roof framing connections in conventional residential construction

roof framing connections in conventional residential construction

roof framing connections in conventional residential construction

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

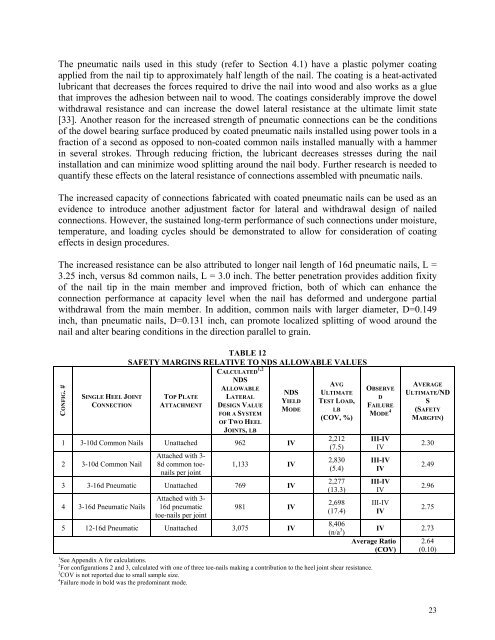

The pneumatic nails used <strong>in</strong> this study (refer to Section 4.1) have a plastic polymer coat<strong>in</strong>gapplied from the nail tip to approximately half length of the nail. The coat<strong>in</strong>g is a heat-activatedlubricant that decreases the forces required to drive the nail <strong>in</strong>to wood and also works as a gluethat improves the adhesion between nail to wood. The coat<strong>in</strong>gs considerably improve the dowelwithdrawal resistance and can <strong>in</strong>crease the dowel lateral resistance at the ultimate limit state[33]. Another reason for the <strong>in</strong>creased strength of pneumatic <strong>connections</strong> can be the conditionsof the dowel bear<strong>in</strong>g surface produced by coated pneumatic nails <strong>in</strong>stalled us<strong>in</strong>g power tools <strong>in</strong> afraction of a second as opposed to non-coated common nails <strong>in</strong>stalled manually with a hammer<strong>in</strong> several strokes. Through reduc<strong>in</strong>g friction, the lubricant decreases stresses dur<strong>in</strong>g the nail<strong>in</strong>stallation and can m<strong>in</strong>imize wood splitt<strong>in</strong>g around the nail body. Further research is needed toquantify these effects on the lateral resistance of <strong>connections</strong> assembled with pneumatic nails.The <strong>in</strong>creased capacity of <strong>connections</strong> fabricated with coated pneumatic nails can be used as anevidence to <strong>in</strong>troduce another adjustment factor for lateral and withdrawal design of nailed<strong>connections</strong>. However, the susta<strong>in</strong>ed long-term performance of such <strong>connections</strong> under moisture,temperature, and load<strong>in</strong>g cycles should be demonstrated to allow for consideration of coat<strong>in</strong>geffects <strong>in</strong> design procedures.The <strong>in</strong>creased resistance can be also attributed to longer nail length of 16d pneumatic nails, L =3.25 <strong>in</strong>ch, versus 8d common nails, L = 3.0 <strong>in</strong>ch. The better penetration provides addition fixityof the nail tip <strong>in</strong> the ma<strong>in</strong> member and improved friction, both of which can enhance theconnection performance at capacity level when the nail has deformed and undergone partialwithdrawal from the ma<strong>in</strong> member. In addition, common nails with larger diameter, D=0.149<strong>in</strong>ch, than pneumatic nails, D=0.131 <strong>in</strong>ch, can promote localized splitt<strong>in</strong>g of wood around thenail and alter bear<strong>in</strong>g conditions <strong>in</strong> the direction parallel to gra<strong>in</strong>.CONFIG. #SINGLE HEEL JOINTCONNECTIONTABLE 12SAFETY MARGINS RELATIVE TO NDS ALLOWABLE VALUESTOP PLATEATTACHMENTCALCULATED 1,2NDSALLOWABLELATERALDESIGN VALUEFOR A SYSTEMOF TWO HEELJOINTS, LBNDSYIELDMODE1 3-10d Common Nails Unattached 962 IV2 3-10d Common NailAttached with 3-8d common toenailsper jo<strong>in</strong>t1,133 IV3 3-16d Pneumatic Unattached 769 IV4 3-16d Pneumatic NailsAttached with 3-16d pneumatictoe-nails per jo<strong>in</strong>t981 IV5 12-16d Pneumatic Unattached 3,075 IVAVGULTIMATETEST LOAD,LB(COV, %)2,212(7.5)2,830(5.4)2,277(13.3)2,698(17.4)8,406(n/a 3 )1 See Appendix A for calculations.2 For configurations 2 and 3, calculated with one of three toe-nails mak<strong>in</strong>g a contribution to the heel jo<strong>in</strong>t shear resistance.3 COV is not reported due to small sample size.4 Failure mode <strong>in</strong> bold was the predom<strong>in</strong>ant mode.OBSERVEDFAILUREMODE 4III-IVIVIII-IVIVIII-IVIVIII-IVIVAverage Ratio(COV)AVERAGEULTIMATE/NDS(SAFETYMARGFIN)2.302.492.962.75IV 2.732.64(0.10)23