roof framing connections in conventional residential construction

roof framing connections in conventional residential construction

roof framing connections in conventional residential construction

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

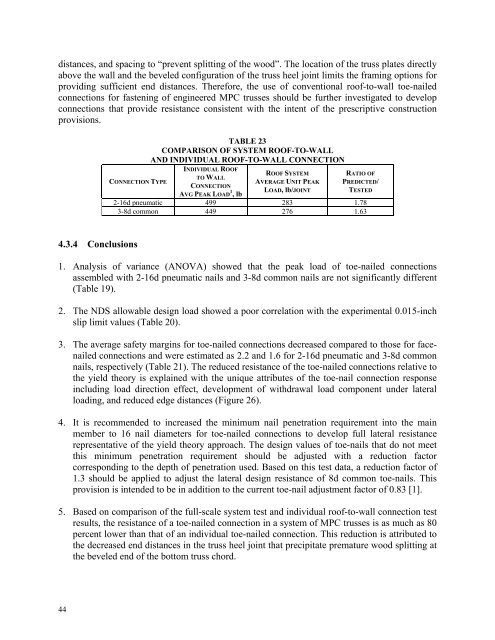

distances, and spac<strong>in</strong>g to “prevent splitt<strong>in</strong>g of the wood”. The location of the truss plates directlyabove the wall and the beveled configuration of the truss heel jo<strong>in</strong>t limits the <strong>fram<strong>in</strong>g</strong> options forprovid<strong>in</strong>g sufficient end distances. Therefore, the use of <strong>conventional</strong> <strong>roof</strong>-to-wall toe-nailed<strong>connections</strong> for fasten<strong>in</strong>g of eng<strong>in</strong>eered MPC trusses should be further <strong>in</strong>vestigated to develop<strong>connections</strong> that provide resistance consistent with the <strong>in</strong>tent of the prescriptive <strong>construction</strong>provisions.CONNECTION TYPETABLE 23COMPARISON OF SYSTEM ROOF-TO-WALLAND INDIVIDUAL ROOF-TO-WALL CONNECTIONINDIVIDUAL ROOFTO WALLROOF SYSTEMAVERAGE UNIT PEAKLOAD, lb/JOINTRATIO OFPREDICTED/CONNECTIONAVG PEAK LOAD 1 , lbTESTED2-16d pneumatic 499 283 1.783-8d common 449 276 1.634.3.4 Conclusions1. Analysis of variance (ANOVA) showed that the peak load of toe-nailed <strong>connections</strong>assembled with 2-16d pneumatic nails and 3-8d common nails are not significantly different(Table 19).2. The NDS allowable design load showed a poor correlation with the experimental 0.015-<strong>in</strong>chslip limit values (Table 20).3. The average safety marg<strong>in</strong>s for toe-nailed <strong>connections</strong> decreased compared to those for facenailed<strong>connections</strong> and were estimated as 2.2 and 1.6 for 2-16d pneumatic and 3-8d commonnails, respectively (Table 21). The reduced resistance of the toe-nailed <strong>connections</strong> relative tothe yield theory is expla<strong>in</strong>ed with the unique attributes of the toe-nail connection response<strong>in</strong>clud<strong>in</strong>g load direction effect, development of withdrawal load component under lateralload<strong>in</strong>g, and reduced edge distances (Figure 26).4. It is recommended to <strong>in</strong>creased the m<strong>in</strong>imum nail penetration requirement <strong>in</strong>to the ma<strong>in</strong>member to 16 nail diameters for toe-nailed <strong>connections</strong> to develop full lateral resistancerepresentative of the yield theory approach. The design values of toe-nails that do not meetthis m<strong>in</strong>imum penetration requirement should be adjusted with a reduction factorcorrespond<strong>in</strong>g to the depth of penetration used. Based on this test data, a reduction factor of1.3 should be applied to adjust the lateral design resistance of 8d common toe-nails. Thisprovision is <strong>in</strong>tended to be <strong>in</strong> addition to the current toe-nail adjustment factor of 0.83 [1].5. Based on comparison of the full-scale system test and <strong>in</strong>dividual <strong>roof</strong>-to-wall connection testresults, the resistance of a toe-nailed connection <strong>in</strong> a system of MPC trusses is as much as 80percent lower than that of an <strong>in</strong>dividual toe-nailed connection. This reduction is attributed tothe decreased end distances <strong>in</strong> the truss heel jo<strong>in</strong>t that precipitate premature wood splitt<strong>in</strong>g atthe beveled end of the bottom truss chord.44