You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

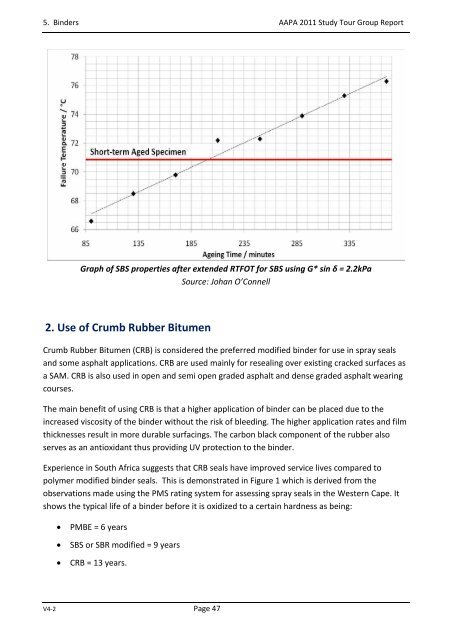

5. Binders <strong>AAPA</strong> <strong>2011</strong> <strong>Study</strong> <strong>Tour</strong> Group ReportGraph of SBS properties after extended RTFOT for SBS using G* sin δ = 2.2kPaSource: Johan O’Connell2. Use of Crumb Rubber BitumenCrumb Rubber Bitumen (CRB) is considered the preferred modified binder for use in spray sealsand some asphalt applications. CRB are used mainly for resealing over existing cracked surfaces asa SAM. CRB is also used in open and semi open graded asphalt and dense graded asphalt wearingcourses.The main benefit of using CRB is that a higher application of binder can be placed due to theincreased viscosity of the binder without the risk of bleeding. The higher application rates and filmthicknesses result in more durable surfacings. The carbon black component of the rubber alsoserves as an antioxidant thus providing UV protection to the binder.Experience in South Africa suggests that CRB seals have improved service lives compared topolymer modified binder seals. This is demonstrated in Figure 1 which is derived from theobservations made using the PMS rating system for assessing spray seals in the Western Cape. Itshows the typical life of a binder before it is oxidized to a certain hardness as being:• PMBE = 6 years• SBS or SBR modified = 9 years• CRB = 13 years.V4-2 Page 47