Automotive Refinishing Policy Manual - Sacramento Metropolitan Air ...

Automotive Refinishing Policy Manual - Sacramento Metropolitan Air ...

Automotive Refinishing Policy Manual - Sacramento Metropolitan Air ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

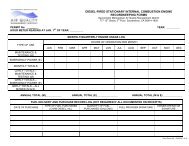

777 12 TH STREET, 3 RD FLOOR (916) 874-4800SACRAMENTO, CA 95814-1908 FAX (916) 874-4899SACRAMENTO METROPOLITANAIR QUALITY MANAGEMENT DISTRICTNATIONAL EMISSION STANDARD FOR HAZARDOUS AIR POLLUTANTS – PAINT STRIPPING ANDMISCELLANEOUS SURFACE COATING OPERATIONS (40 CFR 63 SUBPART HHHHHH)Applicability: This regulation applies to paint stripping operations that involve the use of chemical strippersthat contain methylene chloride (MeCl), Chemical Abstract Service number 75092, in paint removal processesand/or autobody refinishing operations that encompass motor vehicle and mobile equipment spray-appliedsurface coating operations.If spray applied coatings do not contain chromium (Cr), lead (Pb), manganese (Mn), nickel (Ni), orcadmium (Cd), and you have filed a petition for exemption, and have received written confirmationfrom the U.S. Environmental Protection Agency (U.S. EPA) approving your petition, and also do notperform paint stripping activities using methylene chloride (MeCl), then your source is not subject tothis NESHAP (40 CFR 63 Subpart HHHHHH) or any of the following conditions (Condition Nos. 19-28).NOTIFICATIONS:19.. Initial Notification: Existing sources shall notify the U.S. EPA, no later than January 11, 2010, that thefacility is subject to the standards and if not yet in compliance, when the source will be in compliance bysubmitting an initial notification form.[Basis: 40 CFR 63 Subpart HHHHHH, Section 63.11175(a)]20.. Notice of Compliance: Existing sources shall be in compliance with the applicable requirements no laterthan March 11, 2011. The facility shall submit to the U.S. EPA a certification of compliance on or beforethat date.[Basis: 40 CFR 63 Subpart HHHHHH, Section 63.11175(b)]GENERAL:21. All spray painting must be performed inside a spray booth or prep station with a roof and at least threewalls or curtains (when refinishing vehicle subassemblies), or a roof and four complete walls or completeside curtains (when refinishing complete vehicles or mobile equipment) and must be ventilated so that airis drawn into the booth. The exhaust must be equipped with a filter system that is designed to capture atleast 98% of paint overspray.[Basis: 40 CFR 63 Subpart HHHHHH, Sections 63.11173(e)2(i)-63.11173(e)2(iii)]22. Spray guns used in the coating operation must be one of the following types:A. High-Volume Low-Pressure (HVLP)B. ElectrostaticC. Any other equivalent spray method demonstrated to achieve a transfer efficiency equal to one of theother allowed types of spray guns, which has been approved in writing by the <strong>Air</strong> Pollution ControlOfficer, and submitted to and approved by the U.S. EPA.[Basis: 40 CFR 63 Subpart HHHHHH, Section 63.11173(e)3]23. Paint spray gun cleaning must be done so that an atomized mist or spray of the cleaning solvent is notcreated outside a container that collects used gun cleaning solvent.[Basis: 40 CFR 63 Subpart HHHHHH, Section 63.11173(e)4]PAGE 7 OF 9 PAGESREVOCABLE AND NON-TRANSFERABLEPERMIT NOS.: XXXXX