Report 36 d,e,f,s,i.qxd:Report - KBA

Report 36 d,e,f,s,i.qxd:Report - KBA

Report 36 d,e,f,s,i.qxd:Report - KBA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Sheetfed Offset | Niche markets<br />

tion methods. FSC certification has<br />

already been completed, the compressors<br />

have been connected to<br />

the heating circuit and now provide<br />

hot water in summer via heat exchangers.<br />

Terminic managing director Wolfgang Rolla<br />

du Rosey checking one of the trimmed<br />

calendars for which the new Rapida 106<br />

(in the background) mainly prints the<br />

backing boards<br />

Grupo Nación: <strong>KBA</strong> showcase in Central America<br />

Rapidas power along in Comet’s wake<br />

For Grupo Nación in San José, 20 November<br />

2008 was a day to remember.<br />

Eagerly watched by an audience of<br />

customers and suppliers, president<br />

Manuel Jiménez had the pleasure of inaugurating<br />

three new Rapida 105 fivecolour<br />

presses simultaneously. It was<br />

also the day on which Costa Rica’s leading<br />

print provider officially completed<br />

the transition to <strong>KBA</strong> for all its sheetfed<br />

technology, following a similar move in<br />

web with the start-up of a Comet press<br />

in 2004.<br />

6 <strong>Report</strong> <strong>36</strong> | 2010<br />

Fully automated<br />

calendar production<br />

Twice as many staff are engaged in<br />

finishing as in the press hall, and<br />

they include electromechanical engineers<br />

and bicycle mechanics. This<br />

is because all the machinery used in<br />

calendar processing was specifically<br />

engineered for terminic’s product<br />

range and manufactured as a oneoff<br />

item. All the production sequences<br />

following cutting, collating<br />

and glue-binding are handled automatically<br />

by a single machine: these<br />

include groove-routing the backing<br />

boards, applying the calendar<br />

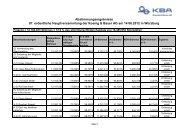

Typical calendar production sequence<br />

• Print date sections • Print backing boards<br />

• Cut into piles of 12 • Laminate onto corrugated (optional)<br />

• Collate • Film laminate (optional)<br />

• Glue-bind<br />

• Groove and trim<br />

• Glue<br />

• Die-cut date window and attach<br />

• Fold<br />

• Pack<br />

Grey, black and red – the dominant colours<br />

in the calendar blocks were adopted for the<br />

interior design of the offices<br />

blocks, die-stamping and applying<br />

the date windows, folding the finished<br />

calendars and packing them<br />

in corrugated sleeves. All at a speed<br />

of 1,800 cycles per hour. Maintaining<br />

and setting such complex<br />

machinery demands an intimate<br />

knowledge of the mechanical workings<br />

involved.<br />

Around 98 per cent of terminic’s<br />

workload is handled inhouse,<br />

with the application of a<br />

high-gloss film on luxury title images<br />

being the only task outsourced.<br />

The number of calendars<br />

produced has climbed steadily since<br />

the first post-war products came off<br />

the presses in 1950. Prior to shipment<br />

throughout the world the calendars<br />

are gently enveloped in the<br />

enticing aroma of coffee emanating<br />

from the nearby roasting plant –<br />

which, of course, is also a regular<br />

customer, in this instance for terminic’s<br />

4-months-to-view calendars.<br />

Martin Dänhardt<br />

martin.daenhardt@kba.com<br />

From the left: Grupo Nación’s executive vice-president for production Mario Hernández with Jürgen Kibler of <strong>KBA</strong> agency Gevisa Artes Gráficas<br />

and Ronald Rojas, managing director of Grupo Nación’s print operation, at one of the three new five-colour Rapida 105s