You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

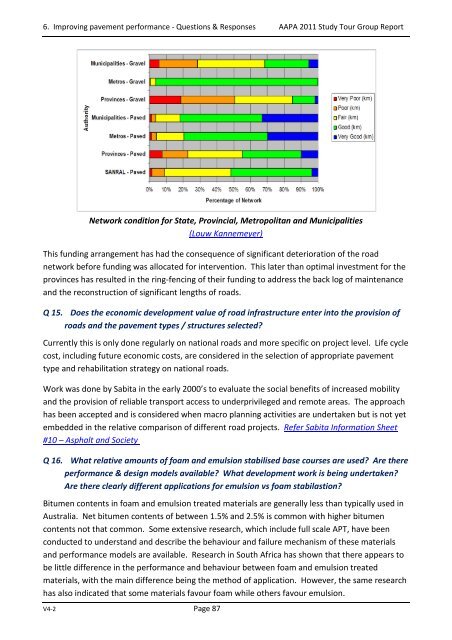

6. Improving pavement performance - Questions & Responses <strong>AAPA</strong> <strong>2011</strong> <strong>Study</strong> <strong>Tour</strong> Group ReportNetwork condition for State, Provincial, Metropolitan and Municipalities(Louw Kannemeyer)This funding arrangement has had the consequence of significant deterioration of the roadnetwork before funding was allocated for intervention. This later than optimal investment for theprovinces has resulted in the ring-fencing of their funding to address the back log of maintenanceand the reconstruction of significant lengths of roads.Q 15. Does the economic development value of road infrastructure enter into the provision ofroads and the pavement types / structures selected?Currently this is only done regularly on national roads and more specific on project level. Life cyclecost, including future economic costs, are considered in the selection of appropriate pavementtype and rehabilitation strategy on national roads.Work was done by Sabita in the early 2000’s to evaluate the social benefits of increased mobilityand the provision of reliable transport access to underprivileged and remote areas. The approachhas been accepted and is considered when macro planning activities are undertaken but is not yetembedded in the relative comparison of different road projects. Refer Sabita Information Sheet#10 – Asphalt and SocietyQ 16. What relative amounts of foam and emulsion stabilised base courses are used? Are thereperformance & design models available? What development work is being undertaken?Are there clearly different applications for emulsion vs foam stabilastion?Bitumen contents in foam and emulsion treated materials are generally less than typically used inAustralia. Net bitumen contents of between 1.5% and 2.5% is common with higher bitumencontents not that common. Some extensive research, which include full scale APT, have beenconducted to understand and describe the behaviour and failure mechanism of these materialsand performance models are available. Research in South Africa has shown that there appears tobe little difference in the performance and behaviour between foam and emulsion treatedmaterials, with the main difference being the method of application. However, the same researchhas also indicated that some materials favour foam while others favour emulsion.V4-2 Page 87