Report 36 d,e,f,s,i.qxd:Report - KBA

Report 36 d,e,f,s,i.qxd:Report - KBA

Report 36 d,e,f,s,i.qxd:Report - KBA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

plate loading and mounting. The<br />

system can be automated in stages.<br />

Plates conveyed as if<br />

by an unseen hand<br />

Automatic plate feed and disposal at<br />

the press are controlled by a computer-assisted<br />

plate logistics management<br />

system (PLM). In the first<br />

step the exposed plates are seized<br />

from the delivery of the punching<br />

and bending machine by <strong>KBA</strong> Plate-<br />

Sorter, an intelligent robot gripper.<br />

They are then identified via a barcode,<br />

subjected to a quality check<br />

(optional) and sorted according to<br />

the designated printing couple into<br />

the <strong>KBA</strong> PlateBox transport magazine,<br />

which has already been locked<br />

onto the transport vehicle.<br />

The intelligent transport vehicle,<br />

<strong>KBA</strong> PlateTrain, can hold up to<br />

five magazines, one of which is reserved<br />

for the first used plates to be<br />

removed from the tower. Each of<br />

the other magazines holds four new<br />

single plates or two new doublespread<br />

plates plus slots for used<br />

plates. Two and three carriages respectively<br />

are required for one side<br />

of a 4/2 and a 6/2 tower. <strong>KBA</strong> Plate-<br />

Train, which is suspended from an<br />

overhead rail that is freely configurable<br />

to suit plant architecture,<br />

conveys the plates to a position<br />

above the relevant tower.<br />

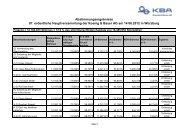

Tracking level<br />

Planning level<br />

<strong>KBA</strong> PlateLoader removes the PlateBox magazines from the PlateTrain<br />

transport vehicle and passes them, correctly positioned, to the<br />

PlateTronic automatic plate changers in the press<br />

Plate logistics management (PLM)<br />

Printshop management and tracking system<br />

Production scheduling system Console<br />

Plate workflow control<br />

Pre-press<br />

Execution level<br />

Sequence<br />

Plate logistics management system<br />

<strong>KBA</strong> PlateTrain<br />

<strong>KBA</strong> PlateBox<br />

scheduling<br />

Exposure Plate bending Plate inspection Magazine loading<br />

Plate change<br />

<strong>KBA</strong><br />

PlateSorter<br />

Plate exchange<br />

Co-ordination level<br />

<strong>KBA</strong><br />

PlateTrain<br />

Interim storage<br />

Magazine transport Plate removal Ready<br />

<strong>KBA</strong><br />

PlateLoader<br />

<strong>KBA</strong> PlateTronic<br />

plate change<br />

Magazine transport<br />

The computer-controlled PLM system co-ordinates, monitors and controls all individual sequences<br />

as well as the entire <strong>KBA</strong> PlateTrans plate-logistics process<br />

Specifications<br />

<strong>KBA</strong> PlateBox transport magazine<br />

• Max. weight: 3 kg<br />

• Capacity: 4 single or two-double-spread<br />

plates plus used plates<br />

• Identification via 2-D matrix code<br />

<strong>KBA</strong> PlateTrain transport vehicle<br />

• Max. load: 50 kg<br />

• Average speed: 0.7 to 1 m/s<br />

Unrivalled plate-changing speed<br />

In the next step the PlateBox magazines<br />

with the new plates are transferred<br />

by the <strong>KBA</strong> PlateLoader robot<br />

to the <strong>KBA</strong> PlateTronic automatic<br />

plate-changing units in the press.<br />

Prior to this the robot will have removed<br />

any magazines with used<br />

plates and transferred them to the<br />

train.<br />

The plate-changing sequence itself<br />

takes just two minutes or so<br />

and is thus twice as fast as any other<br />

robotic systems available on the<br />

market.<br />

High-performance<br />

Multicar system<br />

<strong>KBA</strong> PlateRail is an unmanned system<br />

for conveying plate magazines<br />

to the Cortina and Commander CT<br />

printing towers. Unlike similar systems<br />

from other manufacturers<br />

<strong>KBA</strong> PlateRail incorporates Swisslog-<br />

Telelift’s MultiCar system, which allows<br />

the individual towers and<br />

optional buffer sections to be<br />

reached via a system of switchpoints.<br />

On its return journey the train<br />

stops at an offloading station where<br />

the used plates are removed automatically<br />

and the PlateBox magazines<br />

reallocated. The magazines<br />

are subsequently reinserted in the<br />

train at the loading station ready to<br />

accept new plates.<br />

The flow chart above shows<br />

how the relevant sequences are coordinated<br />

and controlled, how the<br />

processes in subordinated systems<br />

interact, and how the entire process<br />

is safeguarded and monitored by<br />

the computer-assisted plate logistics<br />

management system PLM.<br />

Klaus Schmidt<br />

klaus.schmidt@kba.com<br />

<strong>Report</strong> <strong>36</strong> | 2010 37