Report 36 d,e,f,s,i.qxd:Report - KBA

Report 36 d,e,f,s,i.qxd:Report - KBA

Report 36 d,e,f,s,i.qxd:Report - KBA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

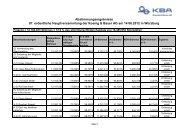

€569.03<br />

parable press is 15% lower than for<br />

the Rapida 142 with peripherals, its<br />

hourly rate is 18% higher. The Rapida’s<br />

reduced rate is largely the result<br />

of its higher output in tandem<br />

with a fully automated, interlinked<br />

logistics system. Lower labour costs<br />

and much lower energy consumption<br />

with <strong>KBA</strong>’s VariDry dryer also<br />

helped trim costs (see article on energy<br />

efficiency, pages 22-23).<br />

When calculating the respective<br />

output levels of the two presses we<br />

took as our basis the makeready<br />

times and average run length per<br />

job. As the top right-hand graph on<br />

page 8 illustrates, a complete job<br />

change on the Rapida 142 takes just<br />

23 minutes – little more than half<br />

the time on the rival press. A major<br />

reason for this is the Rapida’s advanced<br />

level of automation and simultaneous<br />

washing cycles. Higher<br />

automation is also the reason why<br />

changes of coating, printing plates<br />

and coating plates are also much<br />

faster on the Rapida.<br />

2,300 more jobs<br />

per year<br />

Shorter makeready times mean that<br />

the Rapida can print a much larger<br />

number of jobs per shift or day.<br />

Assuming an average run length<br />

of 5,000 sheets per job, the<br />

15,000sph Rapida 142’s higher<br />

level of automation and modestly<br />

higher production speed enable it<br />

to print 2,316 more jobs or<br />

11,583,000 more sheets per year<br />

than the cheaper rival press.<br />

The two graphs at the bottom of<br />

page 8 show the output in jobs and<br />

sheets respectively on the Rapida<br />

Per-job costs<br />

Specifications <strong>KBA</strong> Rapida 142-6+coater Comparable press<br />

Plinth ☑ ☑<br />

Automated nonstop feeder ☑ ☑<br />

Automated nonstop delivery ☑ ☑<br />

Interlinked pile logistics ☑ PileTronic ☐ Not interlinked<br />

Automatic plate change ☑ FAPC ☐ Semi-automatic<br />

Washing system ☑ Blanket/impression cylinders, rollers ☑ Blanket/impression cylinders, rollers<br />

Simultaneous washing ☑ CleanTronic Synchro ☐ Not available<br />

Automatic coating plate change ☑ ☐ Manual<br />

Coating system cleaning ☑ Automatic ☐ Manual<br />

Register system ☑ Automatic Camera Register ☐ Not available<br />

Energy-efficient dryer ☑ VariDry ☐ Not available<br />

Inline colour measurement/control ☑ QualiTronic CC ☑<br />

Online PDF control ☑ DensiTronic PDF ☐ Not available<br />

Machine overheads <strong>KBA</strong> Rapida 142-6+coater Comparable press<br />

Working days per year 250 250<br />

Working hours per shift 7.4 7.4<br />

Number of shifts 3 3<br />

Gross capacity utilisation rate 300 % 300 %<br />

Net capacity utilisation rate<br />

Printing as proportion of<br />

90 % 85 %<br />

production output 90 % 85 %<br />

Makeready per job 23 minutes 45 minutes<br />

Maximum production speed 15,000 sheets/h 14,000 sheets/h<br />

Energy-efficient dryer VariDry Not available<br />

Average run length 5,000 sheets 5,000 sheets<br />

Price of press 100 % 85 %<br />

Payback period 37 months 38 months<br />

Calculated hourly rate 375 euros 443 euros<br />

142 and the comparable press for<br />

average run lengths of between<br />

1,000 and 15,000 sheets. They can<br />

be calculated individually for any<br />

printing plant.<br />

The per-job costs for the two<br />

presses depend to a large extent on<br />

output. In the graph below it can be<br />

seen that, for an assumed average<br />

run length of 5,000 sheets, the per-<br />

Comparable press <strong>KBA</strong> Rapida 142-6+coater Gain with Rapida 142<br />

Per-job costs<br />

€1,100<br />

€1,000<br />

€900<br />

€800<br />

€700<br />

€600<br />

€500<br />

€400<br />

€300<br />

€200<br />

€100<br />

€309.80 €259.23<br />

Rapida 142, cost gain<br />

€0<br />

€0<br />

10,3<strong>36</strong> 8,724 7,531 6,625 5,914 5,340 4,868 4,473 4,137 3,848 3,596 3,376 3,181 3,007 2,852 Jobs / year<br />

1,000 2,000 3,000 4,000 5,000 6,000 7,000 8,000 9,000 10,000 11,000 12,000 13,000 14,000 15,000 Ø run length (sh)<br />

€400<br />

€350<br />

€300<br />

€250<br />

€200<br />

€150<br />

€100<br />

€50<br />

job costs with the Rapida 142 are<br />

€259.30 lower than with the comparable<br />

press.<br />

No false economies<br />

While there is some truth in the<br />

much-repeated argument that a<br />

highly productive press is only<br />

worth the extra money if it is<br />

utilised to the full, it is wrong to<br />

conclude that a cheaper, less productive<br />

press is the right choice<br />

where order volumes leave a lot to<br />

be desired. This defensive investment<br />

philosophy ignores the significant<br />

cost drawback of competing<br />

with rivals whose equipment is<br />

much more productive.<br />

Pre-investment analysis<br />

The examples given, based on an average<br />

run length of 5,000 sheets,<br />

indicate that even if the initial capital<br />

cost is higher, it may still be<br />

wiser to go for a highly automated<br />

press line with correspondingly<br />

shorter makeready times. Where<br />

run lengths are generally long and<br />

there are fewer changes, makeready<br />

times necessarily play a minor role.<br />

But where short runs dominate the<br />

production schedule, and this typically<br />

applies to printers of cosmetics<br />

and pharmaceutical packaging,<br />

they can be a key factor – along<br />

with labour costs, energy consumption<br />

and waste rates – in determining<br />

economic viability. In view of<br />

the flexibility demanded today, a<br />

press that performs well on every<br />

measure may therefore prove to be<br />

the better business option. The<br />

Rapidas fit the bill.<br />

Printers’ job structures differ<br />

enormously. When contemplating<br />

the purchase of new kit, these differences<br />

can be addressed by conducting<br />

individual productivity and<br />

cost-efficiency analyses. <strong>KBA</strong> is always<br />

happy to help.<br />

Jürgen Veil<br />

juergen.veil@kba.com<br />

<strong>Report</strong> <strong>36</strong> | 2010 9