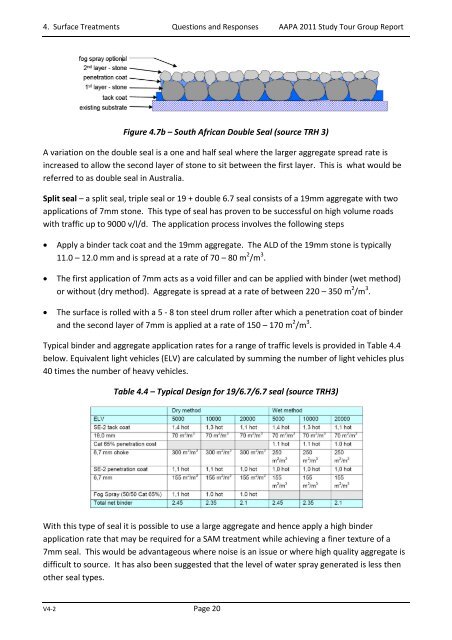

4. Surface Treatments Questions and Responses <strong>AAPA</strong> <strong>2011</strong> <strong>Study</strong> <strong>Tour</strong> Group ReportFigure 4.7b – South African Double Seal (source TRH 3)A variation on the double seal is a one and half seal where the larger aggregate spread rate isincreased to allow the second layer of stone to sit between the first layer. This is what would bereferred to as double seal in Australia.Split seal – a split seal, triple seal or 19 + double 6.7 seal consists of a 19mm aggregate with twoapplications of 7mm stone. This type of seal has proven to be successful on high volume roadswith traffic up to 9000 v/l/d. The application process involves the following steps• Apply a binder tack coat and the 19mm aggregate. The ALD of the 19mm stone is typically11.0 – 12.0 mm and is spread at a rate of 70 – 80 m 2 /m 3 .• The first application of 7mm acts as a void filler and can be applied with binder (wet method)or without (dry method). Aggregate is spread at a rate of between 220 – 350 m 2 /m 3 .• The surface is rolled with a 5 - 8 ton steel drum roller after which a penetration coat of binderand the second layer of 7mm is applied at a rate of 150 – 170 m 2 /m 3 .Typical binder and aggregate application rates for a range of traffic levels is provided in Table 4.4below. Equivalent light vehicles (ELV) are calculated by summing the number of light vehicles plus40 times the number of heavy vehicles.Table 4.4 – Typical Design for 19/6.7/6.7 seal (source TRH3)With this type of seal it is possible to use a large aggregate and hence apply a high binderapplication rate that may be required for a SAM treatment while achieving a finer texture of a7mm seal. This would be advantageous where noise is an issue or where high quality aggregate isdifficult to source. It has also been suggested that the level of water spray generated is less thenother seal types.V4-2 Page 20