Statistical models of elasticity in main chain and smectic liquid ...

Statistical models of elasticity in main chain and smectic liquid ...

Statistical models of elasticity in main chain and smectic liquid ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

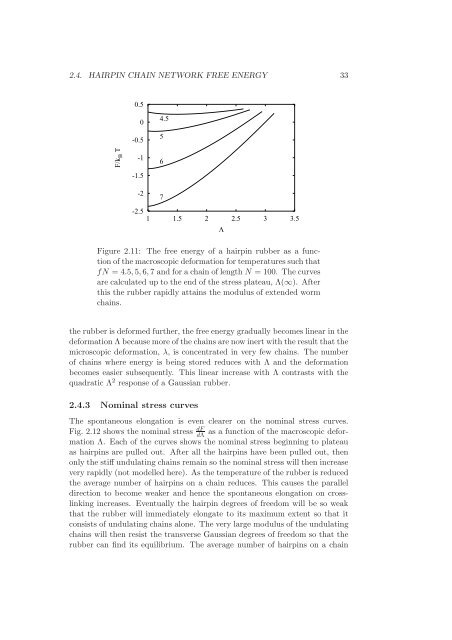

2.4. HAIRPIN CHAIN NETWORK FREE ENERGY 330.5F/k B T0-0.5-1-1.5-24.5567-2.51 1.5 2 2.5 3 3.5Figure 2.11: The free energy <strong>of</strong> a hairp<strong>in</strong> rubber as a function<strong>of</strong>themacroscopicdeformationfortemperaturessuchthatfN = 4.5,5,6,7 <strong>and</strong>foracha<strong>in</strong> <strong>of</strong>length N = 100. Thecurvesare calculated up to the end <strong>of</strong> the stress plateau, Λ(∞). Afterthis the rubber rapidly atta<strong>in</strong>s the modulus <strong>of</strong> extended wormcha<strong>in</strong>s.Λthe rubberis deformed further, the freeenergy gradually becomes l<strong>in</strong>ear <strong>in</strong> thedeformationΛbecausemore<strong>of</strong>thecha<strong>in</strong>sarenow<strong>in</strong>ertwiththeresultthatthemicroscopic deformation, λ, is concentrated <strong>in</strong> very few cha<strong>in</strong>s. The number<strong>of</strong> cha<strong>in</strong>s where energy is be<strong>in</strong>g stored reduces with Λ <strong>and</strong> the deformationbecomes easier subsequently. This l<strong>in</strong>ear <strong>in</strong>crease with Λ contrasts with thequadratic Λ 2 response <strong>of</strong> a Gaussian rubber.2.4.3 Nom<strong>in</strong>al stress curvesThe spontaneous elongation is even clearer on the nom<strong>in</strong>al stress curves.Fig. 2.12 shows the nom<strong>in</strong>al stress dFdΛas a function <strong>of</strong> the macroscopic deformationΛ. Each <strong>of</strong> the curves shows the nom<strong>in</strong>al stress beg<strong>in</strong>n<strong>in</strong>g to plateauas hairp<strong>in</strong>s are pulled out. After all the hairp<strong>in</strong>s have been pulled out, thenonly the stiff undulat<strong>in</strong>g cha<strong>in</strong>s rema<strong>in</strong> so the nom<strong>in</strong>al stress will then <strong>in</strong>creasevery rapidly (not modelled here). As the temperature <strong>of</strong> the rubberis reducedthe average number <strong>of</strong> hairp<strong>in</strong>s on a cha<strong>in</strong> reduces. This causes the paralleldirection to become weaker <strong>and</strong> hence the spontaneous elongation on crossl<strong>in</strong>k<strong>in</strong>g<strong>in</strong>creases. Eventually the hairp<strong>in</strong> degrees <strong>of</strong> freedom will be so weakthat the rubber will immediately elongate to its maximum extent so that itconsists <strong>of</strong> undulat<strong>in</strong>g cha<strong>in</strong>s alone. The very large modulus <strong>of</strong> the undulat<strong>in</strong>gcha<strong>in</strong>s will then resist the transverse Gaussian degrees <strong>of</strong> freedom so that therubber can f<strong>in</strong>d its equilibrium. The average number <strong>of</strong> hairp<strong>in</strong>s on a cha<strong>in</strong>