You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

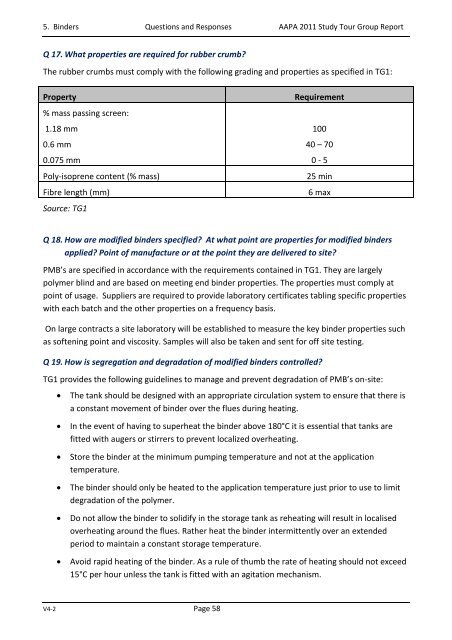

5. Binders Questions and Responses <strong>AAPA</strong> <strong>2011</strong> <strong>Study</strong> <strong>Tour</strong> Group ReportQ 17. What properties are required for rubber crumb?The rubber crumbs must comply with the following grading and properties as specified in TG1:Property% mass passing screen:1.18 mm0.6 mm0.075 mmPoly-isoprene content (% mass)Fibre length (mm)Source: TG1Requirement10040 – 700 - 525 min6 maxQ 18. How are modified binders specified? At what point are properties for modified bindersapplied? Point of manufacture or at the point they are delivered to site?PMB’s are specified in accordance with the requirements contained in TG1. They are largelypolymer blind and are based on meeting end binder properties. The properties must comply atpoint of usage. Suppliers are required to provide laboratory certificates tabling specific propertieswith each batch and the other properties on a frequency basis.On large contracts a site laboratory will be established to measure the key binder properties suchas softening point and viscosity. Samples will also be taken and sent for off site testing.Q 19. How is segregation and degradation of modified binders controlled?TG1 provides the following guidelines to manage and prevent degradation of PMB’s on-site:• The tank should be designed with an appropriate circulation system to ensure that there isa constant movement of binder over the flues during heating.• In the event of having to superheat the binder above 180°C it is essential that tanks arefitted with augers or stirrers to prevent localized overheating.• Store the binder at the minimum pumping temperature and not at the applicationtemperature.• The binder should only be heated to the application temperature just prior to use to limitdegradation of the polymer.• Do not allow the binder to solidify in the storage tank as reheating will result in localisedoverheating around the flues. Rather heat the binder intermittently over an extendedperiod to maintain a constant storage temperature.• Avoid rapid heating of the binder. As a rule of thumb the rate of heating should not exceed15°C per hour unless the tank is fitted with an agitation mechanism.V4-2 Page 58