roof framing connections in conventional residential construction

roof framing connections in conventional residential construction

roof framing connections in conventional residential construction

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

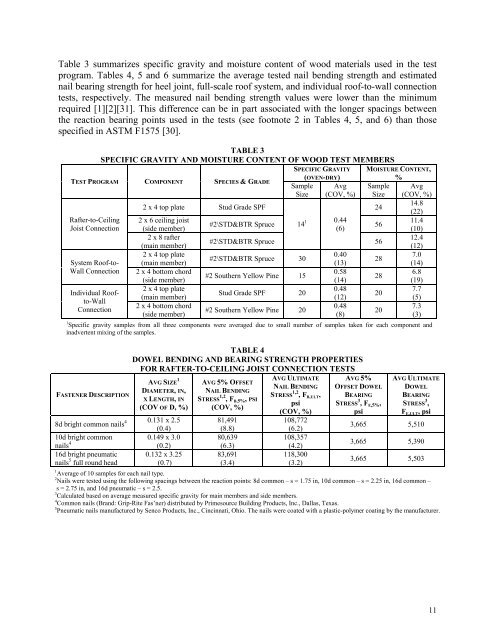

Table 3 summarizes specific gravity and moisture content of wood materials used <strong>in</strong> the testprogram. Tables 4, 5 and 6 summarize the average tested nail bend<strong>in</strong>g strength and estimatednail bear<strong>in</strong>g strength for heel jo<strong>in</strong>t, full-scale <strong>roof</strong> system, and <strong>in</strong>dividual <strong>roof</strong>-to-wall connectiontests, respectively. The measured nail bend<strong>in</strong>g strength values were lower than the m<strong>in</strong>imumrequired [1][2][31]. This difference can be <strong>in</strong> part associated with the longer spac<strong>in</strong>gs betweenthe reaction bear<strong>in</strong>g po<strong>in</strong>ts used <strong>in</strong> the tests (see footnote 2 <strong>in</strong> Tables 4, 5, and 6) than thosespecified <strong>in</strong> ASTM F1575 [30].TABLE 3SPECIFIC GRAVITY AND MOISTURE CONTENT OF WOOD TEST MEMBERSSPECIFIC GRAVITY MOISTURE CONTENT,(OVEN-DRY)%TEST PROGRAM COMPONENT SPECIES & GRADESample Avg Sample AvgSize (COV, %) Size (COV, %)14.82 x 4 top plate Stud Grade SPF 24(22)Rafter-to-Ceil<strong>in</strong>g 2 x 6 ceil<strong>in</strong>g joist11.4#2\STD&BTR Spruce 14 1 0.4456Joist Connection (side member)(6)(10)2 x 8 rafter12.4#2\STD&BTR Spruce56(ma<strong>in</strong> member)(12)2 x 4 top plate0.407.0#2\STD&BTR Spruce 3028System Roof-to- (ma<strong>in</strong> member)(13)(14)Wall Connection 2 x 4 bottom chord0.586.8#2 Southern Yellow P<strong>in</strong>e 1528(side member)(14)(19)2 x 4 top plate0.487.7Individual Roofto-WallStud Grade SPF 2020(ma<strong>in</strong> member)(12)(5)Connection#2 Southern Yellow P<strong>in</strong>e 20202 x 4 bottom chord(side member)1 Specific gravity samples from all three components were averaged due to small number of samples taken for each component and<strong>in</strong>advertent mix<strong>in</strong>g of the samples.FASTENER DESCRIPTION0.48(8)TABLE 4DOWEL BENDING AND BEARING STRENGTH PROPERTIESFOR RAFTER-TO-CEILING JOIST CONNECTION TESTSAVG SIZE 1DIAMETER, IN,X LENGTH, IN(COV OF D, %)8d bright common nails 4 0.131 x 2.5(0.4)10d bright common 0.149 x 3.0nails 4 (0.2)16d bright pneumatic 0.132 x 3.25nails 5 full round head(0.7)AVG 5% OFFSETNAIL BENDINGSTRESS 1,2 , F B,5% , PSI(COV, %)81,491(8.8)80,639(6.3)83,691(3.4)AVG ULTIMATENAIL BENDINGSTRESS 1,2 , F B,ULT ,psi(COV, %)108,772(6.2)108,357(4.2)118,300(3.2)AVG 5%OFFSET DOWELBEARINGSTRESS 3 , F E,5% ,psi7.3(3)AVG ULTIMATEDOWELBEARINGSTRESS 3 ,F E,ULT , psi3,665 5,5103,665 5,3903,665 5,5031 Average of 10 samples for each nail type.2 Nails were tested us<strong>in</strong>g the follow<strong>in</strong>g spac<strong>in</strong>gs between the reaction po<strong>in</strong>ts: 8d common – s = 1.75 <strong>in</strong>, 10d common – s = 2.25 <strong>in</strong>, 16d common –s = 2.75 <strong>in</strong>, and 16d pneumatic – s = 2.5.3 Calculated based on average measured specific gravity for ma<strong>in</strong> members and side members.4 Common nails (Brand: Grip-Rite Fas’ner) distributed by Primesource Build<strong>in</strong>g Products, Inc., Dallas, Texas.5 Pneumatic nails manufactured by Senco Products, Inc., C<strong>in</strong>c<strong>in</strong>nati, Ohio. The nails were coated with a plastic-polymer coat<strong>in</strong>g by the manufacturer.11