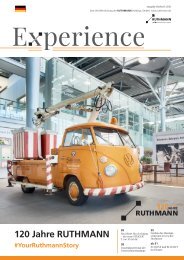

Experience Issue Spring 2016

The customer magazine of RUTHMANN.

The customer magazine of RUTHMANN.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

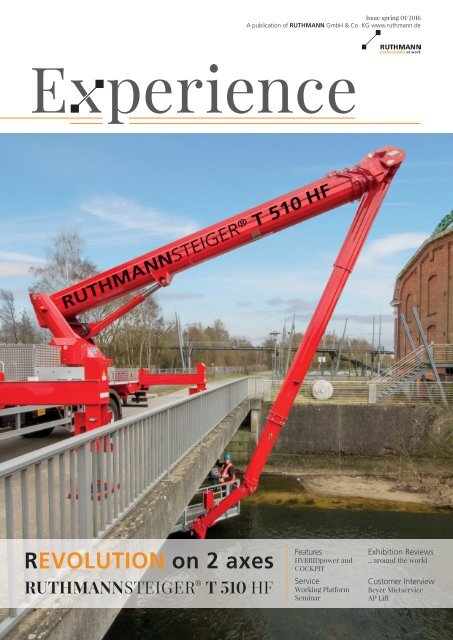

<strong>Issue</strong> spring 01/<strong>2016</strong><br />

A publication of RUTHMANN GmbH & Co. KG www.ruthmann.de<br />

REVOLUTION on 2 axes<br />

RUTHMANNSTEIGER ® T 510 HF<br />

Features<br />

HYBRIDpower and<br />

COCKPIT<br />

Service<br />

Working Platform<br />

Seminar<br />

Exhibition Reviews<br />

... around the world<br />

Customer Interview<br />

Beyer Mietservice<br />

AP Lift

Take advantage of our attractive STEIGER ® ‘s in<br />

stock to update your fleet.<br />

We offer you the possibility to complete your fleet of truck mounted working platforms IN THE<br />

QUICKEST TIME POSSIBLE with innovative, current technology! Our comprehensive range of<br />

direct ‚ready to go‘ storage or demonstration working platforms makes this possible!<br />

Whether you wish to invest in replacement machinery or you would like to build up capacities in<br />

the short term, just contact us. It would be our pleasure to answer your request.<br />

Have we aroused your interest?<br />

... then please contact Michael Heinzl (Head of Sales/ Back Office), by phone:<br />

+49 2863 204-246 or by E-mail: michael.heinzl@ruthmann.de,<br />

www.ruthmann.de/short-available

INHALT<br />

CONTENTS<br />

Topic overview<br />

4...........Message from Management<br />

6...........Cover Story<br />

51 m on 2 axes –<br />

FOR THE FIRST TIME EVER<br />

10...........Global News<br />

Denmark, The Netherlands, Poland, USA,<br />

Belgium, Spain<br />

15...........Features<br />

HYBRIDpower, RUTHMANNCOCKPIT,<br />

Bird‘s-eye view<br />

19...........People<br />

STEIGER ® T 510 HF in operation at bridge<br />

works.<br />

22...........New Products<br />

STEIGER ® T 360<br />

STEIGER ® T 170<br />

SKYBIRD 215I<br />

28...........Service<br />

31...........Exhibition Reviews<br />

... around the world<br />

33...........Customer Story CARGOLOADER ®<br />

35...........Customer Interview<br />

Beyer Mietservice, Germany<br />

AP Lift, Spain<br />

41...........Dealer Story<br />

42............... Imprint<br />

| 3

MESSAGE FROM MANAGEMENT<br />

REVOLUTION<br />

Innovations with true<br />

added value<br />

Pictures in cooperation with Movie Park Germany.<br />

| 4

MESSAGE FROM MANAGEMENT<br />

Uwe Stapper, Uwe Strotmann, Rolf Kulawik<br />

Dear customers, interested<br />

parties, dear readers,<br />

The second issue of our<br />

RUTHMANN magazine was<br />

completed perfectly in time for<br />

the mega industry event “bauma<br />

<strong>2016</strong>”.<br />

We invite you to get exclusive<br />

impressions of innovations that<br />

we will be showing for the first<br />

time at the exhibition.<br />

At the same time, we present a<br />

review relating to the great<br />

events that have happened since<br />

the date of the first publication<br />

of our <strong>Experience</strong> magazine in<br />

the fall of 2015.<br />

This reminds us once more to<br />

say THANK YOU. First and<br />

foremost to our customers as<br />

our continued success in 2015<br />

stems from the trust you place<br />

in us. Once again turnover<br />

increased significantly in all<br />

business fields in 2014.<br />

Further continuous stable<br />

numbers are envisaged for the<br />

current fiscal year <strong>2016</strong> thanks<br />

to the high order backlog and<br />

the orders which were already<br />

received during the first three<br />

months. We foresee increased<br />

growth again this year compared<br />

with the 2015 figures.<br />

We will further optimize the<br />

production run and output and<br />

build additional capacities to<br />

meet the increasing demand and<br />

to continue to offer attractive<br />

delivery times.<br />

With our bauma trade fair motto<br />

“REVOLUTION”, that can also be<br />

seen as the “RUTHMANN<br />

EVOLUTION”, we want to<br />

document that we have created<br />

product innovations which<br />

offer true added value for our<br />

customers. We have attained<br />

this with creative ideas and<br />

progressive development which<br />

is significantly influenced by<br />

our market experience.<br />

We promise you that after the<br />

bauma it will not be the end!<br />

We will continue at full pelt!<br />

Your RUTHMANN<br />

MANAGEMENT<br />

| 5

COVER STORY<br />

51 m on 2 axes –<br />

FOR THE FIRST TIME EVER<br />

At bauma <strong>2016</strong>, we will be adding two brand new “highflex”-STEIGER ® -models to our extremely<br />

successful HEIGHT performance-series.<br />

Providing world record<br />

performance capabilities in a<br />

highly competitive environment,<br />

always works to the customer’s<br />

advantage. Over the past several<br />

years, we at RUTHMANN have<br />

become market leader in the<br />

large-scale equipment segment.<br />

Continuous innovations have<br />

made it all possible. The many<br />

exciting HEIGHT performancemodels,<br />

have given us an<br />

excellent name throughout the<br />

entire industry. The two new<br />

STEIGER ® T 510 HF and T 570<br />

HF models being presented at<br />

bauma <strong>2016</strong>, are an indication<br />

that we intend to further<br />

strengthen and expand our<br />

market-leading position in<br />

Germany and around the world.<br />

Selection galore<br />

With over 200 HEIGHT<br />

performance-units now sold<br />

since the series was first<br />

launched in 2012, these exciting<br />

RUTHMANNSTEIGER ® -models<br />

probably belong to the most<br />

successful large-scale, truckmounted<br />

aerial work platform<br />

series in the world. Even before<br />

these most-recent additions<br />

– which the company refers to<br />

as “highflex” models – our<br />

customers had already had the<br />

largest selection of models to<br />

choose from. We would also like<br />

to emphasize that all models in<br />

the popular series have a<br />

modular design featuring many<br />

identical parts/components.<br />

This design not only maximizes<br />

operating comfort and<br />

| 6

COVER STORY<br />

convenience but also ensures<br />

that individual parts are readily<br />

available at all times. The two<br />

new ‘highflex’ models are a nice<br />

addition to the other seven<br />

HEIGHT performance-<br />

STEIGER ® -models with working<br />

heights that range from 38 m<br />

to 72 m.<br />

World record<br />

through<br />

engineering<br />

proficiency<br />

The STEIGER ® T 510 HF features<br />

a 51 m working height. This is<br />

the first time ever that a truckmounted<br />

aerial work platform<br />

manufacturer has been able to<br />

offer a working height of over 50<br />

m on a 2-axle truck chassis. The<br />

new T 510 HF is even available<br />

on an all-wheel drive chassis. In<br />

the 50 m category – which until<br />

now had only been available on<br />

3-axle trucks – T 510 HF<br />

customers/operators will have<br />

an extremely competitive model<br />

at their disposal. A 2-axle chassis<br />

is much lighter, less expensive,<br />

and more agile. With a maximum<br />

lateral outreach of 33 m, it soon<br />

becomes clear that the T 510 HF<br />

signifies a real engineering<br />

breakthrough. It offers 3 more<br />

metres of working height and<br />

1 additional metre in lateral<br />

outreach compared to the<br />

STEIGER ® T 480 – the previous<br />

leader in this category.<br />

Maximum agility<br />

when working up<br />

high<br />

The “HF” in the name of both<br />

brand new STEIGER ® -models<br />

stands for “highflex”. This term<br />

encapsulates the extraordinary<br />

developments in basket and jib<br />

rotation angle design that<br />

maximize operational versatility<br />

and mobility at the job site. The<br />

maximum highflex basket<br />

rotation angle is an amazing 440°<br />

and the jib (RÜSSEL ® ) has a<br />

rotation angle of 220°.<br />

With the unique basket design<br />

and time-tested “upright work<br />

basket” concept, highflex<br />

operators are able to reach high<br />

up objects with utmost precision<br />

and agility. New possibilities also<br />

arise when working “below<br />

ground” and “up, over and<br />

behind” objects. The highflex<br />

development gives operators<br />

many technical advantages at<br />

the job site and provides added<br />

value for our customers.<br />

| 7

COVER STORY<br />

Length is<br />

paramount<br />

The telescopic system of the<br />

upper boom has been further<br />

extended to provide operators<br />

with even greater versatility.<br />

Since 2012, our customers have<br />

also opted for models in the<br />

HEIGHT performance-series<br />

because of the long upper boom<br />

system with long telescoping<br />

extension. The maximum upper<br />

boom length gives the operator<br />

the reach capabilities needed<br />

when working up high. With the<br />

revised telescoping upper boom<br />

system, highflex operators now<br />

have an additional 2.5 m of<br />

upper boom reach at their<br />

disposal. The maximum total<br />

length of the telescoping upper<br />

boom system with jib (RÜSSEL ® )<br />

is now 18.5 m – another<br />

practical, market-leading<br />

feature.<br />

Ideal for “under<br />

and over” as well<br />

as “over and<br />

under”<br />

The new highflex-models still<br />

feature our tried and tested<br />

“upright work basket.” This<br />

innovative concept provides<br />

tremendous benefits at the job<br />

site. When navigating around<br />

objects high off the ground (e.g.<br />

under existing pipelines), the jib<br />

can be carefully positioned to<br />

allow work to be carried out<br />

behind the pipe. On highflex<br />

models, this advantage is further<br />

enhanced by the new work<br />

basket/jib design. The swivelling<br />

jib provides a 2 x 220° basket<br />

rotation angle. Operators of<br />

these new STEIGER ® -models<br />

can easily navigate over objects<br />

with the jib in lowered/<br />

retracted position and still have<br />

a basket rotation angle of up to<br />

440° at their disposal. With this<br />

innovative new boom system,<br />

assignments on masts/poles,<br />

buildings, and overhangs can be<br />

carried out with greater<br />

precision than ever before.

COVER STORY<br />

The second new<br />

innovation<br />

Our management and engineers<br />

soon realized that a second<br />

STEIGER ® -model could be<br />

developed and constructed<br />

simultaneously using the same<br />

innovative parts/components<br />

utilized in the T 510 HF. The<br />

second new highflex STEIGER ®<br />

T 570 HF has a 57 m working<br />

height and 41 m lateral outreach.<br />

It offers the same benefits as the<br />

T 510 HF, but is designed for<br />

3-axle truck chassis with a 26 t<br />

gross vehicle weight rating<br />

(GVWR).<br />

Highflex chassis<br />

selection<br />

As with almost all other<br />

RUTHMANNSTEIGER ® units,<br />

highflex models are available on<br />

a wide variety of different makes<br />

and models. There are all-wheel<br />

drive chassis for amazing offroad<br />

capabilities, vehicles under<br />

4 m in height with compact<br />

overall length, and GVWcompliant<br />

trucks with sufficient<br />

load capacity. The STEIGER ®<br />

advantages are truly astounding.<br />

Many useful<br />

accessories<br />

On models in the popular<br />

HEIGHT performance-<br />

STEIGER ® -series, customers can<br />

choose from a wide range of<br />

options. The two newest models<br />

in this series are no exception.<br />

The list includes hybrid<br />

powertrains, outrigger LED<br />

flood lights, folding seats and TV<br />

camera brackets, Lift-Up<br />

Systems, material winches,<br />

diverse heating systems, and<br />

hyCLEANER adapters. Almost<br />

anything is possible. Standard<br />

options such as outrigger pads<br />

and box bodies on loading beds<br />

are, of course, also included.<br />

Our motto at the bauma <strong>2016</strong><br />

trade show is “REVOLUTION.”<br />

This can also be interpreted as<br />

“RUTHMANN-EVOLUTION”.<br />

Through creative ideas,<br />

experience, and progressive<br />

development, the responsible<br />

players have provided<br />

customers with tremendous<br />

added value and benefits.<br />

Preview of<br />

upcoming<br />

innovations: T 650<br />

HF and T 750 HF<br />

Good news for prospective<br />

German and global clients<br />

interested in truck-mounted<br />

aerial work platforms with even<br />

greater performance<br />

capabilities. At bauma <strong>2016</strong>, we<br />

will be announcing the addition<br />

of two more highflex STEIGER ®<br />

models, scheduled to make their<br />

debut in October, <strong>2016</strong>, that can<br />

be ordered now. The names of<br />

the upcoming models – T 650<br />

HF and T 750 HF – give us a hint<br />

of what lies ahead.<br />

We also plan to launch two more<br />

STEIGER ® -models in other<br />

categories this year. This means<br />

that the German manufacturer<br />

will introduce a total of six new<br />

STEIGER ® truck-mounted aerial<br />

work platforms in <strong>2016</strong> alone. •

GLOBAL NEWS<br />

Denmark<br />

Another HEIGHT performance-STEIGER ® for Denmark<br />

The rental company Slagelse Liftudlejning ApS (Denmark) quickly realised the HEIGHT performanceseries<br />

was the perfect solution to offer its customers in the large-scale truck mounted segment.<br />

The delivery of the STEIGER ® ‘s<br />

T 540 took place on site at our<br />

factory in Gescher-Hochmoor.<br />

During the delivery and training<br />

on our HEIGHT performance-<br />

STEIGER ® ‘s T 540, Anders<br />

Lindboe (Slagelse Liftudlejning<br />

throughout the entire purchase<br />

process!”<br />

“Several unique features made<br />

the difference for the<br />

RUTHMANN‘s T 540. Especially<br />

the concept of the up to 16 m<br />

long upper boom including the<br />

additionally movable basket<br />

In addition to its compact size<br />

– a total length of only 11.90 m<br />

and a height of 3.90 m –<br />

Slagelse’s latest flagship: the<br />

STEIGER ® T 540 excels with<br />

optimum performance specs of<br />

54 m working height and 40 m<br />

outreach.<br />

We – the team of RUTHMANN<br />

– are proud that we, together<br />

with our competent Danish sales<br />

and service partner TIME<br />

DANMARK, could convince the<br />

well-known Danish rental<br />

company Slagelse Liftudlejning<br />

ApS that the HEIGHT<br />

performance-STEIGER ® was<br />

the right choice.<br />

For more information on<br />

Slagelse Liftudlejning ApS visit:<br />

www.slagelselift.dk •<br />

Pictured here from left to right: Per Trend Poulsen (TIME DANMARK),<br />

Anders Lindboe (Slagelse Liftudlejning), Herman Rasmussen (TIME DANMARK)<br />

and Arnt Valsted (Slagelse Liftudlejning).<br />

ApS) confirmed his reasons for<br />

purchasing this model: “The first<br />

impressions we got from<br />

RUTHMANN and our sales and<br />

service partner >TIME<br />

DANMARK< was decisive for us.<br />

We felt safe with both<br />

companies and perfectly advised<br />

boom makes the T 540 stand out<br />

from its competitors. With our<br />

new T 540, we are now the only<br />

rental company in Denmark<br />

with a truck-mounted platform<br />

with a outreach of 40 m. This<br />

gives us a real competitive<br />

advantage.”<br />

| 10

GLOBAL NEWS<br />

The Netherlands<br />

Kamphuis takes delivery of 2 HEIGHT performance-STEIGER ®<br />

– one with HYBRIDpower<br />

Our long-standing customer<br />

– Kamphuis – has just taken<br />

delivery of a HEIGHT<br />

performance-STEIGER ® T 480<br />

and T 720.<br />

Kamphuis is one of the leading<br />

aerial work platform rental<br />

companies in the Netherlands.<br />

The well-known company added<br />

the very first STEIGER ® T 540 to<br />

its fleet in 2013. Because this<br />

model has performed so<br />

brilliantly, the company decided<br />

to order a T 480 and T 720 as<br />

well.<br />

The HEIGHT performance-<br />

STEIGER ® T 720 that Kamphuis<br />

Poland<br />

ordered, is equipped with<br />

HYBRIDpower.<br />

The illustrated T 720 and the<br />

T 480 are naturally equipped<br />

with all the technical, typical and<br />

useful features which all other<br />

models of the HEIGHT performance<br />

STEIGER ® offer as well.<br />

For example, a long upper boom<br />

with movable RÜSSEL ® (jib), the<br />

biggest working basket in its<br />

class, a support/ outrigger<br />

control from two control units<br />

at the vehicle rear side and a<br />

second control unit in the<br />

working basket.<br />

CITY-STEIGER ® TU 285 for Warsaw<br />

The handover of the HEIGHT performance-<br />

STEIGER ® duo. RUTHMANN Area Sales Manager,<br />

Bernd Wiesmann (on the left) is happy to hand<br />

over both models to Emiel Kamphuis (on the right).<br />

Mr. Kamphuis is General Manager of Kamphuis<br />

Hoogwerkers Group.<br />

Further detailed information on<br />

the Hybridpower can be found in<br />

this magazine in the ‘Functions’<br />

category. •<br />

Beginning of November a<br />

CITY-STEIGER ® TU 285 started<br />

towards Poland. In Warsaw<br />

it will be handed over to the<br />

local working platform rental<br />

company Smielak. Everything<br />

is handled by our experienced,<br />

competent Polish Sales and<br />

Service partner “Windex” (from<br />

Chojnice).<br />

Our CITY-STEIGER ® TU 285<br />

offers a very special mix of<br />

excellent capacity data,<br />

combined with optimal<br />

technical equipment as well<br />

as very compact sizes.<br />

It will be as well soon in use in<br />

Warsaw at the working platform<br />

rental company Smielak: Our<br />

CITY-STEIGER ® TU 285. •<br />

(Centre and right) Andrzej Aszyk (owner and CEO of Windex) and Andre<br />

Gerdes (Area Sales Manager RUTHMANN) at the handover of the TU 285 in<br />

our factory in Gescher-Hochmoor.<br />

| 11

GLOBAL NEWS<br />

USA<br />

Blade Platforms USA relies on HEIGHT performance-STEIGER ®<br />

Our American sales and service partners TIME sold a RUTHMANN T 175 A * – mounted on a 4-axle<br />

Freightliner – to the American working platform rental company Blade Platforms. ( * corresponds to<br />

our HEIGHT performance-STEIGER ® T 540).<br />

to climbers who can take only<br />

very limited tools and materials<br />

on the rope. Alternatively, the<br />

scaffolding of a wind power<br />

plant is often economically<br />

inefficient.<br />

The RUTHMANN T 175 A corresponds to our HEIGHT performance-STEIGER ®<br />

T 540. Before the mounting works took place, the stage construction had been<br />

specially adapted for the North American market. So it fulfills, for example,<br />

ANSI (American National Standards Institute) standards which are valid in North<br />

America.<br />

The RUTHMANN T 175 A is part<br />

of a comprehensive shortmedium<br />

term Blade market<br />

strategy as the Rental Division of<br />

our partner time has rented<br />

another RUTHMANN T 175 A<br />

(on 3-axle Freightliner) to Blade<br />

Platforms.<br />

The professional truck-mounted<br />

platform is used primarily for<br />

maintenance works of wind<br />

turbines, carried out by Blade‘s<br />

own employees, alongside rental<br />

deployment.<br />

Ultimately, the Blade employees<br />

themselves gained such a positive<br />

impression of our working<br />

platform of a leased T 175 A<br />

during their work assignments,<br />

which now led to the purchase.<br />

For operations of wind turbines<br />

a very high stability, flexibility<br />

and maximum performance data<br />

are demanded by a truckmounted<br />

platform. These<br />

parameters are met with flying<br />

colors by the RUTHMANN T 175<br />

A. As with the other models of<br />

our HEIGHT performanceseries,<br />

the largest customer<br />

benefit with the T 175 A as well is<br />

the long outreach of the upper<br />

boom – in a very large working<br />

height.<br />

Furthermore, this truckmounted<br />

platform scores with a<br />

working basket load capacity of<br />

up to 600 kg, so that the<br />

“additional lifting” of tools and<br />

material is no problem for the<br />

RUTHMANN T 175 A. And the<br />

3.7 m² large working basket<br />

surface offers enough space for<br />

one or more craftsmen, the<br />

working platform operator and<br />

the required working material<br />

as well for their tools. These are<br />

decisive advantages compared<br />

Safe working on 3.7 square meters –<br />

currently the largest working basket<br />

in the industry – 3.82 m x 0.97 m –<br />

allows craftsmen or technicians comfortable<br />

working at dizzy heights. And<br />

the 600 kg working basket load can<br />

carry even heavy material to the site.<br />

| 12

GLOBAL NEWS<br />

Based on the good experiences<br />

with the T 175 A (T 540), Blade<br />

Platforms decided for the T 235 A<br />

as well. The T 235 A (T 720) was<br />

shipped as kit version to the<br />

USA and was mounted on a<br />

Kenworth 5-axis-chassis at<br />

TIME Manufacturing in Texas.<br />

Blade Platforms provides truckmounted<br />

working platforms<br />

with a working height of 54 m to<br />

103 m for rent in throughout<br />

North America. More<br />

information about Blade<br />

Platforms can be found at:<br />

www.bladeplatforms.com •<br />

RUTHMANN T 235 A<br />

Belgium<br />

RUTHMANN counts on HDW Belux in Belgium<br />

HDW Belux is our new sales and service partner for our STEIGER ® range in Belgium. This step was<br />

necessary and practical after HDW Nederland acquired BV TIME Benelux - our previous Belgian sales<br />

and service partner. The new company has been renamed HDW Belux. Sales and service of our<br />

STEIGER ® are thus now located in Tienen, Belgium - where TIME Benelux had to date a depot.<br />

HDW has taken over the<br />

complete TIME Benelux<br />

workforce to guarantee the<br />

continuation of technical and<br />

commercial know-how and thus<br />

to continue to fulfil customer<br />

wishes and needs to the utmost<br />

satisfaction,<br />

HDW has been successful as<br />

Genie distributor in the aerial<br />

working platform world for over<br />

30 years, including large parts of<br />

Eastern Europe and the Benelux<br />

countries. In addition, HDW also<br />

distributes truck-mounted lifts<br />

of the Italian brand Isoli and<br />

Teupen spider lifts. And in<br />

addition to this - VERSALIFT ®<br />

lifts since last year as well.<br />

Further information can be<br />

found at: www.hdwnl.com/en •<br />

Furthermore, the HDW Belux<br />

team will be reinforced with the<br />

addition of Mike Van den Bosch<br />

who will be responsible for all<br />

commercial activities for<br />

RUTHMANNSTEIGER ® as well.<br />

| 13

GLOBAL NEWS<br />

Spain<br />

AMCO is our export partner of the year<br />

Over the past 5 months, our representative in Spain has been “firing on all cylinders”.<br />

We are continuously expanding<br />

our worldwide dealer and<br />

service network. In Spain,<br />

AMCO Machinery & Consulting<br />

has been responsible for the<br />

sales and service activities of<br />

RUTHMANNSTEIGER ® aerial<br />

work platforms since the middle<br />

of the year. AMCO has been so<br />

successful in marketing our<br />

STEIGER ® brand in such a short<br />

period of time that it has now<br />

been named ‘2015 Sales and<br />

Service Partner of the Year.’<br />

With this annual award,<br />

RUTHMANN recognizes the<br />

outstanding achievements of its<br />

representatives in other<br />

countries.<br />

Compared to other worldwide<br />

sales and service partners,<br />

AMCO provided RUTHMANN<br />

with the highest volume of<br />

incoming orders.<br />

The jury was also impressed<br />

with how quickly and<br />

professionally AMCO<br />

implemented the jointly agreed<br />

upon milestones for a successful<br />

partnership. From<br />

communicating over the<br />

internet, in trade magazines, and<br />

newsletters to conducting<br />

customer visits and<br />

demonstrations, AMCO has<br />

been successful at every level. It<br />

is safe to say that AMCO is<br />

responsible for the rapid and<br />

incredible sales performance we<br />

enjoy in Spain today.<br />

The highly efficient sales and<br />

service partners play a key role<br />

in the level of success that we<br />

enjoy around the world today.<br />

Strong, local sales partners are<br />

close to the customer because<br />

they speak the language and are<br />

familiar with the local customs<br />

and business practices. They<br />

know the right marketing<br />

strategies for RUTHMANN<br />

products and provide excellent<br />

advice and after-sales service to<br />

foreign customers.<br />

Uwe Strotmann made the<br />

following comment: “We are<br />

extremely pleased with the<br />

successful start we have had<br />

with AMCO and will soon be<br />

reporting on further deliveries<br />

of our STEIGER ® work platforms<br />

to customers in Spain.”<br />

AMCO Machinery & Consulting<br />

is a Spanish company under<br />

German management and is<br />

based in Gijon. The focus<br />

through expert knowledge is on<br />

the international marketing of<br />

mobile and caterpillar cranes as<br />

well as working platforms and<br />

second-hand machines. The<br />

company advises its global<br />

customer base within the AMCO<br />

Asset Management with<br />

globalisation and expansion<br />

projects, fleet configurations,<br />

export/import and creating<br />

machine evaluations. •<br />

This year, RUTHMANN’s International Sales & Service Partner Meeting – held<br />

on November 6, 2015 – was accompanied by a traditional and very lively<br />

Oktoberfest celebration. The nominees for the ‘Sales and Service Partner of<br />

the Year Award’ were announced during the festivities. Bert Wiegel – General<br />

Manager of AMCO Machinery and Consulting – was proclaimed winner of this<br />

prestigious award.<br />

| 14

FEATURES<br />

HYBRIDpower<br />

Green power for more possibilities.<br />

Our HEIGHT performance-<br />

STEIGER ® can now be equipped<br />

with HYBRIDpower as well. It<br />

features an additional battery<br />

pack/electric motor for extremely<br />

quiet and emission-free<br />

operation. When working in<br />

pedestrian zones or inside<br />

enclosed/partially enclosed<br />

buildings, HYBRIDpower is by<br />

far the most sensible solution.<br />

With HYBRIDpower, we fulfill<br />

customer wishes for ecological<br />

and also economical propulsion<br />

alternatives for our STEIGER ®<br />

truck-mounted aerial work<br />

platforms. HYBRIDpower by<br />

RUTHMANN saves diesel fuel<br />

because the vehicle’s engine<br />

does not need to be running<br />

during the few boom<br />

movements in the air/at the<br />

object. Here, the STEIGER ® can<br />

be operated with battery power<br />

only. Since the vehicle does not<br />

have to be started up/shut down<br />

as often, there is also less engine<br />

wear.<br />

Furthermore, should the<br />

vehicle’s engine malfunction<br />

during operation (with the<br />

boom high off the ground),<br />

HYBRIDpower by RUTHMANN<br />

also serves as a very practical<br />

emergency backup motor. •<br />

| 15

FEATURES<br />

Movement rediscovered<br />

New milestone set with “RUTHMANNCOCKPIT”<br />

At the Platformers‘ Days trade<br />

show, we unveiled our new,<br />

ultra-modern control panel,<br />

known as the “COCKPIT”. The<br />

full-colour graphic display,<br />

clearly arranged keys, and<br />

functional joysticks set new<br />

standards in operational<br />

convenience.<br />

Menu buttons<br />

Customer benefits are a<br />

number one priority for us at<br />

RUTHMANN. Our company<br />

has been developing and<br />

programming our own<br />

sophisticated control technology<br />

for decades. Continuously<br />

optimized STEIGER ® controls<br />

are safe, efficient, easy to<br />

operate, and backed by round<br />

the clock, 24/7, after-sales<br />

service. Our underlying<br />

principles, high-quality<br />

standards and expertise have<br />

also been incorporated in our<br />

new “COCKPIT” control panel.<br />

The ultra-modern “COCKPIT”<br />

features a clear design and an<br />

intuitive user interface. The keys<br />

are sturdy so that everything in<br />

the Cockpit can easily be<br />

handled with work gloves.<br />

In the upper area, the cockpit<br />

features a comprehensive<br />

information area with a<br />

full-colour graphic display.<br />

Hot keys<br />

Here, there is space for up to<br />

7 hot keys that control specific<br />

STEIGER ® functions. Boom<br />

positions, for example, can be<br />

saved and floodlights on the<br />

basket (optional) can be<br />

switched on and off. There are<br />

also 10 additional menu buttons<br />

in the upper display area that<br />

enable operators to retrieve<br />

important vehicle information,<br />

terrain conditions, boom<br />

positions, and operating<br />

instructions. The menu buttons<br />

are also used to retrieve<br />

important operational data from<br />

the STEIGER ® ’s information and<br />

diagnostic system.<br />

Depending on the model, the<br />

Cockpit is equipped with/<br />

without a graphic display. Two<br />

pre-installed (230 V and 24 V)<br />

sockets are standard equipment.<br />

The many additional features<br />

optionally available can also<br />

be retrofitted.<br />

Three different display modes<br />

adjust brightness to ensure<br />

good readability in all lighting<br />

conditions – during the day,<br />

at night or in bright sunlight.<br />

Every key is backlit and has a<br />

status LED that indicates the<br />

switching status.<br />

| 16

FEATURES<br />

In the lower part of the control<br />

panel, the joysticks and<br />

ergonomic hand rest ensure<br />

relaxed and sensitive navigation<br />

of the work platform. This<br />

guards against operation/<br />

accidental misuse. 16 centrally<br />

configured function keys with<br />

familiar icons facilitate efficient<br />

and safe operation of many<br />

different control functions.<br />

These include the automatic<br />

retraction mechanism,<br />

automatic positioning of<br />

outriggers, and switching the<br />

vehicle engine on and off.<br />

The new modular Cockpit is<br />

extremely user-friendly.<br />

All components can quickly<br />

be replaced individually without<br />

any degree of difficulty. •<br />

| 17

FEATURES<br />

Bird‘s-eye view<br />

The view around<br />

Everyone who considers safety and operational<br />

effectiveness as an important feature should equip<br />

their STEIGER ® with a “bird’s-eye view”. The 360°<br />

camera system displays everything in the driver’s<br />

cabin that is happening around your STEIGER ® .<br />

As well from the bird’s-eye view. To this effect,<br />

four cameras are mounted to the vehicle and<br />

telescopic boom. One at the front of the cooling<br />

grill (see below), one to the left and to the right on<br />

the boom and one at the rear of the vehicle rear.<br />

As demonstrated on the left, the bird’s-eye view<br />

system can represent every camera individually<br />

on the screen. The system offers the possibility to<br />

position, for example, the supports thanks to the<br />

all-round view without incurring any greater<br />

danger. This then, for example, prevents that<br />

objects can be damaged or leant on manhole<br />

covers. •<br />

Camera in the front<br />

| 18

PEOPLE<br />

RUTHMANN competence: structural stability and safety<br />

Professional expert, Dr. Eng. Robert Krause has been stability analyst on RUTHMANN’s highly<br />

motivated and top-performing design team since March, 2014.<br />

Dr. Eng. Krause is a civil<br />

engineer specialization in<br />

modeling and simulation<br />

techniques. He is 31 years old,<br />

married and has two children.<br />

Robert Krause earned his<br />

doctorate degree in Simulation<br />

Technology from the University<br />

of Stuttgart (Clusters of<br />

Excellence) in November, 2014.<br />

At RUTHMANN, stability, functionality,<br />

and uncompromising<br />

safety are top priorities. Robert<br />

Krause conducts appropriate<br />

stability analysis/calculations in<br />

order to assure that every<br />

STEIGER ® leaves the factory<br />

with the perfect security<br />

settings/configurations. He<br />

calculates the working range of<br />

a truck-mounted aerial work<br />

platform by taking into account<br />

their stability and load capacity.<br />

“I have had a soft spot for truckmounted<br />

aerial work platforms<br />

for as long as I can remember,”<br />

Dr. Eng. Robert Krause admitted.<br />

“After reading RUTHMANN‘s<br />

job posting, I knew that this<br />

would be the perfect opportunity<br />

for me. Working for the marketleading<br />

work platform<br />

manufacturer allows me to<br />

indulge my fascination while<br />

maximizing operational safety at<br />

the jobsite.”<br />

“As the most competent work<br />

platform manufacturer in the<br />

industry, RUTHMANN is now<br />

extremely well positioned. All of<br />

my experience and motivation<br />

goes into improving what is<br />

already good. I am constantly<br />

engaged in system optimization/<br />

development analysis in order<br />

enhance the working range of<br />

our machinery without<br />

compromising the extremely<br />

high safety standards that<br />

RUTHMANN<br />

is so famous<br />

for”, Robert<br />

Krause<br />

explained.<br />

Design and<br />

Development<br />

Manager –<br />

Dr. Nico<br />

Krekeler – has<br />

tremendous<br />

confidence in<br />

his colleague’s<br />

capabilities.<br />

“Dr. Krause<br />

has<br />

established<br />

himself as a key member of the<br />

team. I appreciate his profound<br />

knowledge, experience, and<br />

perspectives. We both share the<br />

same fascination with truckmounted<br />

aerial work platforms.<br />

Our mutual goal is to provide<br />

true customer value/benefits<br />

and wow our customers with<br />

innovative technology and<br />

creative design.” •<br />

| 19

PEOPLE<br />

Dr. Eng. Nico Krekeler earns his doctorate degree<br />

Dr. Eng. Nico Krekeler has been awarded his<br />

doctorate degree – RUTHMANN’s Product Design<br />

and Development Manager for the past 6 years.<br />

He has successfully completed his Doctor of<br />

Engineering (Dr. Eng.) degree.<br />

He earned his doctorate in the field of tribology<br />

which includes the study and application of the<br />

principles of friction, lubrication and wear. His<br />

expertise lies primarily in reducing abrasive wear<br />

through extensive testing carried out on chassis<br />

suspension joints in the axle assembly.<br />

Prior to joining RUTHMANN, Dr. Eng. Krekeler<br />

studied Mechanical Engineering at Ruhr University<br />

in Bochum. As a postgraduate student from 2005 to<br />

2009, he worked with Arbeitsgruppe Baumaschinentechnik (BMT) – a research group for construction<br />

equipment technology – where he was involved with tribo-mechanical system simulation.<br />

Congratulations, Dr. Eng. Krekeler on this tremendous achievement. At age 34, your future looks very<br />

bright indeed. •<br />

Top positions in the city run<br />

The traditional city run through downtown Coesfeld on October 10, 2015, was back again on the agenda.<br />

We started with 32 employees and are again very happy about top rankings, especially with the individual<br />

and relay runners.<br />

Thomas Schneider, for example,<br />

reached second place in the<br />

10 km run, in the age group male<br />

50+.<br />

The best RUTHMANN relay was<br />

in the final on position 4. This<br />

was a great success all around!<br />

Congratulations! •<br />

| 20

PEOPLE<br />

Driver safety training<br />

We live our slogan “professionals at work”;<br />

naturally this also applies to road traffic.<br />

That is why many employees participated in the<br />

ADAC (General German Automobile Association)<br />

driver safety training in Haltern.<br />

Our employees learned to understand the<br />

behavior and the limits of their cars under<br />

professional guidance during the classic<br />

full-day training course at the standard-equipped<br />

training facilities. They were taught driving<br />

techniques so to be able to react correctly in<br />

case of emergency. •<br />

Dragon Boat Cup in Münster - Our team is paddling from the front!<br />

The city harbor of Münster was<br />

transformed into a Dragon Boat<br />

stadium during the 1st Dragon<br />

Boat Cup “In|du * |strie”. 33 paddle<br />

teams showed great attitude:<br />

team spirit, the will to win and a<br />

lot of pleasure in the sports<br />

event.<br />

Everyone knew that we are<br />

sitting in one boat - regardless<br />

whether at work or at sports - as<br />

success is based on teamwork.<br />

We were proud to be a part of<br />

this!<br />

26 RUTHMANN employees<br />

(RUTH MEN) paddled like true<br />

sportsmen with great enthusiasm<br />

and team spirit, reaching<br />

second place in the “Sports”<br />

category. The cash prize of<br />

500 € was donated to<br />

the local sports club<br />

SUS Hochmoor. •<br />

*<br />

(Remark: “DU” means “you”)<br />

| 21

NEW PRODUCTS<br />

Solid as a Rock<br />

RUTHMANNSTEIGER ® T 360<br />

“Solid as a rock” is how we describe our T 360. The slogan epitomizes our powerful, sturdy, and<br />

compact model designed for truck chassis with a gross vehicle weight rating (GVWR) of 15 t or more.<br />

35 m class –<br />

performance<br />

newly defined<br />

With the T 360, we offer customers<br />

a modern alternative in the 35 m<br />

truckmounted aerial work<br />

platform category. Its impressive<br />

performance capabilities include<br />

the 31 m lateral outreach and<br />

almost 360 degree circular range<br />

of motion (100 kg basket load).<br />

Compared to older STEIGER ®<br />

models and competitor brands,<br />

T 360 operators now have an<br />

extra 2.3 m of additional reach<br />

capacity at their disposal. The<br />

short overall length of 9.47 m<br />

combined with a height of 3.77 m<br />

and short 4.7 m (and up)<br />

wheelbase, are further reasons<br />

why the T 360 is the perfect<br />

replacement investment for older<br />

work platforms in the 35 m<br />

category. The impressive 600 kg<br />

payload reserves of this<br />

professional work platform is an<br />

added advantage. A wide range of<br />

optional equipment – box bodies<br />

for necessary tools and materials,<br />

cab covers, LED marker lights,<br />

aluminum platform gates, work<br />

basket guard rails, etc. – is<br />

available without exceeding the<br />

gross vehicle weight rating<br />

(GVWR).<br />

Top performance<br />

data for professional<br />

applications<br />

| 22

NEW PRODUCTS<br />

Our T 360 has a lot of sophisticated<br />

standard equipment. This<br />

includes the fully variable support<br />

mechanism. Depending on<br />

the position of the individual<br />

outrigger, our state-of-the-art<br />

electronic control system enables<br />

dynamic range adaption for<br />

maximum operational safety and<br />

efficiency. Outriggers can be<br />

activated using the controls<br />

located at rear on both sides of<br />

the vehicle, from the alternate<br />

control on the passenger side,<br />

and from the control panel in<br />

the work basket.<br />

The automatic set-up/retraction<br />

mechanism and 5° permissible<br />

inclination are also standard<br />

features on this professional<br />

truck-mounted aerial work<br />

platform. Operators are able to<br />

carry out assignments on sloped<br />

and uneven surfaces with<br />

utmost safety and efficiency.<br />

flexible RÜSSEL ® ,<br />

versatile working<br />

basket<br />

The working basket on the T 360<br />

is an excellent place to work. In<br />

addition to the full 350 kg load<br />

capacity, it also comes with an<br />

interchangeable basket system.<br />

Depending on the assignment,<br />

operators can use the standard<br />

aluminium (1.7 m x 0.86 m)<br />

basket or other optional work<br />

baskets. These include the extra<br />

wide (2.1 m x 0.86 m) work<br />

basket, the narrow tree cutting<br />

basket, or the synthetic basket.<br />

The insulated synthetic basket<br />

and standard “boom to chassis”<br />

insulation allow assignments to<br />

be carried out on live (up to<br />

1000V) power lines.<br />

Uncompromising safety,<br />

stability, and functionality are<br />

top priorities for RUTHMANN.<br />

That is why the T 360 also<br />

comes equipped with a solid<br />

5-section telescoping boom<br />

The impressive reach with 31m is the trademark of the new<br />

STEIGER ® T 360.<br />

A circular working area (when looking from a bird’s-eye view)<br />

shows the possible applications for height access professionals<br />

who place more emphasis on the working platform than on<br />

driving licence categories.

NEW PRODUCTS<br />

100 kg<br />

350 kg<br />

100 kg<br />

350 kg<br />

system and 185 degree swivelling<br />

jib (RÜSSEL ® ) made of ultrahigh<br />

strength, fine-grained steel.<br />

Compared to other models in<br />

the successful T Series, the jib<br />

(RÜSSEL ® ) and work basket<br />

console of the T 360 have been<br />

optimized to suit the specific<br />

needs of power utility<br />

companies and craftsmen.<br />

30,90 m<br />

350 kg<br />

30,90 m<br />

100 kg<br />

Modular control<br />

panel (Cockpit)<br />

The ultra-modern control panel<br />

in the work basket – known as<br />

the “Cockpit” – further<br />

enhances the level of<br />

technological perfection.<br />

The T 360 is EURO 6 compatible<br />

and there is a large variety of<br />

different truck makes and<br />

models to choose from.<br />

Customers can order 15 t and<br />

18 t (GVWR) or all-wheel drive<br />

chassis. All factors considered,<br />

our RUTHMANN STEIGER ®<br />

T 360 really is as “solid as a<br />

rock.” •<br />

30,90 m<br />

30,90 m<br />

| 24

NEW PRODUCTS<br />

STEIGER ® T 170<br />

Compact category on a 7.49 t chassis. Incredible adaptability!<br />

At the annual Platformers‘ Days trade show in Hohenroda (Germany) in September 2015 we presented<br />

the STEIGER ® T 170 for the first time. The T 170 is a particularly sturdy and compact all-rounder on a<br />

7.49 t chassis.<br />

Equipment rental companies,<br />

municipalities, power utility<br />

companies, and infrastructure<br />

development companies need<br />

truck-mounted aerial work<br />

platforms that are as versatile as<br />

possible. Our STEIGER ® T 170 is<br />

simply ideal. From street light,<br />

signal light, and overhead power<br />

line maintenance to treecutting/pruning<br />

assignments<br />

and installation work, the T 170<br />

is able to tackle the diverse jobs<br />

without any degree of difficulty.<br />

With a total vehicle length of<br />

7.48 m, height of 3.36 m and<br />

3.6 m wheelbase, the T 170 is<br />

extremely compact in size. It<br />

features a working height of 17<br />

m, lateral outreach of 12 m, and a<br />

circular range of motion (100 kg<br />

The STEIGER ® T 170, with its 17 m working height and 12 m<br />

lateral outreach, is both sturdy and compact and features a<br />

vertical support mechanism. The T 170 has sufficient load<br />

capacity for day-to-day operation and is mounted onto 7.49 t,<br />

Euro 6 chassis made by a variety of different manufacturers.<br />

basket load). These features,<br />

coupled with the 185° movable<br />

jib (RÜSSEL ® ), provide<br />

maximum versatility and agility<br />

at the jobsite.<br />

The impressive 600 kg load<br />

capacity of this professional<br />

work platform is an added<br />

advantage. A wide range of<br />

optional equipment – box<br />

bodies for necessary tools and<br />

materials, cab covers, LED<br />

marker lights, aluminum<br />

platform gates, work basket<br />

guard rails, etc. – is available<br />

without exceeding the gross<br />

vehicle weight rating.<br />

The four hydraulic vertical<br />

support cylinders – attached<br />

directly to the base frame of the<br />

STEIGER ® – provide the<br />

necessary stability. For every<br />

assignment, the work platform<br />

is stabilized within the contours<br />

of the vehicle.<br />

General principle: If there is<br />

enough space for the truck, the<br />

STEIGER ® aerial platform will be<br />

able to carry out its assignment.<br />

This support mechanism is ideal<br />

when working in heavy traffic.<br />

Tasks on busy streets include<br />

street light and transformer<br />

maintenance and tree-cutting<br />

projects. Despite the “narrow”<br />

| 25

NEW PRODUCTS<br />

aluminium (1.7 m x<br />

0.86 m) basket or other<br />

optional work baskets.<br />

These include the extra<br />

wide (2.1 m x 0.86 m)<br />

work basket, the narrow<br />

tree cutting basket, or the<br />

synthetic basket. The<br />

insulated synthetic basket<br />

and standard “boom to<br />

chassis” insulation allow<br />

assignments to be carried<br />

out on live (up to 1000V)<br />

power lines.<br />

In addition, the T 170 is EURO 6<br />

compatible and can be mounted<br />

onto a great variety of different<br />

chassis/models including MAN,<br />

Mercedes-Benz, Volvo, and DAF.<br />

•<br />

Equipped with the optional synthetic work basket,<br />

the new STEIGER ® T 170 is able to carry out<br />

assignments on live power lines. The new<br />

“Cockpit” control panel facilitates easy and<br />

intuitive operation of the work platform.<br />

support feature, the powerful<br />

performance capabilities of the<br />

STEIGER ® T 170 are not<br />

restricted in any way.<br />

The work basket on the T 170 is<br />

an excellent place to work. In<br />

addition to the full 350 kg load<br />

capacity, it also comes with an<br />

interchangeable basket system.<br />

Depending on the assignment,<br />

operators can use the standard<br />

Uncompromising safety,<br />

stability, and functionality<br />

are top priorities for us.<br />

That is why this new<br />

model also comes<br />

equipped with a solid<br />

2-section telescoping<br />

boom system, turret, and<br />

jib (RÜSSEL ® ) made of<br />

ultra-high strength,<br />

fine-grained steel.<br />

Compared to other models in<br />

the successful T Series, the jib<br />

(RÜSSEL ® ) and work basket<br />

console have been optimized to<br />

suit the specific needs of power<br />

utility companies, municipalities,<br />

and craftsmen.<br />

The ultra-modern control panel<br />

in the work basket – known as<br />

the “Cockpit” – further<br />

enhances safety and facilitates<br />

ergonomic, fatigue-free<br />

handling.<br />

100 kg<br />

100 kg<br />

350 kg<br />

350 kg<br />

12,00 m<br />

12,00 m<br />

350 kg<br />

100 kg<br />

| 26<br />

Working height 17.00 m<br />

Lifting height<br />

15.00 m<br />

Outreach<br />

12.00 m<br />

Work basket size 1.70 x 0.86 m<br />

Work basket load capacity 350 kg<br />

Permissible inclination 5°<br />

Range of rotation 540°<br />

Total height ≥<br />

3.46 m<br />

Total length ≥<br />

7.48 m<br />

Permissible total weight ≥ 7,490 kg

NEW PRODUCTS<br />

SKYBIRD 215I<br />

TIME and RUTHMANN provide power<br />

Skybird 215I: perfect for work under live high-voltage power lines due to its high isolation and maximum<br />

performance specifications<br />

Skybird 215I<br />

A TIME and RUTHMANN creation.<br />

At the ICUEE (International<br />

Construction and Utility<br />

Equipment Exposition) which<br />

took place in Louisville,<br />

Kentucky from September 29<br />

– October 1, our collaborative<br />

partner – TIME Manufacturing<br />

– launched its brand new<br />

Skybird 215I. The new truckmounted<br />

aerial work platform,<br />

with its 66 m working height,<br />

is ideal for assignments on<br />

high-voltage power lines. When<br />

it comes to fully insulated work<br />

platforms, TIME has decades of<br />

experience. With the Skybird,<br />

TIME relies on the awardwinning<br />

technology of our<br />

HEIGHT performanceseries.<br />

The Skybird is the result of a<br />

collaborative effort between<br />

TIME and ourselves at<br />

RUTHMANN. For its part, we<br />

delivered a kit version of the<br />

STEIGER ®<br />

T 720 (known<br />

in North<br />

America<br />

as the<br />

RUTHMANN<br />

T 235 A). The<br />

special<br />

feature: the<br />

upper boom of<br />

this kit comes<br />

with an<br />

inner-lying<br />

telescoping<br />

1.85 m (6 ft.)<br />

section. A highly insulated upper<br />

boom (made of fibreglass) and<br />

work basket – specially<br />

developed in the USA by TIME<br />

Manufacturing – were then<br />

attached to our telescoping<br />

upper boom. The prototype of<br />

the Skybird 215I is mounted on a<br />

6-axle, Freightliner 114SD<br />

Twinsteer chassis. With this<br />

truck-mounted aerial lift,<br />

specially trained workers are<br />

able to carry out assignments on<br />

high-voltage power lines of up<br />

500 kV without any degree of<br />

difficulty.<br />

The Skybird 215I made quite an<br />

impression on industry experts<br />

at ICUEE 2015. The approx. 66 m<br />

(215 ft.) working height and 32 m<br />

(105 ft.) lateral outreach (at<br />

100 kg basket load) are two<br />

defining characteristics of this<br />

fully insulated truck-mounted<br />

aerial work platform.<br />

When it comes to working on<br />

high-voltage power lines, TIME<br />

Manufacturing has years of<br />

experience. For this reason,<br />

both companies have agreed to<br />

market the Skybird globally<br />

under TIME’s well known<br />

Versalift brand name. Both<br />

manufacturers see a huge<br />

worldwide potential because<br />

regular maintenance and repair<br />

work on power lines will<br />

minimize electric power<br />

disruptions everywhere. •<br />

Top performance for assignments<br />

on high-voltage power lines<br />

The Skybird features a working height<br />

of approx. 66 m and lateral outreach<br />

of 32 m. Its telescoping upper boom<br />

has incredible reach capacity when<br />

working up high. The Skybird able<br />

to manoeuvre around objects with<br />

utmost sensitivity and precision. It is<br />

ideal for assignments on high-voltage<br />

transmission towers/ electricity masts.<br />

| 27

SERVICE<br />

RUTHMANN: New SERVICEpoint in Ruhr region<br />

In order to further optimize our extensive service network across Germany, we have established an<br />

additional “SERVICEpoint” in the Ruhr region. Our nationwide presence and professional service<br />

personnel provide the best on-site service in the industry.<br />

Dirk Döhring has years of<br />

experience in the aerial work<br />

platform industry. Effective<br />

immediately, Mr. Döhring will be<br />

providing competent, reliable,<br />

and prompt mobile service to<br />

customers in the Ruhr region.<br />

His service vehicle is a mobile<br />

workshop, equipped with the<br />

necessary spare parts and technical<br />

documentation. This allows<br />

Dirk Döhring to carry out safety<br />

inspections, maintenance, and<br />

minor repair work on STEIGER ®<br />

and VERSALIFT ® aerial work<br />

platforms as well as on makes<br />

and models of other<br />

manufacturers. He does his<br />

work directly on the customer’s<br />

premises.<br />

Faster response times and<br />

mobile application possibilities<br />

provide major advantages. Our<br />

“SERVICEpoints” are extremely<br />

cost-effective as they minimize<br />

downtime and costly<br />

transportation costs.<br />

“SERVICEpoint Ruhr”, is part<br />

of our company-owned service<br />

centre in Gescher-Hochmoor.<br />

Dirk Döhring’s work<br />

assignments are dispatched<br />

from here. More extensive<br />

repair work, inspections, and<br />

maintenance tasks will continue<br />

to be carried out in<br />

Gescher-<br />

Hochmoor.<br />

Our steadily<br />

expanding<br />

after-sales<br />

service<br />

network not<br />

only reflects<br />

the evergrowing<br />

demand in our<br />

service<br />

division but<br />

also the<br />

continuous<br />

growth of our<br />

company.<br />

Neuss<br />

Mönchengladbach<br />

Düren<br />

Dinslaken<br />

A42<br />

Oberhausen<br />

Gelsenkirchen<br />

Essen<br />

Moers<br />

A40 Bochum<br />

A57<br />

Krefeld<br />

A46<br />

Grevenbroich<br />

Bergheim<br />

A4<br />

Duisburg<br />

A44<br />

Düsseldorf<br />

A61<br />

A57<br />

A1<br />

Rhein<br />

Brühl<br />

Wherever they are, our<br />

customers can rely on our<br />

competent and reliable service<br />

at all times.<br />

Our efficient service network<br />

comprises more than 90<br />

experienced and highly qualified<br />

service employees. Through<br />

professional training and<br />

continuing education, we invest<br />

heavily in the technical<br />

competence of our staff. Topquality<br />

service is ensured. •<br />

A52<br />

Region of SERVICEpoint Ruhr<br />

A59<br />

Köln<br />

A3<br />

Leverkusen<br />

Wuppertal<br />

A46<br />

Remscheid<br />

Bergisch<br />

Gladbach<br />

A59<br />

A3<br />

Bonn<br />

A43<br />

A1<br />

Siegburg<br />

Dortmund<br />

A4<br />

Hagen<br />

Lüdenscheid<br />

Gummersbach<br />

A45<br />

A44<br />

Iserlohn<br />

Olpe<br />

Siegen<br />

| 28

SERVICE<br />

1 st WORKING PLATFORM SEMINAR<br />

Combined tree-trimming competency<br />

The first Working Platform Seminar took place on 01.10.2015 at our company headquarters. The focus<br />

was on tree trimming with aerial working platforms.<br />

We had invited the tree-cutting industry to this specialised seminar that offered a wide range of<br />

presentations. Top-class delegates came to Gescher-Hochmoor, such as large pan-German renters<br />

and professional tree cutters. The industry was very well represented at this event.<br />

Our conference room was well filled during the first<br />

Working Platform Seminar. Established tree trimming<br />

experts had participated.<br />

Mr Böcker, CEO of Stöteler Baumdienst GmbH, gave the<br />

participants an interesting insight in when at Stöteler what<br />

kind of working platform is used in pruning.<br />

The schedule was full to the brim. Thomas<br />

Bennemann (Service Manager at RUTHMANN)<br />

greeted the guests on behalf of the entire<br />

workforce. Once Uwe Stapper (RUTHMANN CFO)<br />

had introduced the company, the first<br />

presentation of the day was underway. Mr. Herr<br />

Böcker, Managing Director of Stöteler Baumdienst<br />

GmbH, explained the use of working platforms for<br />

tree trimming within his company. The focus lay<br />

here in the special features when choosing the<br />

right working platform and how exactly these fit<br />

for the individual, various work locations.<br />

Mr. Schaffner from IPAF was the next to present a<br />

good 45 minutes later. His subject matter: Security<br />

when working with mobile aerial working<br />

platforms. Roger Schaffner introduced the current<br />

IPAF project on security during tree cutting –<br />

something that was also initiated by us. He was<br />

able to report on fascinating real-life details from<br />

his long-standing experience as working platform<br />

operator and expeditor at a rental company.<br />

After that the participants had time to stretch<br />

their legs. Together with the speakers, they got to<br />

IPAF, the International Powered Access Federation (IPAF),<br />

globally promotes the secure and effective use in the<br />

powered access industry. Roger Schaffner attended as<br />

representative of this organisation and also shared much<br />

practical experience with the participants.

SERVICE<br />

see our manufacturing capabilities during a<br />

company tour – in pure sunshine. Test drives in<br />

various STEIGER ® -models were then available.<br />

The presentations continued after lunch. The<br />

leader and founder of the Institute for Tree<br />

Trimming, Prof. Dr. Dirk Dujesiefken,<br />

Uwe Böckmann from the Social Insurance for the<br />

Agriculture, Forestry and Horticulture (SVLFG) also gave an<br />

insight on the DGUV information 203-033 – pruning near<br />

to electric transmission lines.<br />

Norbert Schütz and Heiko Krauter from<br />

SüdLeasing GmbH then introduced the principle<br />

of financing and the value of working platform<br />

leasing for companies. The final item on the<br />

agenda then rounded off the day.<br />

The chance to “talk shop”, network and learn about the<br />

latest on working platform production technology all stood<br />

on the agenda between the breaks and the factory tour.<br />

unfortunately had to cancel at the last minute<br />

due to illness and was represented by his<br />

colleague Klaus Schröder. The peculiarities of<br />

tree roots were explained and how they behave<br />

in various subsoils and circumstances.<br />

The following presentation returned to the<br />

heights: the title being “Tree trimming work near<br />

to electric power lines/overhead wires”. Uwe<br />

Böckmann from the Social Insurance for the<br />

Agriculture, Forestry and Horticulture presented<br />

here. He explained the right use of tools such as<br />

telescopic saws and working platforms for tree<br />

trimming and referred to the guidelines of the<br />

German employers’ liability insurance association.<br />

By the way: the breaks were made full use of for<br />

networking.<br />

Our Innovation Manager Markus Jöhren brought<br />

the participants together in a small workshop. The<br />

audience then could render their wishes and ideas<br />

for an even simpler and safer way of working with<br />

working platforms for tree trimming. A very<br />

constructive discussion with an inspiring<br />

exchange of opinions on the workshop theme<br />

rounded off a successful first seminar event.<br />

The Working Platform Seminar will be repeated<br />

due to the relevance of its subject matter and the<br />

strong demand.<br />

Furthermore, we plan more seminars on practical<br />

themes from the world of working platforms! •<br />

The mood was buoyant amongst the participants.<br />

Roger Schaffner from the IPAF in open and friendly<br />

discourse with Markus Jöhren (right). Innovation<br />

Manager at RUTHMANN.<br />

Markus Jöhren led an interactive workshop amongst<br />

delegates after the presentations had been completed.<br />

The aim of this workshop: to collate ideas to further<br />

improve the efficiency and safety in tree trimming.<br />

| 30

Review<br />

MAXPO, Hyvinkää, Finland (10 th - 12 th September, 2015)<br />

EXHIBITIONS<br />

Our Finnish Sales and Service<br />

Partner Talhu Oy can look back<br />

on four successful days. In spite<br />

of the general poor economic<br />

situation in Finland, Talhu Oy<br />

draws an overall positive Maxpo<br />

fair conclusion. Talhu Oy<br />

returned from the “MAXPO”<br />

with many new contacts and<br />

specific enquiries.<br />

Our innovative CITY-STEIGER ®<br />

TU 285, the 3.5 t star TB 270+<br />

and the HEIGHT performance-<br />

STEIGER ® T 630 were on show.<br />

The “MAXPO” is a Finnish<br />

construction machine &<br />

construction vehicle<br />

demonstration show which took<br />

place this year from September<br />

10 th to 12 th , 2015 at the airfield<br />

Hyvinkää, 40 kilometres north of<br />

Helsinki. Talhu Oy was the only<br />

exhibitor of truck-loaded<br />

working platforms. •<br />

Platformers‘ Days, Hohenroda, Germany (11 th - 12 th September, 2015)<br />

The Platformers’ Days brought<br />

great successes for us. Our trade<br />

fair team returned with a dozen<br />

new orders and many specific<br />

enquiries for our products from<br />

the traditional work platform<br />

event in Hohenroda (in the<br />

German state of Hessen).<br />

Alongside this, we could again<br />

exchange ideas with a lot of<br />

existing and potential customers<br />

as well as with interested<br />

parties.<br />

“The high number of visitors as<br />

well as the interest in our<br />

products and especially the<br />

decisiveness of the trade fair<br />

visitors surpassed our<br />

expectations completely. It<br />

shows as well that we are able to<br />

meet the expectations of the<br />

market/ customers with our<br />

current STEIGER ® range.<br />

Punctual deliveries as well as<br />

our first-class after-salesservice<br />

complete the current<br />

RUTHMANN package”,<br />

comments Uwe Strotmann<br />

(General Sales Manager<br />

RUTHMANN) on the success<br />

of the fair.<br />

Our STEIGER ® innovations T 170<br />

and T 360, which debuted in<br />

Hohenroda, had an excellent<br />

start as well. Contracts for some<br />

units of the T 360 were already<br />

signed during the fair.<br />

A big thank to all who visited us<br />

in Hohenroda. •<br />

| 31

EXHIBITIONS<br />

Review<br />

Energetab, Bielsko-Biala, Poland (15 th - 17 th September, 2015)<br />

The Energetab trade show –<br />

held in Bielsko-Biala (Poland)<br />

from the 15 th - 17 th of September<br />

– has just ended. This annual<br />

event focuses on the energy<br />

sector and is therefore also an<br />

important venue for the aerial<br />

work platform industry.<br />

Of course, our competent, longtime<br />

Polish sales and service<br />

partner – Windex – was also on<br />

location once again this year.<br />

Windex presented the STEIGER ®<br />

TBR 220 and our brand new<br />

STEIGER ® T 360.<br />

The amazing, 31 m reach<br />

capacity (with 100 kg basket<br />

load) is what sets the STEIGER ®<br />

T 360 apart from the rest.<br />

The T 360 is designed for truck<br />

chassis starting at 15 t (GVW).<br />

The total vehicle length of this<br />

sturdy and compact all-rounder<br />

is only 9.47 metres. The height<br />

is a mere 3.77 metres. The new<br />

T 360 also has an impressive<br />

600 kg load capacity.<br />

For photos and additional<br />

information on the new<br />

STEIGER ® T 360, click here.<br />

The Energetab trade show was a<br />

huge success. Existing customer<br />

relationships were maintained<br />

and many new contacts were<br />

established. Windex was also<br />

very encouraged by the amount<br />

of new contracts initiated. •<br />

GIS, Piacenza, Italien (1 th - 3 rd Oktober, 2015)<br />

Under the name GIS - Giornate<br />

Italiane del Sollevamento - the<br />

5 th edition of the so-called<br />

„Italian Height Access Days“<br />

took place in Piacenza (Italy)<br />

during October 1 st - 3 rd , 2015.<br />

130 companies showed with<br />

their products and services<br />

from the range „height access<br />

and lifting equipment“. This<br />

event was very well attended<br />

with more than 6,000 visitors.<br />

Our long-standing Italian sales<br />

and service partner TRUCS also<br />

exhibited there and draws a<br />

thoroughly positive conclusion.<br />

The exhibition was a great<br />

success for our partner.<br />

The exhibition portfolio at the<br />

booth of TRUCS included our<br />

HEIGHT performance-STEIGER ®<br />

T 480, the CITY-STEIGER ®<br />

TU 285 as well as our 3.5-t star<br />

TB 270+. •<br />

| 32

Pictured is the RUTHMANNCARGOLOADER ® RCP 75.<br />

The RCP 75 has a huge 3,260 kg payload capacity.<br />

With a GVW of 7,490 kg, it can be operated by car<br />

driving licence holders with a class 3/C1 driving licence.<br />

CUSTOMER STORY<br />

Ideal for beverage retailers/distributors<br />

RUTHMANNCARGOLOADER ® RCP 75<br />

More and more beverage shops are taking advantage of our creative transport solutions by using a<br />

single CARGOLOADER ® vehicle to look after their daily logistics needs. Transporting beverages/<br />

empty bottles, items for special events, packaging, waste, etc. is incredibly easy and convenient with<br />

the CARGOLOADER ® .<br />

In addition to their main line of<br />

business – the sale of beverages<br />

– many retailers/distributors<br />

have also become event<br />

professionals at city, town, and<br />

club festivals. Responsibilities<br />

include the delivery, setting up,<br />

and dismantling of tents, serving<br />

guests/event visitors, removing<br />

empty bottles, and even waste<br />

removal. Our CARGOLOADER ®<br />

is perfect for all of these tasks.<br />

The catchphrase for safe, fast,<br />

and efficient beverage logistics:<br />

RUTHMANNCARGOLOADER ®<br />

“container hopping”.<br />

The cargo areas/containers on<br />

our CARGOLOADER ® ’s can be<br />

lifted and lowered within seconds.<br />

This is a standard feature<br />

that provides tremendous benefits.<br />

At the push of a button, the<br />

cargo area/container can be<br />

lowered parallel to the ground<br />

or raised to a height of 1.6 m.<br />

The lifting/lowering function<br />

facilitates fast, safe and<br />

ergonomic loading/unloading of<br />

the entire cargo area regardless<br />

of the loading conditions which<br />

tend to vary greatly.<br />

Raising and lowering wobbly tail<br />

lifts is now a thing of the past.<br />

| 33

CUSTOMER STORY<br />

items (such as fully loaded euro<br />

pallets) can easily be loaded/<br />

unloaded by one person using<br />

either a hand or electric low-lift<br />

pallet truck.<br />

This saves time and personnel<br />

– a major advantage for every<br />

beverage retailer/distributor,<br />

especially during busy periods.<br />

Cargo areas/containers on the CARGOLOADER ® can be exchanged quickly and easily.<br />

This feature saves time and personnel. While one employee unloads and reloads one<br />

container, the CARGOLOADER ® ‘s driver can take care of the next assignment with<br />

another container.<br />

Cargo areas/containers in<br />

CARGOLOADER ® vehicles can<br />

easily be exchanged.<br />

Our extremely creative<br />

interchangeable loading system<br />

provides a great variety of setup<br />

options and application<br />

possibilities using just one<br />

vehicle.<br />

Cargo areas/containers are<br />

equipped to suit the individual<br />

needs of our customers. This<br />

includes special refrigerated<br />

bar/counter containers,<br />

refrigerated beverage/food<br />

containers, containers for tents<br />

and equipment, or garbage<br />

containers. Everything is<br />

possible.<br />

Our CARGOLOADER ® vehicles<br />

are universal wizards. They are<br />

safe and easy to use. After<br />

receiving some brief<br />

instructions, the beverage shop<br />

owner and his staff are able to<br />

operate the special transport<br />

vehicle without any degree of<br />

difficulty. Even heavy and bulky<br />

Although the initial acquisition<br />

costs of the CARGOLOADER ®<br />

are higher than trucks with tail<br />

lifts, the follow-up costs are<br />

considerably lower. Because the<br />

entire cargo area can be loaded/<br />

unloaded so easily and due to<br />

the fact that so many different<br />

containers can be utilized, our<br />

CARGOLOADER ® vehicles pay<br />

off within a very short period of<br />

time. •<br />

Just like magic – and in no time at all – the container<br />

| 34<br />

at the fairground transforms into a complete<br />

beverage bar similar to the more traditional trailers that need to be towed to the venue by heavy trucks.

CUSTOMER INTERVIEW<br />

Beyer Mietservice places exclusive order<br />

with RUTHMANN<br />

When looking at innovative and efficient and application-oriented solutions, Beyer-Mietservice KG<br />

sets the trend and is continuously and systematically expanding: such as setting up new subsidiaries,<br />

offering pan-European renting or expanding its rental range. Once again the Beyer rental programme<br />