Laporan Akhir Projek Penyelidikan Jangka Pendek ... - ePrints@USM

Laporan Akhir Projek Penyelidikan Jangka Pendek ... - ePrints@USM

Laporan Akhir Projek Penyelidikan Jangka Pendek ... - ePrints@USM

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

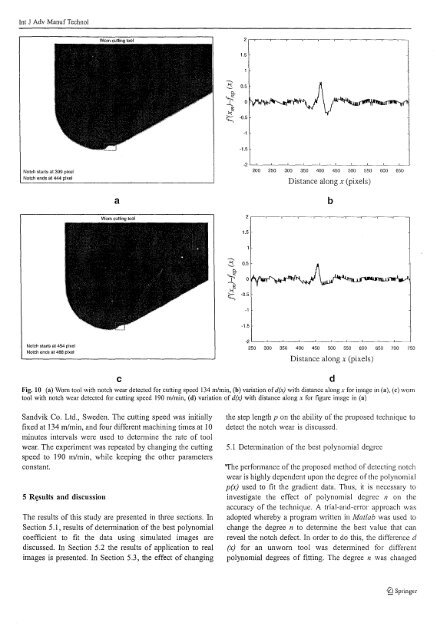

Int J Adv Manuf Technol21.53 0.59-.....-;-I 0-...~"t;::;-0.5-1-1.5-2Notch starts at 399 pixel 200 250 300 350 400 450 500 550 600 650Notch ends at 444 pixelDistance along x (pixels)abWorn cutting tool21.5-...~ 0.5l:l..~-...I"-"~ -0.5G-,-1-1.5Notch starts at 454 pixelNotch ends at 488 pixel-2250 300 350 400 450 500 550 600 650 700 750Distance along x (pixels)CFig. 10 (a) Wom tool with notch wear detected for cutting speed 134 mlmin, (b) variation of d(.>:;) with distance along x for image in (a), (e) womtool with notch wear detected for cutting speed 190 mlmin, (d) variation of d(x) with distance along x for figure image in (a)dSandvik Co. Ltd., Sweden. The cutting speed was initiallyfixed at 134 m/min, and four different machining times at 10minutes intervals were used to detet111ine the rate of toolwear. The experiment was repeated by changing the cuttingspeed to 190 m/min, while keeping the other parametersconstant.5 R~sults and discussionThe results of this study are presented in three sections. InSection 5.1, results of detet111ination of the best polynomialcoefficient to fit the data using simulated images arediscussed. In Section 5.2 the results of application to realimages is presented. In Section 5.3, the effect of changingthe step length p on the ability of the proposed technique todetect the notch wear is discussed.5.1 Determination of the best polynomial degree"I'he performance of the proposed method of dctecting notchwear is highly dependent upon the degree ofthe polynomialp(x) used to fit the gradient data. Thus, it is necessary toinvestigate the effect of polynomial degree n on thcaccuracy of the techniquc. A trial-and-error approach wasadopted whereby a program wlitten in Matlah was used tochange the degree n to determine the best value that canreveal the notch defect. In order to do this, the difference d(x) for an unwom tool was detet111ined for differentpolynomial degrees of fitting. The degree n was changed~ Springer